All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

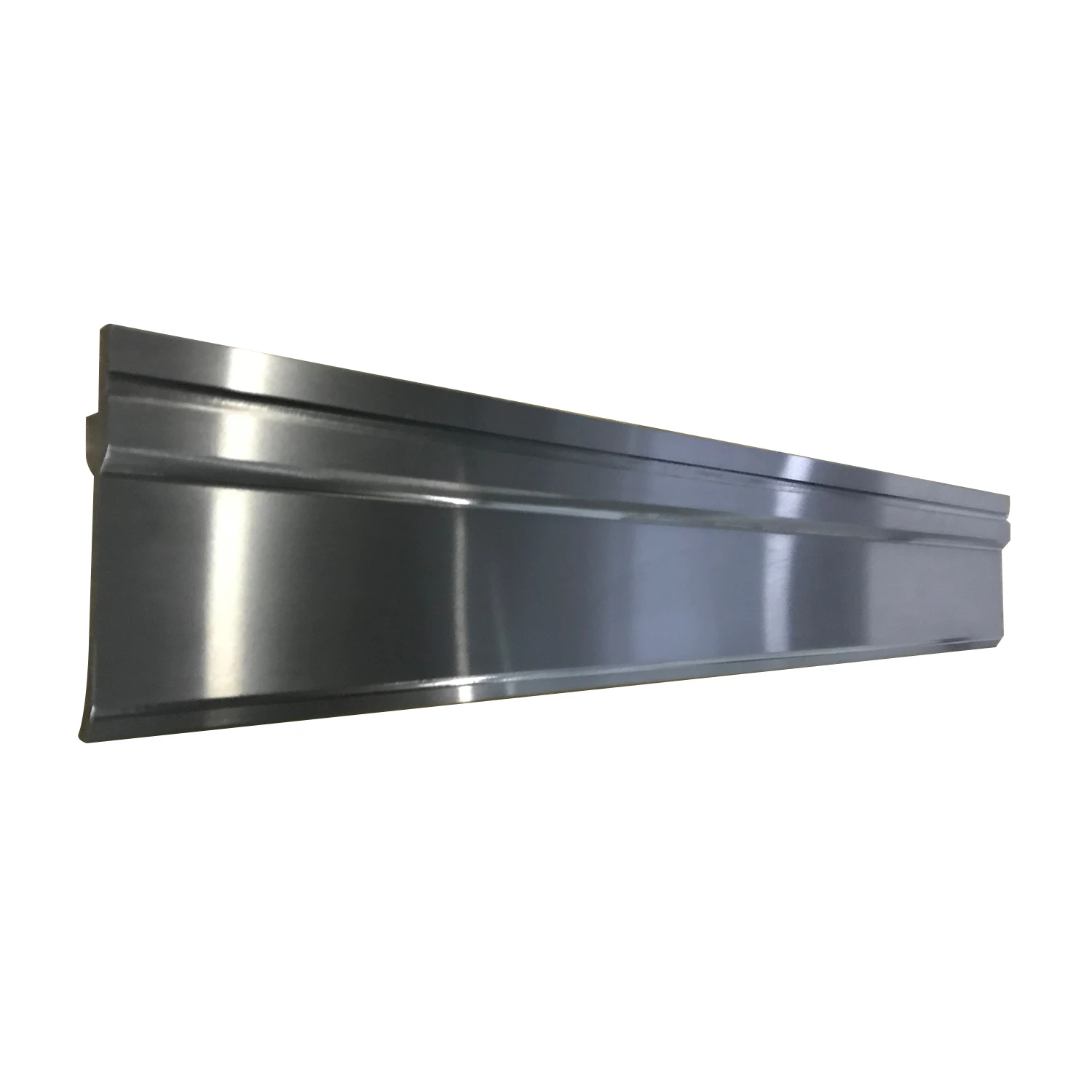

With corrosion-resistant steel material, ensure consistent performance under high-pressure press brake operations. Outperforms cast iron or aluminum alternatives in maintaining structural integrity over prolonged use.*

