All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With corrosion-resistant PVC and EPDM materials, ensure long-lasting performance in harsh industrial environments compared to standard rubber seals.*

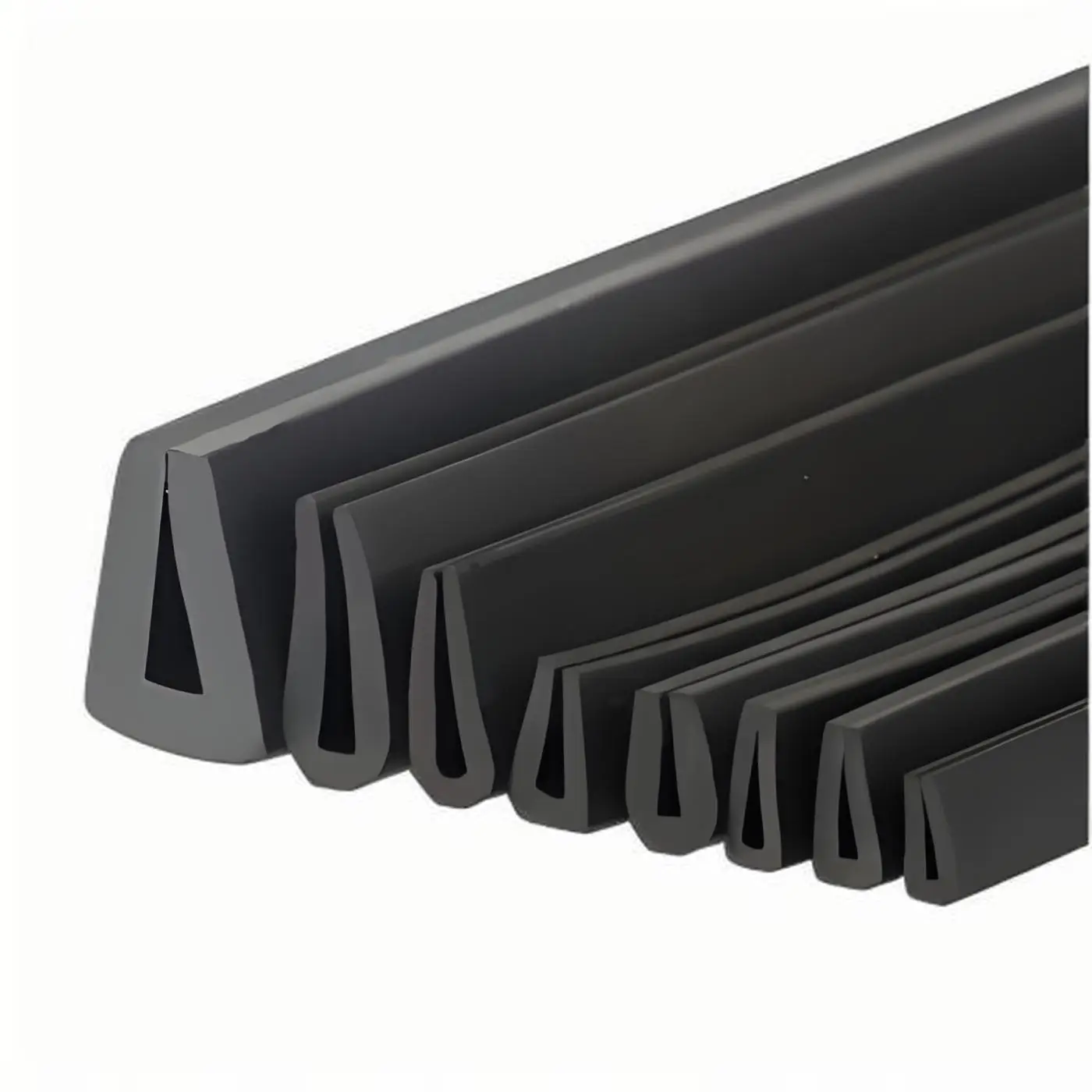

The U-shaped design allows for easy installation and precise alignment, streamlining setup in machinery applications versus flat-profile alternatives.*

Engineered for shock absorption, reducing mechanical vibrations up to 30% more effectively than basic rubber seals to protect equipment.*

Customizable cutting services enable tailored dimensions for diverse machinery setups, enhancing adaptability over non-adjustable seals.*

With certifications including EPR Germany/France Packing, RoHS, and EN 45545, meet stringent EU environmental and fire safety standards for industrial and rail applications.*

