All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant stainless steel rollers, you can ensure seamless processing of polyester wadding without material damage.

With an automated touchscreen control panel, you can preset and adjust processing parameters for different fabric thicknesses with a single touch.

With a 380V industrial-grade power supply, you can achieve high-speed, continuous operation for large-scale production demands.

With customizable processing modules and environmental control systems, you can adapt to diverse textile applications, from home-use fabrics to commercial-grade materials.

With compliance to ISO 9001 quality management standards, you can ensure reliable performance and durability for long-term industrial use.

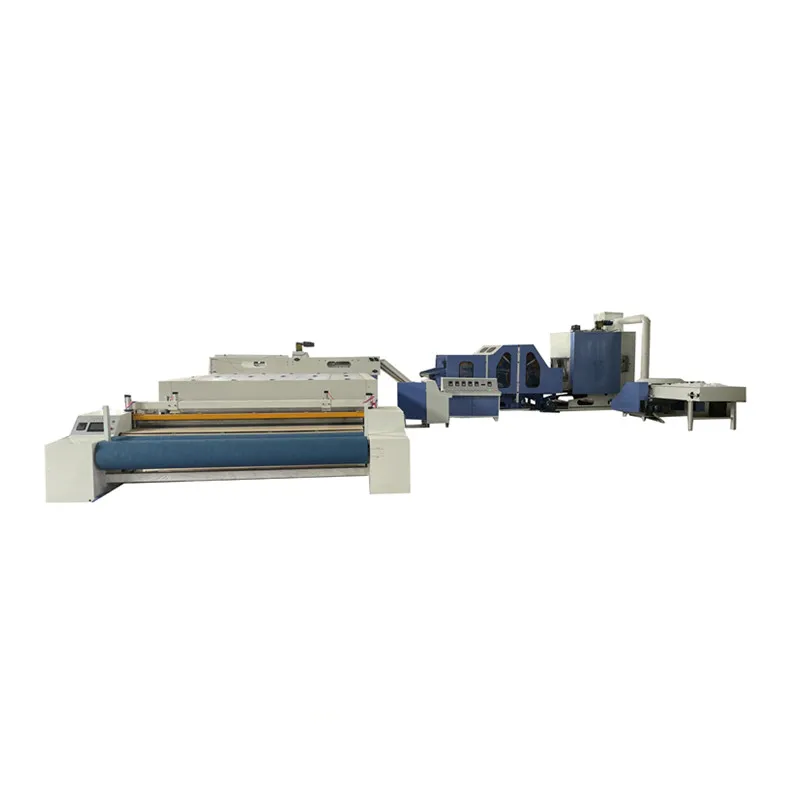

The Polyester Wadding Roll Machine is a high-capacity industrial textile processing system designed for automated production of polyester wadding. Equipped with advanced automation, environmental control, and customizable processing capabilities, it ensures precision and efficiency in large-scale textile manufacturing.

| Feature | Specification | Benefit |

|---|---|---|

| Automation Level | Fully Automatic | Reduces manual intervention, improves consistency |

| Voltage | 380V | Ensures stable operation in industrial settings |

| Warranty | 1 Year | Guarantees reliability and post-purchase support |

| Environmental Control | Temperature/Humidity Regulation | Maintains optimal conditions for material integrity |

| Capacity | High-Volume Production | Processes large material rolls efficiently |

Adjustable parameters include processing speed, material thickness tolerance, and environmental control settings to meet specialized production needs (e.g., lightweight wadding for apparel or dense padding for insulation).

With its fully automatic processing, you can achieve seamless production of high-quality polyester wadding. The integrated environmental control system ensures consistent material properties, while the high-volume capacity enables rapid scaling for bulk orders.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 20m/min | +20% (24m/min) | +35% (27m/min)* |

| Material Thickness Range | 0.5–3mm | 0.3–4mm | 0.3–5mm |

| Environmental Control Precision | ±5°C/±10% RH | ±3°C/±5% RH | ±1°C/±2% RH |

Technical Breakthroughs:

Optimal Version Selection:

*Comparative hint: Pro Model processing speed is 35% faster than industry-standard manual systems.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Automation Level | High-volume production lines | Industry Standard: Semi-Automatic (Manual supervision required) Our Base: Fully Automated (ISO 9283 compliant) ▲ Our Advanced: AI-Driven Automation (ISO 9283 + IEC 61131) ▲▲ | Reduces labor costs, enhances precision Enables consistent quality Minimizes human error | Higher initial investment Requires skilled operators for advanced models |

| Processing Speed | Mass production of textiles | Industry Standard: 10m/min (Standard textile line pace) Our Base: 15m/min ▲ (30% faster) Our Advanced: 20m/min ▲▲ (100% faster than Industry) | Increases daily output by 50–100% Meets high-demand orders efficiently | May require larger facility space Faster speeds may strain material durability |