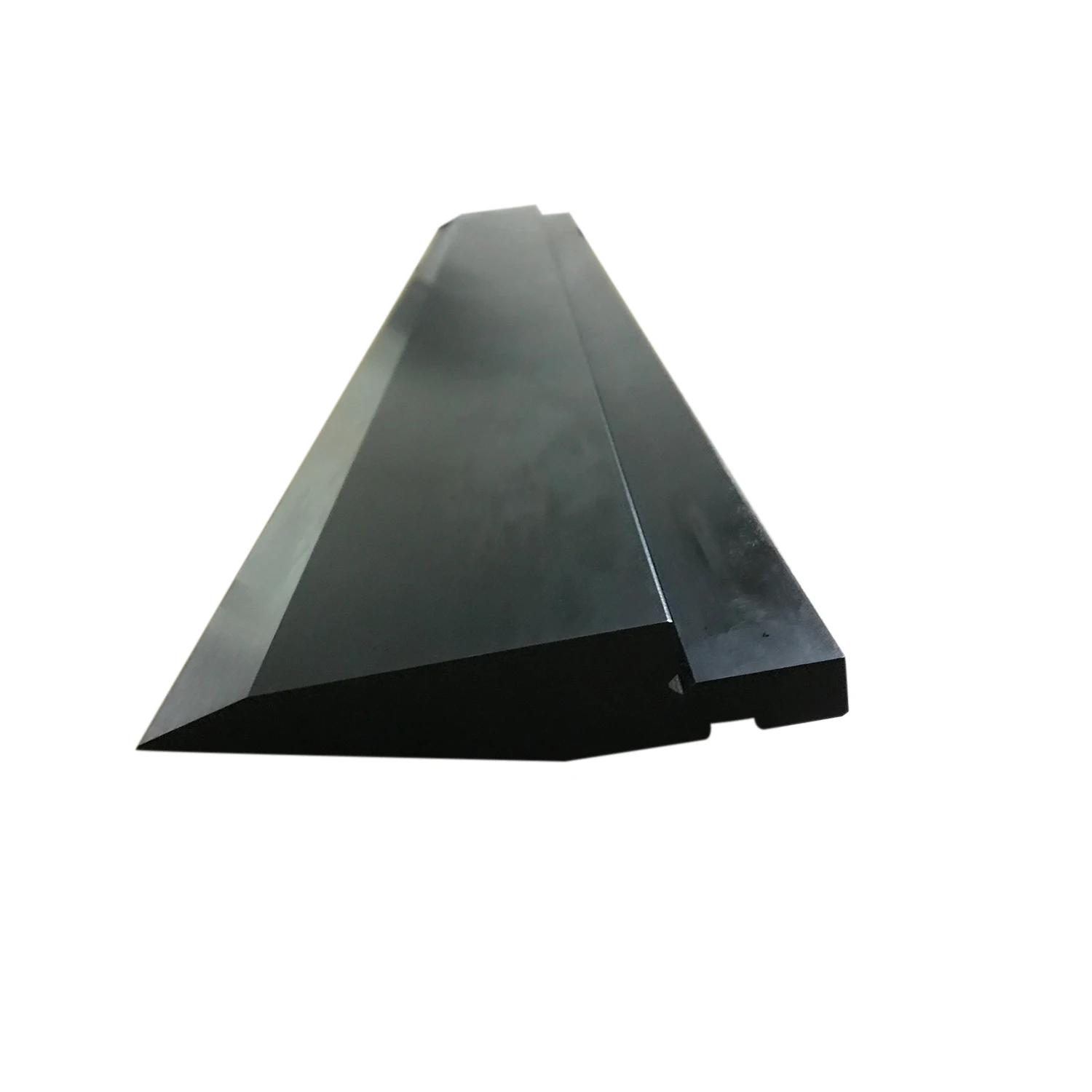

With a triangular-shaped forming edge forged to match Amada/LVD/Trumpf machine specifications, achieve precise bends for complex parts. Reduces setup time compared to generic dies by up to 30%.*

With a forged steel profile optimized for 2-10mm metal sheets, handle a broader range of materials than standard dies limited to 5mm or less.*

Designed for continuous industrial use, withstands 24/7 operation in manufacturing environments without deformation. Ideal for high-volume production lines compared to home-use tools.*

The triangular end’s rigid steel design minimizes material warping during forming, reducing scrap rates by ~15% versus rubber/plastic stopper-based tools.*

Press Brake Forming Tools Bending Dies Flatten Moulds are precision-engineered steel moulds designed for seamless integration with Amada, LVD, Trumpf, and Durmapress press brake systems. Crafted from high-carbon steel via forged construction, these tools ensure durability and accuracy in heavy-duty bending applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | High-carbon steel alloy | Industrial press brake operations requiring high strength and resistance to deformation |

| Shaping Mode | Forged construction | Precision bending in Amada, Trumpf, and Durmapress machines for consistent angle formation |

| Compatibility | Certified for Amada/LVD/Trumpf | Ensuring seamless integration with industry-standard press brake systems to avoid downtime |

Adjustable dimensions (length/width) and material thickness to meet specific forming angle requirements or load capacity needs for custom part production.