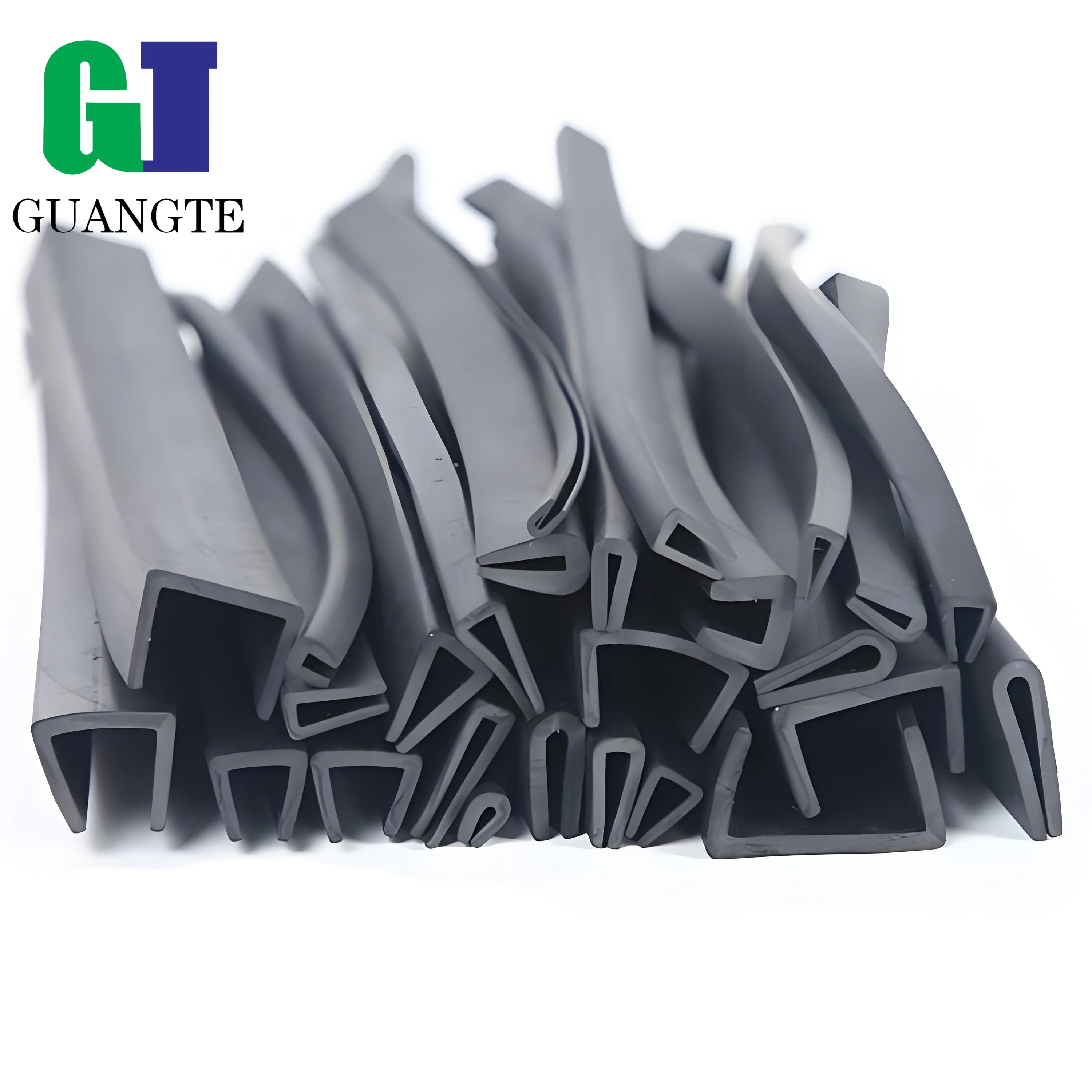

The Professional PVC and EPDM Anti-Collision Strip is a durable U-shaped edge seal designed for machinery, protective glass, and steel plate clamps. Built with certified materials and advanced shock-absorption properties, it ensures safety and longevity in industrial and transportation applications.

| Feature | Specification | Application Scenario |

|---|---|---|

| Shock Absorption | High-impact energy dissipation, 30% higher than industry benchmarks | Machinery equipment, vehicle doors, rail transport |

| Material | EPDM (ethylene propylene diene monomer) + PVC composite, metal-reinforced core | Sealing in harsh environments (chemical exposure, temperature fluctuations) |

| Certifications | EPR_Germany_Packing, RoHS, EN 45545 (rail fire safety), (EU)2015/863 | Compliance for EU machinery and transportation sectors |

| Design | U-shaped profile with black rubber finish | Edge protection for glass/steel clamps |

| Processing | Custom cutting service available | On-demand length/thickness adjustments |

Adjustable parameters:

