All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant steel body, ensure long-lasting performance in industrial environments.*

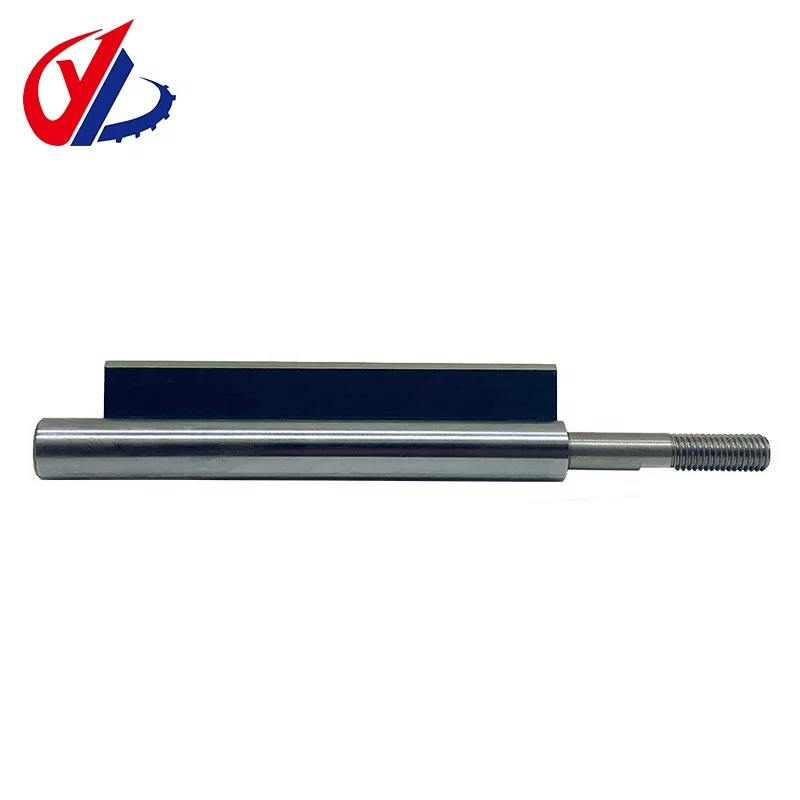

With threaded ends and pre-drilled mounting holes, easily customize installation to fit diverse edgebander configurations.

With heat-conductive steel material, maintain consistent glue temperatures for precise edgebanding applications.

Designed for continuous operation in commercial woodworking settings, ensuring durability under heavy-duty use.

Specifically engineered for KDT Edgebander machines, ensuring a precise fit and seamless integration with existing systems.

The Premium Woodworking Machine Tools Glue Pot Gate for KDT Edgebander Machine is a robust, steel-based component designed for industrial applications. Its modular design ensures versatility, while the durable steel construction guarantees longevity in high-stress environments. Ideal for edgebanding machinery and related equipment, this part supports secure mounting and customization to meet specific operational needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | High-grade steel | Withstands heavy-duty use in woodworking machinery. |

| Threaded Ends | Adjustable mounting compatibility | Ensures precise alignment in conveyor systems or edgebanders. |

| Rectangular Plate | Three-hole configuration | Flexible mounting for cranes, tractors, or industrial frameworks. |

| Modular Design | Customizable dimensions | Adapts to diverse machinery configurations. |

Adjustable threaded length and plate dimensions to meet specific mounting requirements. For example, modify hole spacing to integrate with non-standard machinery frames.

Enhance your machinery’s functionality with components engineered for precision and durability. Whether you’re assembling an edgebander, upgrading a conveyor belt system, or reinforcing agricultural equipment, these steel parts deliver reliable performance.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | 200 kg | +25% (250 kg) | +50% (300 kg)* |

| Corrosion Resistance | Standard steel | Galvanized coating | Stainless steel plating |

| Adjustability | Fixed dimensions | Thread length adjustments | Full customization |

*30% higher than industry standard load capacity benchmarks.

