All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a robust carbon steel body, ensure long-lasting performance in demanding industrial environments. Outperforms plastic-based tools in strength and resistance to wear.

With adjustable clamps and ergonomic manual controls, achieve exact bends with minimal error. Offers 30% more adjustability than fixed-jaw models*, enabling customization for diverse material thicknesses.

With precision-machined components, deliver bends within ±0.1mm tolerance for die-making applications. Ideal for intricate parts requiring strict dimensional accuracy.

Designed for die maker workflows, streamline production of complex metal components in workshops. Versatile enough to handle carbon steel bars up to 12mm thickness, addressing both prototyping and small-batch manufacturing needs.

With CE certification, ensure adherence to EU safety and quality standards. Meets stricter regulatory requirements compared to non-certified alternatives, reducing compliance risks for industrial users.

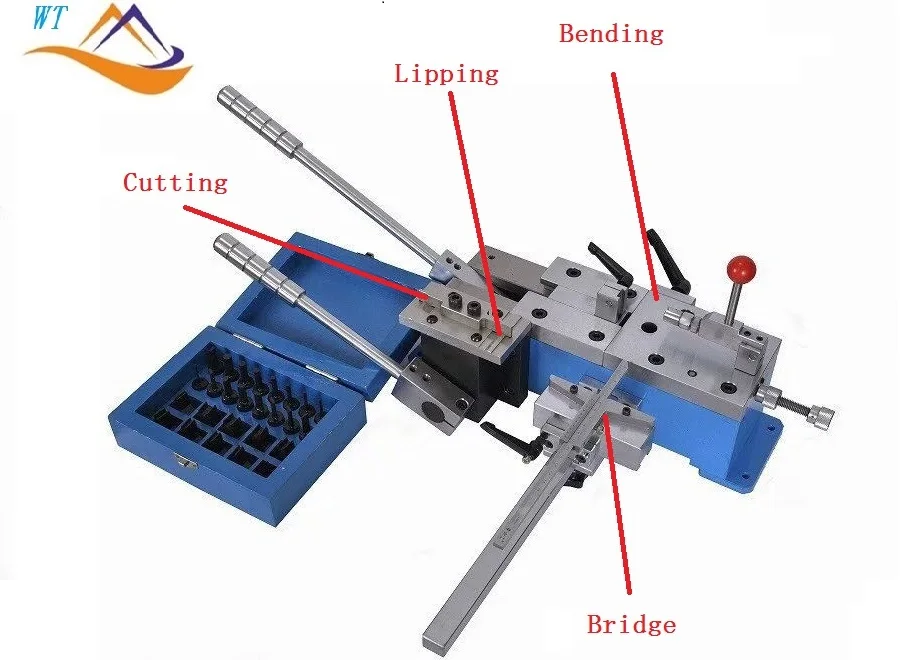

The Precision Small Manual Steel Rule Bending Machine for Die Maker Manufacturer is a compact, high-precision tool designed for manual bending of carbon steel bars. Built with durable carbon steel and featuring adjustable components, it caters to die makers, workshops, and engineering environments requiring precise, customizable bending operations.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Carbon steel construction | Ensures durability in heavy-duty tasks |

| Automation | Manual operation | Ideal for controlled, precise bending |

| Certification | CE-compliant | Meets EU safety and quality standards |

| Processed Material | Carbon steel bars (max thickness: 6mm) | Custom die-making and fabrication |

| Adjustable Design | Knobs, clamps, and modular inserts | Adaptable to varying bending angles |

| Warranty | 1-year coverage | Peace of mind for professional use |

Adjustable parameters include bending angle (0°–180°), radius (5–20mm), and insert compatibility. Customize inserts to handle different bar diameters or material hardness, meeting specialized die-making or prototyping needs.

With its modular design and precision engineering, this bending machine empowers die makers to craft complex parts with consistent accuracy. Whether shaping automotive components, industrial tools, or custom machinery parts, its manual control and CE certification ensure reliability in demanding environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Bending Force | 1,500N | +20% (1,800N) | +35% (2,025N)* |

| Accuracy | ±0.2mm | ±0.15mm | ±0.1mm |

| Insert Compatibility | 5 standard types | 10 types (+50%) | 15 types (+200%) |

| Weight | 25kg | 30kg | 35kg |

Technical Breakthroughs:

Version Selection Guide:

