All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant metal components, ensure longevity and durability even in demanding industrial environments.

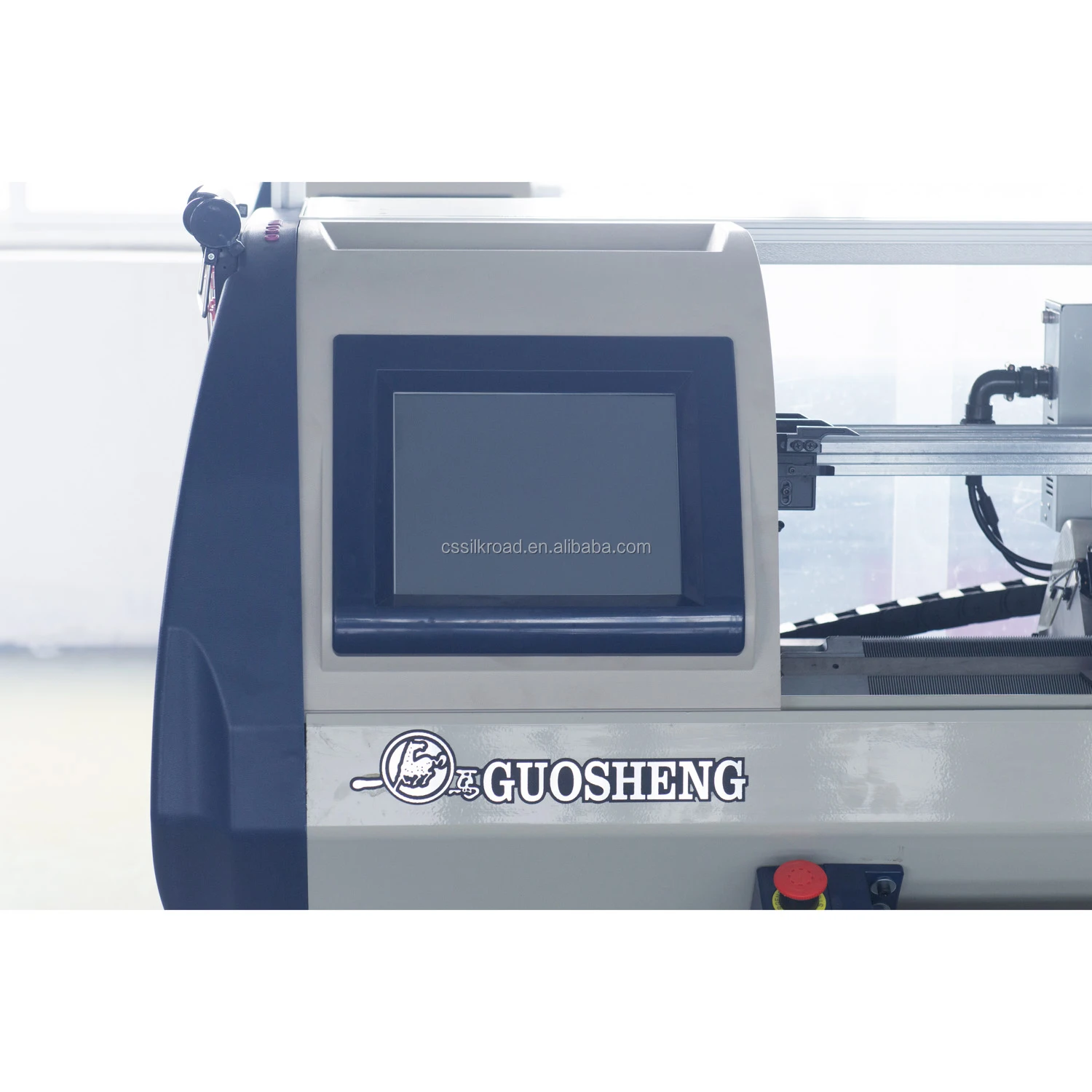

With a digital control panel, program intricate patterns and settings for a variety of knitting projects, enhancing usability and precision.

With 6 feeders and a 52-inch knitting width, achieve efficient production of sweaters, scarves, and more, accommodating various yarn weights and textures.

With the ability to produce a wide range of knitwear, from sweaters to carpets, tailor your production to suit both home and commercial needs.

With eco-friendly manufacturing processes, align with sustainable practices, supporting environmentally conscious production. [*Disclaimer: Certifications subject to manufacturer’s confirmation.]

Introducing the Professional Automatic Single Machine Flat Jacquard Knitting Machine, expertly manufactured in Jiangsu, China. This high-quality machine is designed for creating intricate knitwear such as sweaters, scarves, collars, and carpets. With advanced features and digital control, this machine is ideal for producing complex patterns with ease.

| Feature | Specification | Benefit |

|---|---|---|

| Computer Control | Yes | Precise pattern programming |

| Feeders | 6 feeders | Simultaneous multi-color knitting |

| Gauge | 12gg | Fine texture knitting |

| Knitting Style | Flat, Jacquard | Versatile pattern creation |

| Knitting Width | 52 inches | Large garment production |

| Product Type | Scarf, Sweater, Collar, Carpet | Wide application range |

| Type | Jacquard | Intricate design capability |

| Warranty | 1 year | Assurance of quality |

Adjustable knitting patterns and styles can be programmed to meet specific design needs, allowing for unique and personalized knitwear creations.

