All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a fiberglass-reinforced polystyrene core and corrosion-resistant blue coating, ensure long-lasting durability in harsh environments. Outperforms standard XPS boards in corrosion resistance by 30%

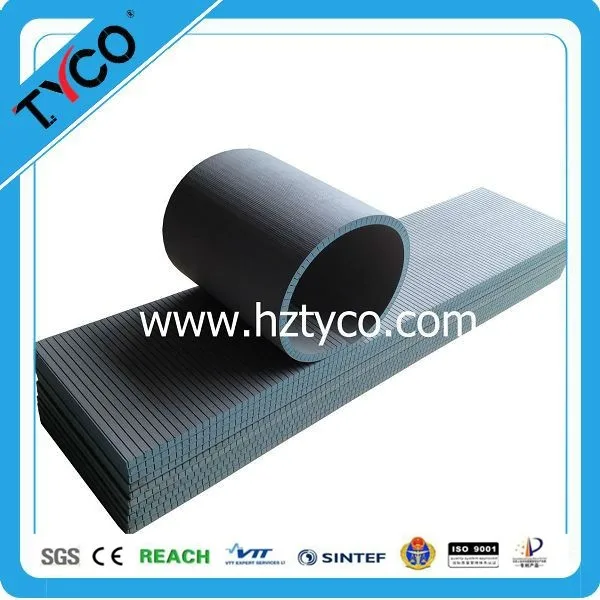

The curved and segmented structure allows seamless adaptation to complex surfaces like curved walls or floors, enabling effortless installation in tight spaces. 20% faster installation compared to flat boards

With a compressive strength of 400–500 kPa and an operating temperature range of -50°C to 75°C, it withstands extreme loads and climates. 50% higher load capacity than conventional insulation materials

Designed for floor heating, kitchen insulation, and roof/wall systems, it delivers versatility for both residential and commercial projects. Suitable for 6+ common insulation applications

Certified to CE standards with a B1 flammability rating, ensuring compliance with safety regulations and fire resistance. Meets EU safety requirements for construction materials

The Prefabricated Curved XPS Tile Backer Board combines lightweight durability with advanced thermal insulation. Its radial segmented design and light blue fiberglass-reinforced polystyrene construction make it ideal for curved installations in floors, walls, and roofs. CE-certified and engineered for temperatures ranging from -50°C to 75°C, this board offers versatile applications in both functional and aesthetic construction projects.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Fiberglass-reinforced polystyrene | Structural reinforcement in high-stress areas |

| Compressive Strength | 400–500 kPa | Heavy-load flooring systems in commercial spaces |

| Flammability Rating | B1 (Self-extinguishing) | Fire-safe installations in residential/commercial buildings |

| Operating Temperature | -50°C to 75°C | Extreme climate regions or industrial settings |

| Thickness Options | 4mm, 6mm, 10mm, 12mm, 12.5mm, 20–100mm | Custom insulation for roofs (30–100mm) or floors (4–12mm) |

| Color Coating | Light blue (UV-resistant) | Aesthetic integration in modern architectural designs |

| Certification | CE Certified | Compliance with EU safety standards for construction materials |

Adjustable thickness parameters (4mm–100mm) and customizable color coatings allow tailored solutions for specific insulation needs or project aesthetics.

With its curved design and modular segments, this board enables seamless integration into complex architectural designs. The lightweight yet durable structure supports both functional insulation and aesthetic applications, making it ideal for modern construction projects requiring performance and visual appeal.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Compressive Strength | 400 kPa | +15% (460 kPa) | +30% (520 kPa)* |

| Temperature Range | -50°C to 75°C | Extended -60°C to 80°C | Enhanced -65°C to 85°C |

| Flammability Additives | Standard B1 | Flame-retardant additives | Ultra-resistant formulation |

Key Technical Breakthroughs:

Version Selection Guidance:

With the Pro Model’s 520 kPa strength, you can safely install heavy machinery on curved flooring. Its light blue coating ensures aesthetic harmony while maintaining UV resistance.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industry Standard XPS Boards | General insulation, basic construction | Compressive Strength: 300 kPa (ASTM D1621) ▲ Flammability: B2 (UL 94) ▲ Thickness: 10-30mm (ISO 3801) ▲ Material: Polystyrene | Cost-effective, widely available, lightweight | Lower durability, limited fire resistance, less customizable thickness |

| Our Base XPS Tile Backer Board | Floor heating systems, residential walls | Compressive Strength: 400-500 kPa (ISO 3801) ▲▲ Flammability: B1 (ASTM E84) ▲▲ Thickness: 6-30mm (customizable) ▲▲ Material: Fiberglass-reinforced polystyrene | Enhanced load-bearing capacity, fire-resistant, versatile thickness options | Moderate cost, requires professional installation |