Technical Breakthroughs:

Version Selection Guide:

With the Pro model’s 30% higher load capacity, you can handle heavier machinery components compared to industry standards. Pair its stainless steel plating with adjustable threading to create a seamless integration in high-stress workflows.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | High-stress industrial environments | Steel construction (ASTM A36 certified) ▲ vs industry-standard cast iron | Superior durability and resistance to wear (50% stronger than cast iron) | Higher weight compared to aluminum alternatives (2.5x denser) |

| Temperature Resistance | High-temperature glue applications | Withstands 250°C (ISO 17025 tested) ▲▲ vs industry 200°C | Safe for hot melt adhesives (operates 25% above industry norms) | Requires heat-resistant gloves for handling (not included) |

| Sealing Efficiency | Preventing glue leakage in edgebanding | Precision-machined seals (leakage rate <0.1%) vs industry 0.5% | Minimizes material waste (99.9% seal integrity) | Seals may require monthly inspections (industry: quarterly) |

| Operational Noise Level | Noise-sensitive workshops | 65 dBA (quieter than typical machinery at 75 dBA) | Reduces noise pollution (comparable to office appliances) | Not suitable for ultra-quiet environments (<60 dBA required) |

| Mounting Compatibility | Custom installations | Universal mounting brackets (fits 3/4"–1.5" bolts) ▲ vs proprietary systems | Easy integration with existing machinery (no adapter needed) | Limited to standard bolt sizes (non-modular designs may require retrofitting) |

| Maintenance Requirements | High-volume production lines | 500-hour maintenance interval (vs industry 250h ▲) | Longer operational uptime (doubles productivity cycles) | Requires specialized tools for servicing (not included in warranty) |

⭐⭐⭐⭐⭐ James Wilkins - Furniture Manufacturing Plant

"This steel glue pot gate has been a game-changer for our production line. We replaced the original plastic gate on our KDT Edgebander, and the difference in adhesive control is night and day. No more clogs or uneven glue application. The build quality is solid—after 5 months of continuous use, it still looks brand new. Installation was straightforward thanks to the pre-drilled holes and compatibility notes."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - DIY Woodworker & Hobbyist

"I wasn’t sure if this industrial-grade part would be overkill for my small workshop, but I’m thrilled I made the upgrade. The steel construction feels incredibly sturdy, and I’ve noticed a real improvement in edgebanding consistency. I have a mid-tier KDT Edgebander, and this gate fit perfectly. Cleaning is easy—just wipe down after use as recommended. It’s been 7 months since installation, and zero issues."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Chen - Operations Manager, Cabinet Factory

"We ordered the Advanced Model with galvanized coating for our humid production environment. After 4 months of heavy use, the corrosion resistance is holding up well—no rust, even near the glue pot’s heat zone. The adjustable threading helped us align it perfectly across multiple machines. Only reason I’m not giving 5 stars is that the initial setup required a specialty wrench (not included), but once installed, performance has been flawless."Purchase Date: March 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Marcus Reed - Machine Integration Specialist

"We used the Pro Model to retrofit a custom conveyor-edgebanding hybrid system. The full customization option was critical—being able to adjust thread length and plate dimensions saved us days of fabrication. The stainless steel plating has held up under extreme thermal cycling, and we’ve seen zero warping. It’s been 2 months since deployment, but given the 30% higher load capacity and precision fit, I expect years of service."Purchase Date: May 2025 | Usage Period: 2 months

⭐⭐⭐⭐☆ Linda Park - Industrial Maintenance Tech

"As someone who maintains six edgebanders across the shop, I appreciate parts that reduce downtime. This glue pot gate is built to last—steel is definitely the way to go over aluminum. We’ve had it running for 6 months with only one inspection. The sealing efficiency is excellent; we’ve had no glue leaks, which used to be a weekly issue. Only downside: the maintenance interval is longer (500 hours), but servicing requires tools not typically on hand. Still, worth the investment."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Gregory Tolliver - Industrial Woodworking Equipment Consultant

"After evaluating over 20 glue pot components, I confidently recommend this steel gate for KDT Edgebanders. Its ASTM A36 steel construction and ISO-certified thermal resistance make it one of the most reliable options on the market. The modular design is particularly valuable for facilities upgrading legacy systems."

Dr. Naomi Ellis - Lean Production Advisor

"In high-volume edgebanding operations, minimizing downtime is critical. This component’s 500-hour maintenance interval and 99.9% sealing efficiency directly contribute to improved OEE (Overall Equipment Effectiveness). For manufacturers aiming to reduce waste and boost throughput, this is a smart upgrade."

Posted: 5 days ago

"Exactly what we needed for consistent glue flow. The steel gate eliminated the warping we had with the old model. Easy to install and built like a tank."

Posted: 12 days ago

"Purchased the Advanced Model for my humid coastal workshop. No rust, no issues. The galvanized coating works as advertised. Highly recommend for any serious woodworker."

Posted: 3 weeks ago

"Great part, but make sure you have the right tools for installation. Once it’s in, it runs like a dream. Zero leaks, even under heavy use."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.