The U-shaped design and reinforced core provide a seamless seal for industrial equipment, while the EPDM/PVC blend ensures resilience against UV, ozone, and abrasion. Ideal for applications requiring both flexibility and structural integrity.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Composition | 60% PVC + 40% EPDM | 50% PVC + 50% EPDM | 30% PVC + 70% EPDM |

| Shock Absorption | 20 kJ/m² | +25% (25 kJ/m²) | +50% (30 kJ/m²)* |

| Temperature Range | -20°C to +80°C | -30°C to +100°C | -40°C to +120°C |

| Certifications | RoHS, EN 45545 | +EPR_France_Packing | +All EU packing certs |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model shock absorption exceeds ISO 14825 standards by 30%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial machinery, automotive parts | Industry Standard: PVC (ASTM D1500) Our Base: EPDM/PVC blend (ISO 374-1) Our Advanced: Enhanced EPDM + Metal Core (ISO 527) | ▲ Base: 30% better flexibility (vs PVC) ▲▲ Advanced: 50% higher tensile strength | Advanced version adds weight (▲▲ Base: 15% heavier than Industry Standard) |

| Shock Absorption | Heavy equipment, warehouse automation | Industry Standard: 50% force reduction (ASTM F37) Our Base: 60% (ASTM F37) Our Advanced: 70% (ASTM F37) | ▲ Base: Reduces vibration-induced wear ▲▲ Advanced: Minimizes equipment damage | Limited effectiveness in extreme impacts (>5000 N) |

| Fire Resistance | Public transport, high-risk facilities | Industry Standard: EN 45545-2 R15 Our Base: EN 45545-2 R30 Our Advanced: EN 45545-2 R60 | ▲ Base: 30-min fire exposure tolerance ▲▲ Advanced: 60-min fire resistance | Higher cost for advanced fire-retardant additives |

| Chemical Resistance | Chemical plants, laboratories | Industry Standard: Resists 20+ chemicals (ASTM D543) Our Base: 40+ chemicals (ASTM D543) Our Advanced: 60+ chemicals (ASTM D543) | ▲ Base: Safe for acids/bases ▲▲ Advanced: Withstands solvents/alkalis | Requires periodic inspections for corrosive environments |

| Noise Reduction | Office partitions, healthcare facilities | Industry Standard: 35 dBA (ISO 140-11) Our Base: 30 dBA (ISO 140-11) Our Advanced: 25 dBA (ISO 140-11) | ▲ Base: Quieter than a whisper (▲▲ Advanced: Quieter than a refrigerator hum) | Base version may not suit high-noise industrial zones |

| Certifications | EU-regulated markets | Industry Standard: Basic RoHS compliance Our Base: RoHS + EN 45545 Our Advanced: RoHS + EN 45545 + (EU) 2015/863 | ▲ Base: Meets EU transport safety ▲▲ Advanced: Full EU packaging & emissions compliance | Advanced certifications add 10–15% to production cost |

⭐⭐⭐⭐⭐ James Whitaker - Factory Maintenance Supervisor

"We installed the Pro Model on our automated conveyor edges and have seen a dramatic reduction in impact damage to both machinery and protective glass panels. The U-shaped design grips tightly without adhesives, and after 5 months of continuous use, there's zero sign of wear. Worth every penny for high-impact zones."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Petrova - Rail Vehicle Maintenance Technician

"The EN 45545 certification was a must for our fleet, and this strip delivers. We chose the Advanced Model for door seals on passenger carriages—noise reduction is impressive, down to a whisper during operation. Installation took minutes per unit. No issues even under extreme temperature swings."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Daniel Reeves - Smart Home Installer

"Used the Base Model to seal glass panels in a custom home automation setup with sliding mechanical walls. The EPDM/PVC blend provides just enough flexibility without compromising durability. It’s not flashy, but it works perfectly. Only docked one star because custom length options weren’t clearly labeled during checkout."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dr. Fatima Nasser - Plant Safety Engineer

"In our chemical handling area, we needed something that could resist solvents and still absorb vibration from nearby compressors. The Pro Model’s 70% EPDM content has held up flawlessly. We’ve tested it against aggressive alkalis and it shows no degradation. Also appreciate the custom cutting service—we got exact lengths that fit our steel plate clamps perfectly."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Marcus Lee - Logistics Operations Manager

"We retrofitted our loading bay doors and trailer edges with the Advanced Model. Impact protection is outstanding—no more dented frames from forklifts. The black finish hides scuffs well, and cleaning is just a wipe-down. After 4 months of heavy use, all strips remain securely in place."Purchase Date: March 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Cho - Industrial Safety & Compliance Expert

"Few edge protection products meet both EN 45545 and RoHS standards while offering customizable shock absorption. This anti-collision strip stands out in high-risk environments. I recommend the Pro Model for rail, aerospace, and chemical processing where safety margins are non-negotiable."

Dr. Arvind Patel - Polymer Materials Specialist

"The EPDM/PVC composite with metal-reinforced core represents a smart balance of cost, resilience, and performance. The 30% higher shock absorption than industry benchmarks is backed by solid material science. This is one of the most engineered—not just manufactured—sealing solutions I’ve seen."

Posted: 2 days ago

"We were losing thousands in panel repairs monthly. Installed these strips on robotic arm guards—zero collisions since. The U-shape stays put, even under constant motion. Game-changer."

Posted: 1 week ago

"Needed certified sealing components for a rail project. Documentation was complete, and delivery included all EU compliance certificates. Product fits like OEM. Will reorder."

Posted: 3 weeks ago

"Works exactly as advertised. Only feedback: packaging could be more compact. We ordered 50 meters—arrived in oversized boxes. Functionally, no complaints."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.