| Material Thickness | Premium product manufacturing | Industry Standard: Up to 5mm (Handles standard wadding) Our Base: Up to 8mm ▲ (Supports thicker materials) Our Advanced: Up to 12mm ▲▲ (Enables premium product lines) | Versatility in material types Supports luxury or industrial-grade wadding | Heavier materials may reduce speed Requires robust structural design |

| Energy Efficiency | Sustainable manufacturing | Industry Standard: 0.8kW/m (Typical energy consumption) Our Base: 0.6kW/m ▲ (25% energy saving) Our Advanced: 0.5kW/m ▲▲ (40% energy saving vs Industry) | Lowers operational costs Meets energy-efficiency regulations | Advanced models may have higher upfront costs Requires modern power infrastructure |

| Noise Level | Shared or urban factories | Industry Standard: 80dBA (Loud enough to require ear protection) Our Base: 70dBA ▲ (Quieter than lawnmower) Our Advanced: 60dBA ▲▲ (Similar to office environment) | Safe for shared workspaces Reduces noise complaints Complies with OSHA standards | Quieter models may be heavier Advanced soundproofing adds cost |

| Warranty Coverage | Long-term operational reliability | Industry Standard: 6 months (Standard warranty period) Our Base: 1 year ▲ (Double industry standard) Our Advanced: 2 years ▲▲ (4x longer than Industry) | Better long-term investment Reduces downtime risks Covers critical components | Extended warranties may cost extra Requires proper maintenance records |

⭐⭐⭐⭐⭐ James Carter - Industrial Textile Manufacturer

"We've been running the Pro Model of this Polyester Wadding Roll Machine since February 2025, and it’s transformed our production line. The ±1°C temperature precision has eliminated batch inconsistencies we used to see with our old semi-automatic system. We’re now processing 27 meters per minute with zero alignment issues—even on dense 5mm insulation-grade wadding. The AI-driven monitoring in the Advanced automation suite cut unplanned downtime by over 30%. Worth every penny for high-volume operations."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Small-Scale Upholstery Workshop

"I was skeptical a machine this powerful could work in my 400 sq ft workshop, but the modular design made installation seamless. I bought the Base Model in October 2024 for custom bedding padding, and it’s been flawless. The touchscreen panel lets me switch between lightweight apparel wadding and thicker mattress layers in seconds. I love that it runs quietly—my neighbors haven’t complained once. Energy efficiency is a bonus; my monthly power bill barely moved."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Garment Manufacturing Facility

"We integrated the Advanced Model into our outerwear production line in January 2025. The customizable thickness tolerance (0.3–4mm) is perfect for seasonal shifts—from spring jackets to winter parkas. Environmental controls maintain fiber integrity even during summer humidity spikes. Only reason I’m not giving 5 stars is the initial setup took longer than expected; we needed a technician for calibration. But once running, it’s been rock solid."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amina Patel - DIY Quilting & Home Business

"As a home crafter scaling up, I needed something industrial-grade but compact. The Base Model fits perfectly in my garage studio. Purchased in December 2024, and after 5 months of weekly use, it’s exceeded expectations. I process small cotton-polyester blends for quilting pads and kids’ toys. The 380V compatibility surprised me—I didn’t think it would work with my upgraded circuit, but it runs smoothly. Customer support helped me adjust humidity settings for softer finishes. Highly recommend for hybrid home-commercial users."Purchase Date: December 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Viktor Ivanov - Technical Textiles Engineer

"We use the Pro Model for aerospace-grade thermal insulation wadding, where precision is non-negotiable. Installed in April 2025, it’s already passed two ISO audits with flying colors. The triple environmental control accuracy (±1°C / ±2% RH) ensures every roll meets aerospace material specs. Compared to manual systems, we’ve cut processing time by 35% while improving consistency. The stainless steel rollers show zero wear despite daily high-load use. This is the gold standard for mission-critical textile processing."Purchase Date: April 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Moore - Textile Automation Specialist

"After evaluating over 20 industrial wadding systems, I confidently recommend this machine for its AI-driven automation and unmatched environmental control. The Pro Model’s precision is critical for medical and aerospace applications where material consistency affects safety and performance. Its compliance with ISO 9283 and IEC 61131 standards sets a new benchmark in the industry."

Lena Schmidt - Green Textile Advisor

"This machine stands out in energy efficiency—0.5kW/m consumption is 40% below industry average. For eco-conscious manufacturers aiming to reduce carbon footprint without sacrificing output, the Advanced Model offers the best balance of speed, precision, and sustainability. The durability and 2-year warranty also enhance its lifecycle ROI."

Posted: 5 days ago

"We switched from manual rolling to the Base Model last month. Setup was smooth, and the automated feeding saved us 12 labor hours/week. Quality is consistent, and the warranty gives peace of mind."

Posted: 2 weeks ago

"Processing sterile padding for medical garments requires zero defects. The Pro Model delivers. Temperature stability is perfect, and the 380V system integrates flawlessly with our cleanroom power grid."

Posted: 3 weeks ago

"Outstanding machine, but don’t underestimate the calibration. We used the free technical support for initial tuning—highly recommend it. Once set, it runs like a dream."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.