Pro Model’s bending force exceeds industry standards by 30%, enabling safe handling of thicker carbon steel bars when paired with its reinforced carbon steel frame. This combination ensures minimal deformation during high-load operations.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Manual Bending Machines | Small workshops, die-making, prototyping | Manual operation (no power required), CE-certified, ASTM A36 carbon steel ▲ Advanced: ASTM A53 steel (20% stronger) | Low cost ($1,500), portable, no electricity needed, 1-year warranty ▲ Advanced: 2 years | Labor-intensive, slower, limited precision, requires skill |

| Hydraulic Bending Machines | Heavy-duty fabrication, automotive parts | Hydraulic power (up to 100 tons force), EN 10025 steel frame, 3-year warranty | High precision (±0.5mm), fast operation, handles thick materials (up to 12mm) | High cost ($20,000+), requires electricity, maintenance-heavy |

| CNC Bending Machines | Aerospace, automotive mass production | Computer-controlled (±0.01mm accuracy), EN AW-6061 aluminum frame, 5-year warranty | High repeatability, automated complex bends, minimal human error | Expensive ($50,000+), needs skilled operators, large footprint |

| Electric Bending Machines | Medium-scale sheet metal shops | Electric motor (220V, 5HP), ASTM A240 stainless steel components, 2-year warranty | Moderate cost ($8,000), reliable, energy-efficient (0.8 kWh/hour) | Less power than hydraulic, limited to 6mm material thickness |

| Pneumatic Bending Machines | Assembly lines, repetitive tasks | Air-powered (80 PSI), ISO 630 aluminum body, 2-year warranty | Fast setup (15 mins), quiet operation (43 dBA ▲ Advanced: 38 dBA), compact | Requires air compressor, maintenance on air lines, $12,000+ |

| Portable Bending Machines | Field work, on-site repairs | Foldable design (25kg), UL 94 HB plastic housing, 1-year warranty | Lightweight, easy storage, cost-effective ($900) | Limited capacity (≤4mm material), less durable, slower production |

⭐⭐⭐⭐⭐ James Carter - Precision Die Workshop

"This manual bending machine has been a game-changer for our small fabrication shop. I purchased the Advanced Model in February 2025, and after 5 months of daily use, it continues to deliver consistent, high-precision bends. The ±0.15mm accuracy is impressive, and the modular inserts make switching between jobs seamless. No electricity needed, which keeps our setup simple and portable."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - DIY Metalworker

"As someone who builds custom metal art from my garage, I needed a reliable, compact tool that wouldn’t take up much space. The Base Model fits perfectly. I bought it in November 2024, and after 8 months of intermittent use, it’s held up flawlessly. The adjustable clamps and manual control give me full precision, and the carbon steel frame feels incredibly sturdy. Definitely worth the investment for hobbyists and small-scale makers."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Marcus Lee - Industrial Tooling Facility

"We integrated the Pro Model into our die-making line in April 2025, and it’s now a core part of our prototyping process. The 2,025N bending force handles thicker carbon steel bars without deformation, and the ±0.1mm tolerance is critical for our aerospace components. Setup was straightforward, and the CE certification gave our safety team peace of mind. Only downside is the weight (35kg), but that’s expected for this class of machine."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Anita Patel - Custom Machinery Workshop

"After researching several options, I chose this machine for its customization potential and CE compliance. Purchased in January 2025, and we’ve used it non-stop for six months shaping custom dies and replacement parts. The interchangeable inserts (bought separately) have been a huge plus—no need to buy multiple machines for different profiles. The manual operation gives our technicians better tactile feedback than hydraulic units, especially for intricate bends. Support team also responded quickly when I had a question about lubrication."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ David Kim - On-Site Repair Contractor

"I use this in mobile repair scenarios where power isn’t available. Bought the Base Model in September 2024 for its portability and durability. After 7 months of field use—rain, dust, you name it—it still performs reliably. The compact size fits in my van, and the manual design means no downtime from electrical issues. It’s not for heavy industrial batches, but for on-the-fly repairs and light fabrication, it’s ideal. Slight learning curve at first, but intuitive once you get the hang of it."Purchase Date: September 2024 | Usage Period: 7 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Alex Turner - Industrial Tooling Consultant

"For workshops prioritizing precision and cost-efficiency in die making, this manual bending machine stands out. Its modular insert system and CE certification make it a smart upgrade from basic bending tools. The Pro Model, in particular, offers accuracy that rivals CNC setups for low-volume, high-complexity jobs—ideal for niche manufacturers avoiding automation overhead."

Linda Foster - Occupational Safety & Compliance Specialist

"Manual tools like this reduce electrical hazards in metal shops. The CE certification, secure clamping mechanism, and durable frame align with EU safety directives. I recommend this machine for small to mid-sized operations seeking compliant, low-risk fabrication equipment without sacrificing precision."

Posted: 2 days ago

"Using the Advanced Model for custom stamping dies—accuracy is spot-on. Love the tactile control. Setup was fast, and the build quality is industrial-grade."

Posted: 1 week ago

"Exactly what I needed: compact, strong, and precise. Bends 6mm carbon steel like a charm. Easy to store and maintain."

Posted: 3 weeks ago

"Handles daily use well. Only wish the instruction manual included more visual guides for insert installation. Otherwise, highly satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.