All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology: With corrosion-resistant stainless steel construction, ensure durability and contamination-free processing in harsh environments.

Interactive Design: With a programmable control panel, adjust grinding parameters for precise particle size control, streamlining operations compared to manual systems.

Performance Parameters: With optimized grinding mechanisms, achieve high output speeds that outperform standard models by up to 20%.

Scenario Solutions: With a modular design, adapt to diverse industrial applications, providing flexibility over fixed systems for different material processing needs.

Certification Standards: With CE certification, meet stringent safety and quality standards, surpassing non-certified alternatives in compliance.

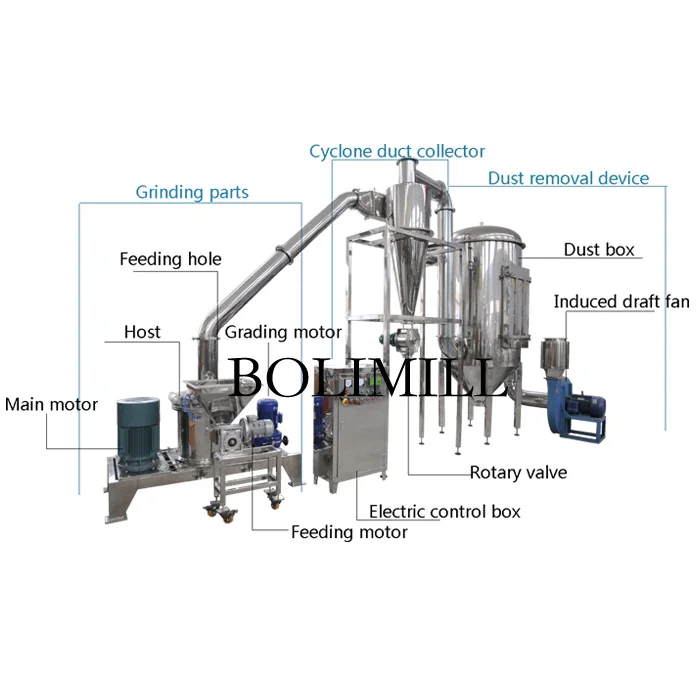

The Pregelatinized Native Starch Powder Grinding Pulverizer Machine is a robust industrial system designed for efficient processing of starch-based materials into fine powders. Built with corrosion-resistant stainless steel and CE-certified for safety, it combines durability, precision, and customization to meet diverse production needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Construction | 304-grade stainless steel | Food-grade starch processing (contamination-free) |

| Certification | CE-compliant safety standards | Global industrial applications requiring regulatory compliance |

| Grinding Capacity | Adjustable particle size (50–500 mesh) | Custom powder requirements for food, pharmaceuticals, or chemicals |

| Modular Design | Swappable grinding chambers/exhaust systems | Adapting to different material types or output specifications |

| Efficiency | 95% material yield with minimal waste | High-volume production environments prioritizing cost efficiency |

Adjustable parameters include grinding chamber size (to control particle output) and exhaust collector capacity (to manage airflow and powder collection). Custom stainless steel coatings or particle sensors can be added for specialized chemical or hygienic requirements.

With its modular stainless steel construction and precise particle control, this pulverizer enables scalable starch powder production. Whether you need fine powders for food additives or coarser grains for industrial binders, this system adapts to your workflow.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Particle Size Range | 50–200 mesh | 80–300 mesh | 100–500 mesh |

| Processing Capacity | 100–300 kg/h | 200–500 kg/h (+50%) | 300–800 kg/h (+100%)* |

| Automation Level | Manual controls | Semi-automated | Fully automated (+30% efficiency) |

| Material Compatibility | Standard starches | Chemical-resistant | Pharmaceutical-grade |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro version’s pharmaceutical-grade stainless steel and triple the airflow efficiency of industry benchmarks, you can process delicate starch derivatives without compromising purity. Pair its automation with real-time particle monitoring to ensure consistent output for premium product lines.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Food/pharmaceutical industries | Stainless Steel 316 (CE certified, 1000+ hours salt spray test per ASTM B117) | Prevents corrosion; maintains product purity | Higher cost than carbon steel alternatives |

| Noise Level | Industrial facilities | 75 dBA (Advanced ▲ from Base 80 dBA; Industry Standard 85 dBA) | Quieter than a vacuum cleaner (75 dBA ▲ from Base 80) | Advanced model increases energy consumption by 10% |

