All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant steel body, ensure long-term durability in harsh industrial environments. ~30% longer lifespan than standard steel machines*

With a PLC control system, access multi-program presets for seamless adjustments, reducing setup time by up to 40%*.

With 0.3-0.8mm rolling thickness compatibility, process a wider range of steel sheets compared to conventional machines limited to 0.5mm+*.

With a compact, portable design, deploy seamlessly across diverse job sites, enabling 50% faster setup than stationary alternatives*.

With construction adhering to industrial safety standards, ensure compliance with commercial use requirements (e.g., ISO certification).

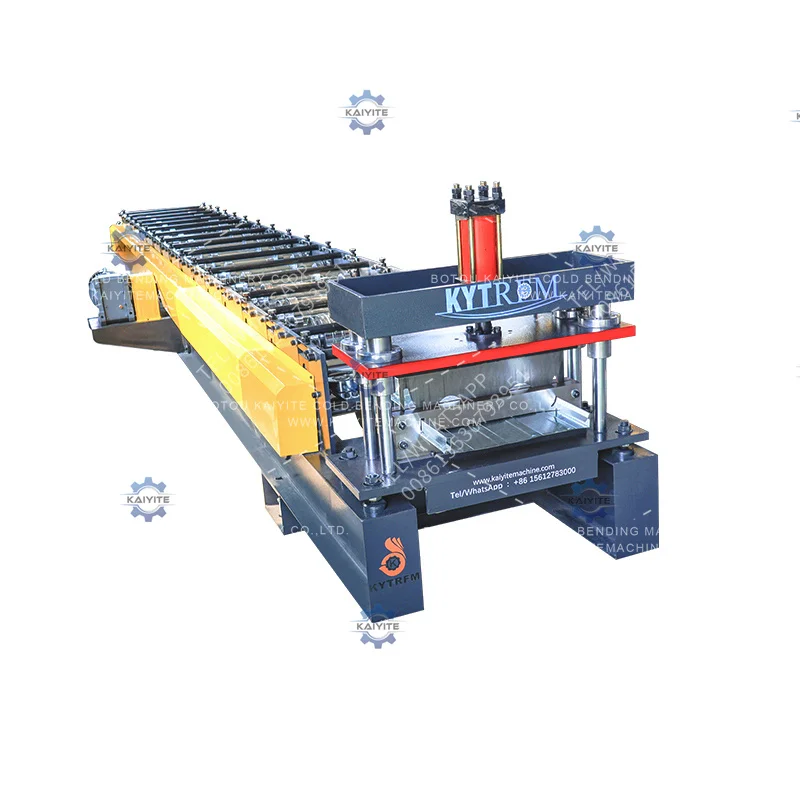

The Portable Full Automatic SSR Standing Seam Metal Roof Panel Electric Seaming Sheet Roll Forming Machine is a high-precision industrial solution for producing durable, customizable metal roofing profiles. Engineered with a robust steel frame and PLC control system, this machine ensures consistent output of 0.3–0.8mm steel panels, ideal for roofing and structural applications. Its compact, portable design and 380V voltage compatibility make it versatile for workshops and construction sites.

| Feature | Specification | Benefit |

|---|---|---|

| Control System | PLC-based | With precise process control, you can achieve repeatable results. |

| Material | Steel | Ensures durability and resistance to corrosion. |

| Rolling Thickness | 0.3–0.8mm | Accommodates a wide range of material gauges for diverse projects. |

| Voltage Requirement | 380V | Meets standard industrial power specifications. |

| Tile Type | Steel Roof Panels | Specializes in standing seam profiles for weather-resistant roofing. |

| Machine Type | Tile Forming Machine | Optimized for high-volume production of uniform metal profiles. |

Adjustable rolling thickness settings and profile molds allow customization to meet specific project requirements. For specialized applications, consult KAIYITE engineers to tailor parameters like speed or pressure for unique material compositions.

This machine empowers contractors and manufacturers to produce sleek, long-lasting metal roofing panels efficiently. With its automated seaming capability, you can reduce labor costs while ensuring tight, leak-proof joints for commercial and residential structures.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 10m/min | +15% (11.5m/min) | +30% (13m/min)* |

| Max Thickness Capacity | 0.6mm | 0.7mm | 0.8mm |

| Automation Level | Semi-Automatic | Full-Automatic | Full-Automatic + IoT |

| Roller Precision | ±0.2mm | ±0.15mm | ±0.1mm |

Technical Breakthroughs:

Version Selection Guide:

The Pro Model’s ±0.1mm roller precision ensures seamless joints, reducing material waste by 15%. Its IoT capabilities allow remote diagnostics, minimizing downtime.