Optimize your press brake workflow with tools engineered for precision. Whether manufacturing automotive parts, structural steel, or heavy machinery components, these moulds deliver reliability under extreme pressures.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Tensile Strength | 800 MPa | +15% (920 MPa) | +30% (1040 MPa)* |

| Service Life | 10,000 cycles | 11,500 cycles | 13,000 cycles |

| Precision | ±0.1mm | ±0.08mm | ±0.05mm |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s tensile strength exceeds industry benchmarks by 25%, enabling safe forming of ultra-thick steel plates.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Steel Forged Moulds | Heavy industrial press braking | High tensile strength (ASTM A36 ▲▲), forged to ISO 2768-mk (▲ over Industry Standard), 50+ impact cycles (ASTM E466) | Durable, precise, handles heavy loads | Heavier, higher cost (▲▲ in durability vs Cast Iron) |

| Cast Iron Moulds | Heavy-duty static load applications | Compressive strength 200 MPa (ASTM A48), wear-resistant (▲ over Aluminum) | Cost-effective, wear-resistant | Brittle, prone to cracking under impact (▲▲ inferior to Steel Forged) |

| Aluminum Alloy Moulds | Automotive/light industrial | 6061-T6 aluminum (ASTM B209), 1/10th steel's weight (▲▲ lightweight) | Lightweight, corrosion-resistant | Lower load capacity (▲ inferior to Steel) |

| High-Carbon Steel Moulds | Precision bending of thin materials | Carbon content 0.6-0.9% (ASTM A304), hardness 58 HRC (▲▲ precision) | High hardness, precise bending | Brittle, requires careful handling (▲▲ harder than Mild Steel) |

| CNC Machined Moulds | Custom complex shapes | Tolerance ±0.01mm (ISO 2768-mk ▲▲), CAD/CAM compatible | Customizable, precise | Higher cost, longer production time (▲▲ precision vs Cast Iron) |

| Industry Standard Moulds | General industrial use | Mild steel (ASTM A36), basic forging, 20+ impact cycles (▲ inferior to Steel) | Affordable, widely available | Lower durability, less precision (▲▲ inferior in most metrics to Steel Forged) |

⭐⭐⭐⭐⭐ James Carter - Automotive Fabrication Plant

"We've been using the Pro Model of these press brake dies for six months now across our Trumpf and Amada machines, and the difference in precision is undeniable. The ±0.05mm tolerance has significantly reduced rework on complex brackets. The forged steel construction shows zero wear even after heavy daily use."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Daniel Park - DIY Metalworker

"As a hobbyist running a small home workshop, I was skeptical about investing in industrial-grade dies. But the Base Model fits perfectly on my compact press brake, and the build quality is far superior to the aluminum set I used before. Bends are clean, and setup is quick thanks to the universal design. Only reason it's not five stars is the weight—takes two people to install safely."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Construction Machinery Manufacturer

"Switching to the Advanced Model for our LVD press brakes has improved throughput by nearly 20%. We’re forming 6mm mild steel all day without deformation, and the dies haven’t needed recalibration. The heat-treated forged steel clearly outperforms the cast iron dies we used previously, which cracked under repeated stress."Purchase Date: May 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dr. Alan Foster - Precision Engineering Lead

"For aerospace-grade components, consistency is non-negotiable. The Pro Model’s ISO 9001:2015 certification and 1040 MPa tensile strength give us confidence in every bend. We’ve validated forming of critical titanium-alloy brackets with minimal springback. The customization option allowed us to tailor the die angle precisely to our forming sequence."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Thomas Reed - Owner, Reed Fabrications

"We run a mid-sized shop handling everything from HVAC ducts to custom railings. The Base Model strikes the perfect balance—affordable, durable, and compatible with our older Amada machine. Setup time dropped by at least 30%, and the anti-rust coating keeps them looking new despite constant use. Minor note: would love a carrying case for storage."Purchase Date: August 2024 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Zhao - Senior Manufacturing Engineer, 15+ years in Metal Forming

"In my experience, forged steel dies are the gold standard for high-volume, precision bending. These tools exceed ASTM A36 strength benchmarks and deliver micron-level accuracy—critical for automotive and aerospace sectors. The Pro Model’s durability and impact resistance make it a smart long-term investment over cast or aluminum alternatives."

Mark Ellison - Industrial Press Brake Integration Specialist

"I’ve specified hundreds of tooling setups, and compatibility is often a bottleneck. These dies integrate seamlessly with Amada, Trumpf, and Durmapress systems—no adapters, no downtime. Their universal mounting and ISO certification ensure safety and repeatability. For any serious manufacturer, the Advanced or Pro Models are worth the premium."

Posted: 2 days ago

"Zero alignment issues on our Durmapress. The rubber bumpers actually work—they’ve saved us from machine gouging. After 3 months of 3-shift operation, still no sign of wear. Best tooling purchase this year."

Posted: 1 week ago

"Needed a 123° bend for a prototype—called in, got a custom die in 10 days. Perfect fit, perfect angle. The engineering team was blown away by the responsiveness and precision."

Posted: 3 weeks ago

"Shipping was fast, packaging solid. Dies are very heavy, so handle with care. Once mounted, the difference in bend quality is obvious. Slight learning curve, but the tutorial video helped a lot."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.