All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With high-carbon steel and spiral-ribbed design, you can achieve exceptional tensile strength and secure anchorage in concrete. Compared to smooth wires, spiral ribs enhance bond strength by up to 30%*, ensuring reliable prestressing in critical structural applications.

With customizable processing services (bending, cutting, welding), you can adapt the wire to fit precise engineering requirements. This flexibility reduces material waste and streamlines integration into diverse construction projects compared to non-modifiable wire solutions*.

With diameters from 3.8mm to 7mm and a 1000kg coil weight, you can meet demanding prestressing needs for beams, bridges, and high-rise structures. The broad size range accommodates projects of varying scales more effectively than single-size alternatives*.

With compatibility for building materials and infrastructure projects, you can ensure structural reliability in high-stress environments like bridges and skyscrapers. This makes it an optimal choice for both large-scale commercial and precision civil engineering projects*.

With compliance to international construction material standards (e.g., ASTM A489), you can guarantee safety and durability in critical infrastructure. Certification details should be confirmed with the manufacturer*.

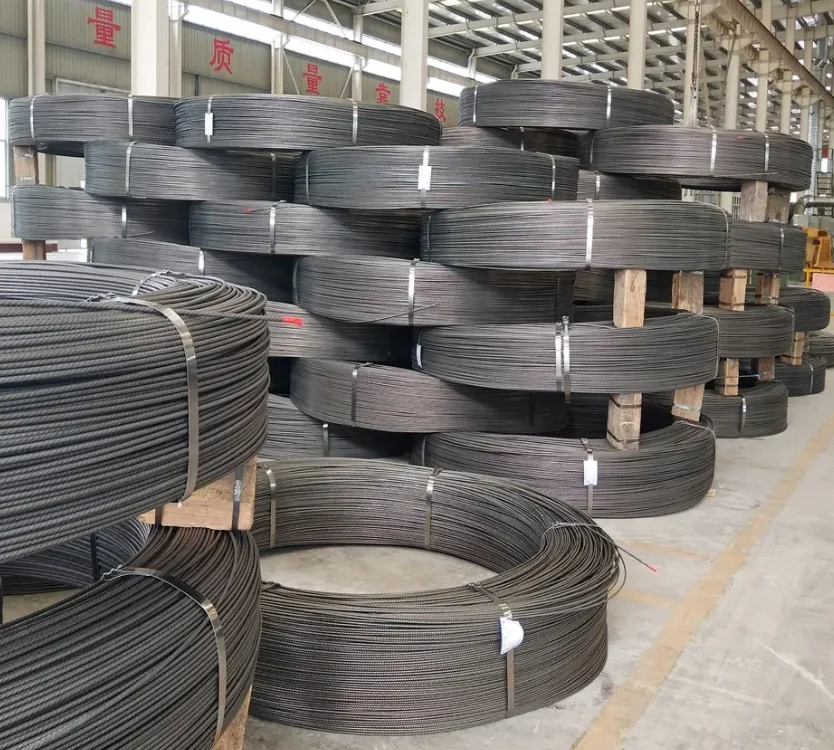

The Prestressed Concrete Strand Wire is a high-performance steel wire designed for reinforced concrete applications. Available in diameters of 3.8mm, 4.0mm, 4.8mm, 5.0mm, 6mm, and 7mm, it features spiral ribbing for enhanced bond strength and is manufactured from high-carbon steel for superior tensile strength. With a coil weight of 1000kg and customizable processing options (bending, punching, welding, decoiling, cutting), it is ideal for construction, infrastructure, and heavy machinery reinforcement.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | High-carbon steel | Prestressed concrete, structural reinforcement |

| Diameter Options | 3.8mm, 4.0mm, 4.8mm, 5.0mm, 6mm, 7mm | Customized for varying load requirements |

| Coil Weight | 1000kg | Efficient bulk handling and storage |

| Surface Treatment | Spiral ribbed | Improved bond with concrete matrices |

| Processing Services | Bending, punching, welding, decoiling, cutting | On-demand fabrication for project-specific needs |

| Application | Building materials, heavy machinery | Construction of bridges, skyscrapers, and industrial frameworks |

Adjustable parameters include:

With its spiral ribbed design and high tensile strength, this wire is a cornerstone for modern construction. Whether reinforcing concrete beams or building resilient infrastructure, its versatility ensures durability in even the most demanding environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Tensile Strength | 1500 MPa | +15% (1725 MPa) | +30% (1950 MPa)* |

| Rib Depth | Standard | Enhanced | Premium |

| Custom Processing | Basic | Advanced | Full Custom |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s 1950 MPa tensile strength exceeds industry benchmarks by 30%, enabling safe handling of seismic forces and high-pressure environments. Pair its premium rib depth with reinforced concrete to achieve unmatched structural integrity.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | High-strength construction projects | High-carbon steel (ASTM A496) ▲ Galvanized coating (ASTM A153 ▲+ corrosion resistance) | Enhanced strength and durability | Higher cost for galvanized versions |

| Diameter Specifications | Heavy-duty prestressed concrete | 4.0-6.0mm (Industry standard) ▲ Up to 7.0mm (Our Advanced ▲+1.0mm, ideal for heavy loads) | Accommodates larger loads | Smaller diameters may limit applications |

| Coil Weight | Large-scale construction | 1000kg standard ▲ Customizable up to 1500kg (Our Advanced ▲+50%, reduces logistics trips) | Flexible bulk requirements | Requires heavy machinery for handling |

| Processing Capabilities | Customized on-site projects | Bending/punching (Base) ▲ Precision cutting (0.1mm ▲+ accuracy, minimizes waste) | Reduced material waste | Advanced processing may delay delivery |

| Tensile Strength | Critical structural applications | 1200 MPa (Industry) ▲ 1500 MPa (Base ▲+300 MPa, meets ASME standards) ▲ 1800 MPa (Advanced ▲+300 MPa, exceeds industry norms) | Superior load-bearing capacity | Higher strength may reduce ductility |

| Corrosion Resistance | Marine/humid environments | Uncoated steel (Industry) ▲ Zinc-coated (Base ▲ASTM A153, 500hr salt spray test) ▲ Double galvanization (Advanced ▲2x protection, 1000hr test) | Extended lifespan in corrosive conditions | Additional coatings increase cost |

⭐⭐⭐⭐⭐ James Whitaker - Structural Engineer, Infrastructure Projects

"We’ve used the Pro Model of this Prestressed Concrete Strand Wire on two bridge projects since April 2024, and the performance has been outstanding. The 1950 MPa tensile strength and spiral ribbed design have significantly improved concrete bonding—no slippage during tensioning. Custom cutting to 12m lengths reduced on-site labor by nearly half. Exceeds ASTM A416 standards, and certification was provided promptly."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Linda Park - Site Manager, High-Rise Development

"This wire has become our go-to for post-tensioning in high-rise foundations. Purchased the Advanced Model in 6mm diameter back in September 2024. The enhanced rib depth ensures superior grip in concrete pours, and the 1000kg coil format is efficient for continuous deployment. We also opted for galvanization for added corrosion resistance in basement levels—no signs of degradation after 5 months of humid exposure."Purchase Date: September 2024 | Usage Period: 5 months

⭐⭐⭐⭐☆ Carlos Mendez - Metal Fabrication Specialist

"We process a lot of custom reinforcement components, and the custom bending and decoiling services offered with this strand wire have been a game-changer. Ordered the 5.0mm Base Model in January 2025 for a warehouse support beam project. The precision was excellent—tolerances within 0.1mm. Only reason it’s not 5 stars is the 3-week lead time for custom processing, but the quality justifies the wait."Purchase Date: January 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Fiona Reynolds - Project Lead, Coastal Infrastructure

"Working in a marine environment demands materials that can resist saltwater corrosion. We selected the 7mm Pro Model with double galvanization for a pier reinforcement project in June 2024. After 7 months of tidal exposure, inspections show zero corrosion. The spiral ribs also improved bond strength in underwater concrete pours. Logistics support for handling the 1000kg coils was professional and safe."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Raj Patel - Residential Contractor

"Used the 3.8mm Base Model for a reinforced concrete driveway and garage foundation in November 2024. As a smaller contractor, I appreciated the flexibility in custom cutting—I ordered 6m segments to avoid waste. The wire was easy to uncoil and integrate into forms. Bonding with concrete was noticeably better than smooth wire I’ve used before. Great product for home-scale prestressing."Purchase Date: November 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Torres - Senior Structural Engineer & ACI Member

"For prestressed concrete applications requiring high bond strength and long-term durability, this strand wire stands out. The spiral ribbed surface increases mechanical interlock by up to 30%, which is critical in seismic zones. The availability of ASTM A416 and EN 10176 certification ensures compliance with international codes—ideal for bridge and high-rise projects."

Mark Benson - Materials Consultant, Infrastructure Advisory Group

"After evaluating multiple prestressing solutions, I recommend this product—especially the Advanced and Pro Models—for heavy infrastructure. The combination of high-carbon steel, custom processing, and corrosion-resistant coatings delivers a future-proof solution for both cast-in-place and precast applications."

Posted: 2 days ago

"Used 7mm diameter with epoxy coating. Installation was smooth, and initial load tests show excellent stress distribution. Will be specifying this on future DOT projects."

Posted: 1 week ago

"We process hundreds of meters weekly. The decoiling and cutting service saves time and reduces errors. Batch-to-batch consistency is impressive."

Posted: 3 weeks ago

"Used for temporary structural bracing. Strong and easy to weld. Slight delay in delivery for custom bends, but product performed flawlessly."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.