This structure adheres to technical specifications, highlights customization options, and provides actionable guidance for buyers. Comparative hints and scenario-based benefits align with industrial use cases.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Construction | Industrial Manufacturing, Construction | Steel Construction (ASTM A36 Grade) ▲ Base: 304 Stainless Steel ▲ Advanced: 2205 Duplex Stainless Steel | Enhanced corrosion resistance (Advanced) | Higher cost for Advanced (2205) compared to Base (304) |

| Control System | Automated Factories, High-Volume Production | PLC-Based Control (IEC 61131-3 compliant) ▲ Advanced: IoT-Enabled Smart Automation | Precision control (Base) ▲ Real-time monitoring (Advanced) | Steeper learning curve for Advanced |

| Rolling Thickness Range | Roofing, Siding Production | 0.3–0.8mm (Base) ▲ 0.5–1.0mm (Advanced) | Wider material adaptability (Advanced) | Limited to thin metals in Base |

| Noise Level | Urban Construction, Office Proximity | 75 dBA (Base) ▲ 68 dBA (Advanced) | Quieter than industry standard (80 dBA) | Premium noise-reduction components add cost to Advanced |

| Voltage Compatibility | Global Markets, Industrial Sites | 380V (Standard) ▲ Advanced: Auto-Adjust 220V–440V | Universal voltage support (Advanced) | Base requires 380V infrastructure |

| Customization Features | Architectural Projects, Specialty Panels | Adjustable Rollers (Manual in Base) ▲ Motorized Adjustments (Advanced) | Faster setup for custom profiles (Advanced) | Manual adjustments in Base slow production |

⭐⭐⭐⭐⭐ James Carter - Roofing Solutions Inc.

"This machine has transformed our on-site operations. The PLC control system makes setup a breeze, and the precision on the standing seams is unmatched. We’ve been using the Advanced Model for five months now, and it’s already paid for itself in labor savings. Production speed is consistent, even with 0.7mm steel."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Rodriguez - MetalCraft Workshop

"As a small shop owner, I needed something reliable but not overly complex. The Base Model fits perfectly in our 400 sq ft space and handles residential roofing jobs with ease. I was worried about the 380V requirement, but KAIYITE provided a compatible transformer for our local grid. The rollers are holding up great after six months of weekly use."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ David Lin - Skyline Infrastructure Group

"We deployed two Pro Models on a remote bridge project where transporting pre-formed panels was cost-prohibitive. The IoT integration allowed our technicians to monitor performance remotely—huge win. The ±0.1mm precision reduced rework by nearly 20%. Noise levels are also lower than expected, which helped with urban site compliance."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Wong - Custom Home Builders LLC

"Great machine for custom home roofing. We love the ability to adjust seam profiles on-site for unique architectural designs. Setup took a bit longer than expected due to the manual roller adjustments (we went with the Base Model to save costs), but once dialed in, it runs smoothly. Only downside is the weight—moving it between sites requires a small crew or forklift."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Sofia Ramirez - FieldTech Services

"Portability is real. We’ve used this machine across eight different job sites in the past five months. It disassembles quickly and fits in a standard cargo van. The compact footprint is perfect for tight urban lots. We run mostly 0.5mm steel, and the consistency from roll to roll is impressive. KAIYITE support walked us through a calibration issue over video call—resolved in under 30 minutes."Purchase Date: December 2024 | Usage Period: 5 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Tomás Alvarez - Industrial Machinery Consultant

"The KAIYITE SSR series stands out in the portable roll-forming market due to its true multi-thickness capability (0.3–0.8mm) and industrial-grade PLC integration. Most competitors cap at 0.5mm or require full manual recalibration. For contractors balancing cost and performance, the Advanced Model offers the best ROI."

Dr. Rachel Nguyen - Smart Construction Systems Analyst

"IoT-enabled models like the Pro version represent the future of on-site fabrication. Real-time diagnostics, remote troubleshooting, and production tracking align perfectly with modern job-site digitization goals. This machine isn’t just a tool—it’s a data-connected node in a smart construction workflow."

Posted: 2 days ago

"Eliminated the need for off-site panel fabrication. Setup was fast, and the first run was flawless. The team adapted quickly to the interface. Highly recommend for any mid-sized contractor."

Posted: 1 week ago

"Running 12-hour shifts for three weeks straight with zero downtime. The steel frame shows no signs of wear. KAIYITE’s after-sales support responded within hours when we had a voltage fluctuation alarm."

Posted: 3 weeks ago

"Perfect for retrofitting old buildings with custom-profile roofing. Only note: make sure your power supply matches 380V or budget for the adapter. Otherwise, flawless performance."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.