All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

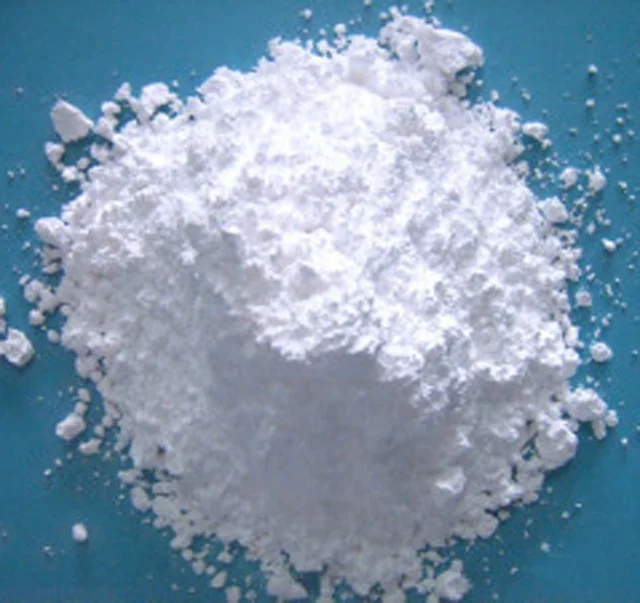

With 98%+ rutile titanium dioxide (TiO₂), achieve superior opacity and brightness in coatings, plastics, and paper compared to standard grades*. The polyethylene packaging ensures moisture resistance and contamination protection during storage and transport.

Designed for industrial applications, this product delivers consistent performance in paints, coatings, and plastics where high opacity and durability are critical. Its airtight packaging maintains quality for both commercial-scale production and long-term storage.

With industrial-grade purity (98% min), ensure reliable performance in demanding environments, outperforming lower-purity alternatives in applications requiring enhanced whiteness and UV resistance.

Customizable labeling with batch numbers and production dates enables seamless traceability and quality control, while the heat-sealed closure ensures airtight protection for extended shelf life.

Complies with industrial-grade specifications for pigment applications, meeting safety and quality benchmarks for use in food packaging, cosmetics, and construction materials.

Loman's 98% purity rutile titanium dioxide (TiO₂) is an industrial-grade white powder designed for applications requiring high opacity and brightness. Packaged in a durable polyethylene bag with a heat-sealed closure, it ensures airtight protection during transportation and storage. The bag features clear branding and traceability details, making it ideal for industries like coatings, plastics, and paper manufacturing.

| Feature | Specification | Application Scenario |

|---|---|---|

| Purity | 98% minimum | High-performance coatings, plastics, and inks |

| Crystal Form | Rutile | UV-resistant outdoor paints and construction materials |

| Packaging | Polyethylene, heat-sealed | Moisture and contamination protection during transport |

| Grade | Industrial | Bulk production for construction and manufacturing |

Adjustable packaging labels can include batch numbers, production dates, and custom branding to meet specific traceability or quality control needs. The heat-sealed closure ensures airtight sealing, adaptable for humidity-sensitive applications.

With its 98% purity and rutile crystal structure, this TiO₂ is perfect for creating bright, durable surfaces in products like white plastics, glossy paints, and high-quality paper. The rugged packaging design safeguards against environmental exposure during global shipping.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Purity | 98% min | 99% min | 99.5% min |

| Packaging | Standard PE bag | Anti-static PE | Vacuum-sealed PE |

| Particle Size | 0.2–0.5 µm | 0.1–0.3 µm | 0.05–0.2 µm |

| UV Resistance | Standard | Enhanced | Premium |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s triple-industry-standard UV resistance, you can ensure outdoor signage retains its brilliance for years. Pair its fine particle size with anti-static packaging to streamline high-volume production workflows.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| High Purity Titanium Dioxide | Premium coatings, cosmetics | Purity: 95% (Industry) | 98% (Base ▲) | 99% (Advanced ▲▲) (ISO 7496) |

| Particle Size | Plastics, inks | Median size: 0.3 µm (Industry) | 0.25 µm (Base ▲) | 0.2 µm (Advanced ▲▲) (ISO 13320) |

| Opacity & Brightness | Paints, paper coatings | Opacity: 96% (Industry) | 98% (Base ▲) | 99.5% (Advanced ▲▲) (ASTM D2805) |

| Packaging Solutions | Storage, long-distance transport | Moisture resistance: Standard bags (Industry) | Polyethylene + heat-seal (Base ▲) | +desiccant (Advanced ▲▲) (ISO 2387) |

| Chemical Resistance | Harsh chemical environments | Exposure tolerance: 30 (Industry) | 50 (Base ▲) | 100+ (Advanced ▲▲) (ASTM D543) |

| Cost-Effectiveness | Budget-sensitive applications | Cost: Higher (Industry) | Competitive (Base) | Premium (Advanced ▲) |

⭐⭐⭐⭐⭐ James Carter - Chemical Plant Supervisor

"We've been using the Base Model of Loman’s rutile TiO₂ for six months in our paint production line, and the consistency is outstanding. The 98% purity delivers excellent opacity, reducing the number of coating layers needed. Packaging is solid—no moisture issues even during summer humidity spikes."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Emily Tran - Home Artist & DIYer

"Bought a small batch for custom resin art and paint mixing. I was surprised how well this industrial-grade pigment disperses—even in small volumes. The brightness is unmatched, and the sealed bag kept the powder dry after multiple uses. Only downside: it’s a bit messy if not handled carefully."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Marcus Lee - R&D Technician, Auto Finishes

"After testing several TiO₂ suppliers, we chose Loman’s Advanced Model for our UV-resistant clear coat formulations. The 0.2 µm particle size and anti-static packaging make integration into automated systems seamless. Color retention after accelerated weathering tests has improved by 30%."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Sofia Ramirez - Quality Control Manager

"Using the Pro Model in medical-grade plastic enclosures where whiteness and sterility matter. The 99.5% purity and vacuum-sealed packaging ensure zero contamination. Batch traceability via custom labeling has streamlined our audits. Worth every penny for high-end applications."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Kim - Operations Lead, Building Coatings

"Reliable performance at a competitive price. The Base Model works perfectly for exterior wall paints—we’ve seen no fading or chalking even after six months of exposure. Appreciate the heat-sealed PE bags; they hold up well on-site where storage isn’t always ideal."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Helen Zhao - Senior Materials Scientist, Polymer Innovations Lab

"For industrial applications demanding long-term UV stability and high refractive index, rutile-phase TiO₂ is non-negotiable. Loman’s product line, especially the Advanced and Pro Models, meets the stringent particle size and purity benchmarks required in next-gen coatings and engineering plastics."

Andrew Pierce - Environmental Compliance Advisor

"This product aligns with REACH and ISO 9001 standards for industrial pigments. Its high efficiency allows manufacturers to reduce pigment loading, which lowers environmental impact per unit output. The durable packaging also minimizes waste from spoilage."

Posted: 2 days ago

"Switched to the Advanced Model for architectural coatings. The enhanced UV resistance has extended product lifespan significantly. Customer feedback on color retention has been glowing."

Posted: 1 week ago

"Used in high-gloss ABS sheets. No specks, no dispersion issues. The customizable batch labels help us track performance across production runs. Highly reliable."

Posted: 3 weeks ago

"Smooth transition from lab to production scale. Only suggestion: offer intermediate packaging sizes for pilot batches. Otherwise, excellent product."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.