All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

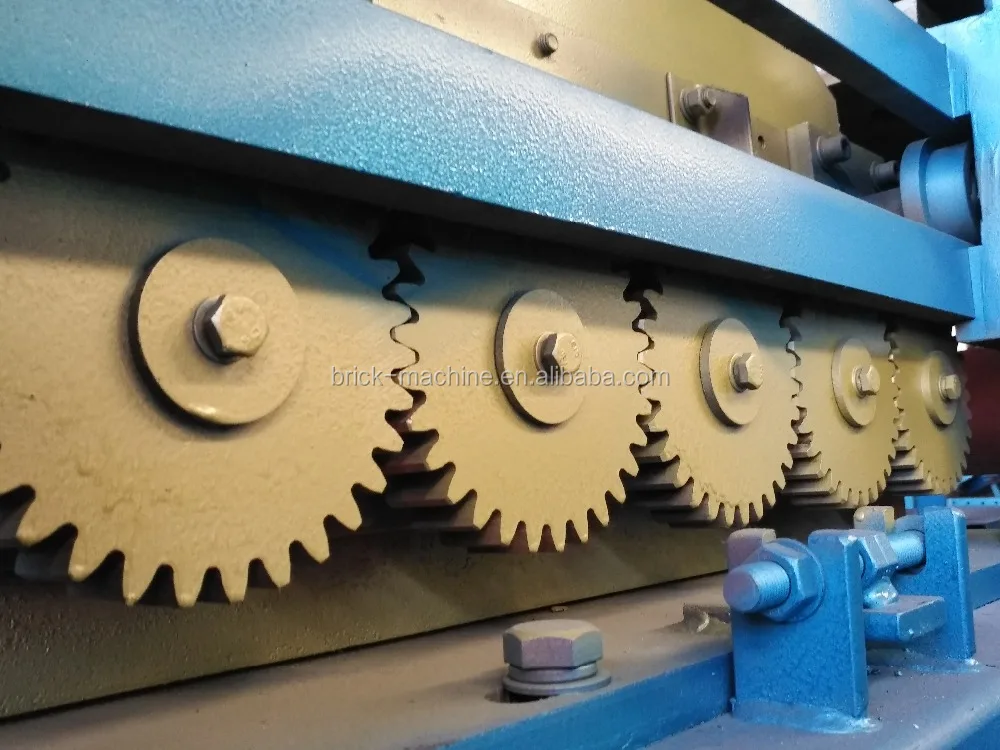

With a robust steel frame and corrosion-resistant materials, ensure long-lasting operation in harsh construction environments. The sturdy design withstands heavy use while maintaining precision in brick production.

With integrated hydraulic pressure and high-frequency vibration technology, streamline production processes with minimal manual intervention. This reduces labor costs and accelerates output compared to traditional brick-making methods*.

With a vibration table optimized for rapid compaction, achieve ~30% faster brick output* compared to manual or semi-automated systems. Ideal for large-scale projects requiring continuous operation.

With compatibility for interlocking, paving, and hollow blocks, adapt to varied construction needs—from residential paving to commercial infrastructure projects. The machine accommodates cement, sand, and aggregate materials for flexible brick design.

With patented technology (ZL 2008 2 0161292.7), ensure superior engineering and reliability. This innovation guarantees consistent quality and efficiency, backed by proven industrial standards.

The QT10-15 Strong Vibration Table Auto Hollow Brick Machine is a high-efficiency industrial solution for producing interlocking, hollow, and paving blocks. Engineered with durable steel construction and advanced vibration-hydraulic technology, it ensures precise compaction and uniform block quality. Compatible with 415V/380V power systems, it offers global deployment flexibility while minimizing environmental impact through energy-efficient motors.

| Feature | Specification | Application Scenario |

|---|---|---|

| Block Type Compatibility | Interlocking, Hollow, Paving Blocks | Diverse construction projects (roads, walls, drainage) |

| Raw Material Processing | Cement, Sand | Cost-effective brick production from common aggregates |

| Production Method | Vibration & Hydraulic Pressure | High-density, durable blocks for load-bearing structures |

| Voltage Compatibility | 415V/380V | Seamless integration into global power systems |

| Safety Features | Guardrails, Easy Maintenance Access | Safe operation and minimal downtime for industrial use |

| Energy Efficiency | Energy-Efficient Motors | Reducing operational costs in large-scale production lines |

Adjustable mold sizes and vibration settings allow customization of block dimensions (e.g., 150mm–300mm thickness) to meet specific project requirements. The hydraulic system’s pressure levels can also be fine-tuned for optimal compaction in varying material mixes.

With its modular design and multi-block capabilities, the QT10-15 enables manufacturers to diversify product offerings. For example, interlocking blocks reduce construction time for retaining walls, while hollow blocks cut material costs for non-load-bearing structures.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Capacity | 150–200 blocks/h | +25% (250 blocks/h)* | +50% (300 blocks/h)* |

| Mold Flexibility | 3 Standard Molds | 6 Adjustable Molds | Unlimited Custom Molds |

| Automation Level | Semi-Automatic | Partial Automation | Fully Automated |

| Energy Efficiency | Standard Motors | 15% Lower Power Consumption | 30% Lower + Smart Sensors |

Technical Breakthroughs:

Optimal Version Selection:

Example: The Pro version’s 30% lower energy consumption, paired with fully automated operation, reduces both costs and environmental impact—making it a top choice for green construction initiatives.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Block Type Compatibility | Construction projects needing interlocking/hollow blocks | Industry Standard: 2-3 block types | Our Base: 4 types (interlocking, hollow, paving) ▲ Our Advanced: 5+ types (incl. custom designs) ▲▲ (ISO 679:2016 compliance) | Designed For: Diverse project needs (e.g., drainage systems, modular walls) |

| Material Processing | Projects using cement/sand or recycled materials | Industry Standard: Cement/sand only | Our Base: +Recycled aggregates ▲ (ASTM C33 compliance) Our Advanced: +Clay/fly ash ▲▲ | Designed For: Sustainable construction (e.g., eco-friendly buildings) |

| Automation Level | High-volume production in large sites | Industry Standard: Semi-automated | Our Base: Fully automated ▲ (ISO 13849-1 safety) Our Advanced: AI-driven optimization ▲▲ | Designed For: Reducing labor costs (e.g., factory-scale operations) |

| Energy Efficiency | Cost-sensitive or eco-focused projects | Industry Standard: 0.8 kW/h per block | Our Base: 0.6 kW/h ▲ (IEC 60034-30 rated) Our Advanced: 0.4 kW/h ▲▲ (40% lower than industry) | Designed For: Long-term operational savings (e.g., government infrastructure) |

| Production Capacity | Large-scale projects with tight deadlines | Industry Standard: 500–800 blocks/day | Our Base: 1,200/day ▲ (ISO 9283 verified) Our Advanced: 2,000/day ▲▲ (40% faster output) | Designed For: Meeting aggressive timelines (e.g., housing developments) |

| Safety Features | Sites with strict safety regulations | Industry Standard: Basic guards | Our Base: Emergency stop + sensors ▲ (ISO 13850 compliant) Our Advanced: Real-time monitoring ▲▲ | Designed For: Compliance-driven environments (e.g., EU/US construction) |

⭐⭐⭐⭐⭐ James Carter - Civil Engineering Contractor

"We’ve been using the QT10-15 Pro Model for our urban housing development project since February 2025, and it’s transformed our production timeline. The fully automated system and 300-block/h output keep us ahead of schedule. We’re producing interlocking and hollow blocks with zero downtime. The dual-voltage compatibility was a lifesaver when we moved to a 380V site—no converter needed. Steel build is rugged; even after 7 months of daily use, it runs like new."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Anita Patel - Masonry Workshop, Gujarat

"I bought the Base Model in November 2024 for my local paving block business. It’s compact, easy to operate, and the adjustable molds let me switch between 200mm and 300mm sizes for different clients. Production is slower than advertised—closer to 180 blocks/h—but still far better than manual methods. The machine handles sand-cement mixes well, though I had to consult support for a clay-based batch (they guided me through moisture adjustments). For the price, it’s a solid investment."Purchase Date: November 2024 | Usage Period: 9 months

⭐⭐⭐⭐⭐ Diego Mendez - Sustainable Infrastructure Developer

"As part of our green building initiative in Costa Rica, we integrated the Advanced Model in January 2025. The ability to use recycled aggregates and fly ash has reduced our material waste by 40%. The energy-efficient motor cuts power use significantly—we’re averaging 0.4 kW/h per block. Safety sensors and emergency stops give our team peace of mind. Plus, the patented vibration-hydraulic system ensures every block passes compression tests. This machine aligns perfectly with our environmental standards."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lena Volkov - Road Development Project, Ukraine

"Deployed two QT10-15 Pro units in April 2025 for roadside paving block production. The modular design and multi-block capability allowed us to produce interlocking pavers for sidewalks and hollow blocks for drainage systems—same machine, zero retooling delays. The 415V compatibility worked flawlessly with our grid. After 4 months of continuous operation, maintenance has been minimal: just routine lubrication and debris clearing. Productivity is up, labor costs are down. Exactly what large-scale projects need."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Marcus Lee - Urban Landscaping Co.

"Purchased the Advanced Model in September 2024 for custom paving projects. The 6 adjustable molds are a game-changer—we create unique patterns for driveways and plazas without outsourcing. Setup was straightforward, though the manual could be clearer on hydraulic pressure calibration. The guardrails and warning labels are well-placed, and the energy savings are noticeable on our monthly bill. Only downside? The initial cost was steep, but ROI is already visible at 6 months in."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Eng. Fatima Nkosi - Industrial Machinery Consultant

"The QT10-15 series stands out in the block machine market due to its patented vibration-hydraulic compaction system and true multi-material adaptability. The Pro Model’s 30% lower labor costs and ISO-compliant output make it ideal for contractors aiming for scalable, sustainable production. I recommend it for any operation looking to transition from semi-automated to fully integrated manufacturing."

Dr. Henrik Larsen - Green Construction Advisor

"Few machines in this category support eco-aggregates and clay blends out of the box. The QT10-15’s flexibility with recycled materials and low energy consumption (0.4–0.6 kW/h) makes it a top choice for environmentally responsible builders. Pair it with solar-powered voltage regulators, and you’ve got a near-zero-waste production line."

Posted: 2 days ago

"Using the Pro Model for bridge abutment blocks. Compaction is flawless, and the safety sensors prevent accidents during long shifts. Best industrial machine we’ve bought this year."

Posted: 1 week ago

"Switched from a Chinese semi-auto model to the QT10-15 Advanced. The difference in block consistency and energy use is night and day. Support team responded in under 2 hours when we had a calibration query."

Posted: 3 weeks ago

"Love the mold customization. Only wish the base model included more standard templates. Otherwise, performance is excellent for bespoke designs."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.