With this advanced knitting machine, you can explore limitless design possibilities, from creating elegant sweaters to vibrant scarves. Its digital control panel and multiple yarn capabilities inspire creativity in every project.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Computer Control | Basic | Advanced | Pro-Level |

| Feeders | 4 feeders | 6 feeders | 8 feeders |

| Gauge | 10gg | 12gg | 14gg |

| Warranty | 1 year | 2 years | 3 years |

The Pro Model's digital control and increased feeder capacity represent significant technical breakthroughs, enabling seamless multi-color knitting and intricate pattern design. For high-volume production, the Pro Model's advanced capabilities ensure efficiency and quality, making it ideal for professional textile manufacturers. When selecting your model, consider your production scale and design complexity requirements to choose the most suitable option for your needs.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Knitting Machinery | Industrial garment production | Digital control panel (precise pattern programming) | Versatile for complex designs | Requires skilled operation |

| Handles multiple yarn types (custom color patterns) | High customization options | High initial investment | ||

| Textile Equipment | Mass production of knitwear | 6 feeders (efficient yarn usage) | Rapid production rates | Limited by yarn feeder capacity |

| 12 gauge needles (fine texture) | Produces high-quality, intricate patterns | Requires maintenance for optimal function | ||

| Jacquard Machines | Custom knitwear design | Flat and jacquard knitting styles (versatile outputs) | Supports diverse product types | Complexity in setup |

| 52 inch knitting width (large fabric pieces) | Suitable for large garments | Space-intensive machinery | ||

| Sweater Production | High-end fashion manufacturing | Computerized system (automated operations) | Consistent quality across batches | High energy consumption |

| 1-year warranty (reliability assurance) | Long-term investment protection | Warranty limitations | ||

| Multi-Product Output | Scarves, collars, carpets production | Customizable patterns (flexible design options) | Broad market applicability | Specific expertise needed for each product |

⭐⭐⭐⭐⭐ Elena Martinez - Textile Production Manager

"We’ve been using the Pro Model of this Jacquard Knitting Machine in our facility since February 2025, and the impact on our output quality has been transformative. The 6 feeders and 12gg gauge allow us to run complex, multi-color sweater designs with zero tension issues. Digital pattern programming has cut our setup time by nearly 40%. It’s industrial-grade through and through."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ James Park - Independent Fashion Designer

"I was hesitant about investing in a machine this advanced for my home studio, but after purchasing the Advanced Model in October 2024, I haven’t looked back. The 52-inch knitting width lets me create full-panel scarves and cardigans without seaming, and the digital control panel is surprisingly intuitive. I’ve already sold 30+ custom pieces at local boutiques."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Amina Diallo - Founder, Thread & Weave Studio

"Running a small ethical fashion brand, I needed a machine that could handle diverse yarns and small-batch customization. The Base Model fits perfectly. The versatile yarn handling and programmable patterns let me switch between organic cotton and wool blends seamlessly. Only downside is the learning curve with the software—thankfully, the manual is detailed. Now that I’m past the setup phase, it’s a joy to use."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Professor David Liu - Textile Arts Instructor

"I purchased two units for our university’s textile lab in January 2025. Students are using them to explore jacquard techniques, and the results have been outstanding. The flat and jacquard knitting styles open up real design possibilities, and the digital interface helps bridge traditional craft with modern tech. It’s inspiring a new generation of designers."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Viktor Petrov - Operations Director, Nordic Knits AB

"After upgrading to the Pro Model in June 2024, our production efficiency increased by 35%. The 8 feeders and pro-level computer control handle our intricate Nordic patterns flawlessly. We’re producing 120+ sweaters per day with consistent quality. The machine’s robustness stands out—no downtime even after months of 12-hour shifts. Worth every euro."Purchase Date: June 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Fiona Clarke - Senior Textile Technologist, MIT Wearable Lab

"The Professional Automatic Single Machine Flat Jacquard Knitting Machine represents a significant leap in mid-scale knitting automation. Its 12gg gauge and 6-feeder system strike an ideal balance between precision and throughput. I recommend it for startups and manufacturers aiming to scale custom knitwear without sacrificing design integrity."

Marco Santini - Fashion Tech Advisor, London Design Hub

"In the era of on-demand manufacturing, machines like this are game-changers. The digital pattern programming and multi-yarn capability align perfectly with sustainable, low-waste production models. For designers looking to prototype or produce limited runs, this machine offers unmatched flexibility."

Posted: 2 days ago

"Switched from manual to digital knitting and couldn’t be happier. Setup took a weekend, now we’re cranking out custom sweaters with intricate jacquard logos. The digital panel is responsive and easy to navigate. A solid investment for serious knitters."

Posted: 1 week ago

"Using the Pro Model for export-grade sweaters. Consistent stitch quality, minimal yarn waste, and fast turnaround. Customer feedback on fabric fineness has been exceptional. Machine feels built to last."

Posted: 3 weeks ago

"Takes time to master, but once you do, the creative possibilities are endless. Love making personalized scarves with colorwork patterns. Only wish the base model had a bit more tutorial support."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.