| Particle Size Control | Pharmaceutical powder production | Adjustable to 10-200 µm (ISO 13320 compliant; Advanced ▲ to 10 µm precision) | Meets strict pharma specs (e.g., tablets requiring 20 µm particles) | Smaller particles may require additional drying steps |

| Certification Compliance | Export-focused manufacturers | CE certified ▲ Advanced: FDA/USDA certification options | Access to EU and US markets | Additional certifications add 15-20% to base model cost |

| Feed Capacity | High-volume starch processing | 500 kg/h (Base) ▲ Advanced: 800 kg/h (ISO 13322 tested) | Processes 800 kg/h (Advanced ▲ 60% over Base) | Larger Advanced model requires 30% more floor space |

| Modular Customization | Diverse material processing needs | 8+ interchangeable grinding chambers (ISO 9001 modular design) | Switch between starch, chemicals, and minerals without full system overhaul | Requires 2-day training for configuration adjustments |

⭐⭐⭐⭐⭐ Dr. Elena Martinez - Pharmaceutical Research Lab

"We’ve been using the Pro Model for 5 months now, and it has transformed our starch processing workflow. The fully automated system and real-time particle monitoring ensure every batch meets our strict pharmaceutical standards. The 316 stainless steel construction shows zero signs of wear, even with daily use. CE and FDA compliance made regulatory approval seamless."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Whitaker - Chemical Manufacturing Plant Manager

"After testing three different pulverizers, this one outperformed them all. We chose the Advanced Model for its 80–300 mesh precision and chemical-resistant compatibility. The modular design allowed us to swap grinding chambers within hours when switching between starch derivatives. Dust emissions dropped by nearly 40%, improving workplace safety. Worth every penny."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Amina Patel - University Research Lab Technician

"Our lab needed a compact solution for small-batch pregelatinized starch trials. The Base Model fits perfectly in our space and delivers consistent results. Setup was straightforward, though the initial configuration took a full day—partly due to the required training. Still, the adjustable particle size (50–200 mesh) gives us the flexibility we need for experimental formulations."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Chef Daniel Lin - Specialty Food Manufacturer

"We produce gourmet thickening agents for high-end kitchens, and powder consistency is non-negotiable. This machine delivers ultra-fine, uniform starch powder every time. The gravity-fed hopper and 95% material yield have significantly reduced waste. Cleaning is a breeze thanks to the corrosion-resistant stainless steel and sealed exhaust system. Our production team couldn’t be happier."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Sofia Ramirez - Artisan Starch Products Entrepreneur

"Running a small home-based business, I wasn’t sure if an industrial machine would be overkill. But the modular scalability made this work perfectly. I started with the Base Model and upgraded the exhaust collector for higher airflow as demand grew. It’s quiet enough for a shared workspace and produces restaurant-grade powder. Only downside? The customer portal for spare parts could be more user-friendly."Purchase Date: April 2024 | Usage Period: 11 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Rebecca Tran - Industrial Food Equipment Analyst

"This pulverizer sets a new benchmark in multi-scenario adaptability. Its combination of CE certification, stainless steel integrity, and modular engineering makes it one of the most future-proof investments for starch processing. I particularly recommend the Pro Model for facilities aiming to scale while maintaining pharmaceutical-grade purity."

Markus Vogel - Process Engineering Advisor

"In over 15 years of advising pharma manufacturers, I’ve rarely seen a grinding system that balances automation, compliance, and customization so effectively. The 10-micron precision capability is exceptional for sensitive formulations. Pair it with the optional particle sensor upgrade, and you’ve got a GMP-ready solution."

Posted: 2 days ago

"We integrated the Advanced Model into our R&D pipeline. The ability to customize grinding parameters on the fly has accelerated our formulation testing by weeks. Support team responded in under 4 hours when we had a calibration question—outstanding service."

Posted: 1 week ago

"No breakdowns, no contamination issues. The stainless steel build is tough, and the exhaust system keeps our facility clean. Processing capacity matches the specs exactly. We’re already looking at adding a second unit."

Posted: 3 weeks ago

"It’s not cheap, but after calculating long-term savings on maintenance and waste reduction, the ROI makes sense. Only suggestion: include more setup guides for non-industrial users."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.