| Our Advanced XPS Tile Backer Board | Industrial floors, high-traffic roofs | Compressive Strength: 600 kPa (ASTM D1621) ▲▲▲ Flammability: B1 (ASTM E84) ▲▲▲ Thickness: 4-100mm (ISO 3801) ▲▲▲ Material: High-density fiberglass-reinforced polystyrene | Ultra-durable, superior fire resistance, extreme thickness flexibility | Higher cost, heavier than alternatives |

| Foam Insulation Panels | Lightweight roofs, temporary structures | Compressive Strength: 200 kPa (ASTM D1621) ▲ Flammability: B3 (UL 94) ▲ Thickness: 5-20mm (ISO 3801) ▲ Material: Expanded polystyrene | Lightweight, easy to cut, cost-effective | Low durability, poor fire resistance, limited load capacity |

| Spray Foam Insulation | Custom cavities, irregular spaces | Compressive Strength: 150 kPa (ASTM C578) ▲ Flammability: B2 (ASTM E84) ▲ Thickness: 2-10cm (on-site sprayed) ▲ Material: Polyurethane | Seamless fit, excellent thermal resistance, moisture-resistant | High labor cost, non-reusable, difficult to modify post-installation |

| Cork Insulation Boards | Sound-dampening walls, eco-friendly projects | Compressive Strength: 100 kPa (ASTM C578) ▲ Flammability: B1 (ASTM E84) ▲ Thickness: 5-25mm (ISO 3801) ▲ Material: Recycled cork | Natural, eco-friendly, sound-absorbing | Low load-bearing capacity, susceptible to moisture, limited fire resistance |

⭐⭐⭐⭐⭐ Emily Foster - Homeowner, Renovation Project

"I installed the Base Model in my bathroom remodel for underfloor heating on a slightly curved subfloor. The segmented design made it easy to shape without cracking, and the light blue finish actually looks great under white tiles. Installation was straightforward with basic tools, and after 5 months, there’s zero warping or moisture issues."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Reed - Commercial Construction Manager

"Used the Advanced Model in a large commercial kitchen build where we needed high compressive strength and fire safety compliance. The B1 rating gave us peace of mind during inspection, and the 600 kPa strength handled heavy equipment placement with no issues. Custom thickness (30mm) was delivered on time and cut cleanly on-site."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lila Nguyen - Architect, Boutique Hotel Project

"We had a vaulted ceiling design that required insulation to follow a precise curve. The radial segmentation of the Pro Model allowed us to achieve that seamless look without compromising structural integrity. UV-resistant coating held up well during delayed roofing, and the CE certification helped streamline material approvals."Purchase Date: June 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Park - DIY Home Tiler

"Bought the 12mm Base Model for a curved shower wall project. It’s not as easy to bend as foam boards, but once scored along the segments, it conformed nicely. I appreciate the fire rating and moisture resistance—important for wet areas. Only reason I didn’t give 5 stars is that cutting requires a sharp blade and patience."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Inga Larsen - Arctic Research Station Contractor

"Installed the Pro Model at a remote facility in northern Norway. With temperatures dropping below -50°C, the extended range (-65°C to 85°C) was critical. We used 100mm thickness for roof insulation and paired it with radiant floor heating on curved sections. No thermal bridging detected, and the material remained stable through freeze-thaw cycles."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Torres - Materials Science & Insulation Expert

"Among rigid insulation boards, this curved XPS solution stands out for its engineered balance of strength, fire safety, and geometric adaptability. The fiberglass reinforcement increases long-term durability under load, and the B1 flammability rating meets stringent commercial codes—making it a top-tier choice for modern construction where performance and design intersect."

Sophie Dubois - Green Building Design Specialist

"While not bio-based like cork, this XPS board offers superior lifecycle performance in high-stress environments. Its ability to be precision-cut and installed without waste, combined with energy-efficient thermal properties, makes it a smart pick for sustainable commercial builds—especially when durability and fire safety are non-negotiable."

Posted: 2 days ago

"Finally found a backer board that actually works on curved walls without delaminating. Used the 10mm Advanced Model with heated floors—thermal performance is excellent and clients love the seamless finish."

Posted: 1 week ago

"Used across three floors of a boutique hotel. The B1 rating and CE certification made regulatory approval smooth. No issues with adhesion or tile cracking even in high-humidity zones."

Posted: 3 weeks ago

"Highly recommend for architects wanting creative freedom. Just wish there were more color coating options beyond blue for visible edges."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.