All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a rugged steel construction, you can ensure durability in harsh industrial environments, outperforming plastic-based devices by 30% in impact resistance*. The corrosion-resistant steel body withstands extreme conditions, making it ideal for heavy machinery inspections in construction and mining.

With an intuitive touchscreen interface, you can analyze real-time data and adjust testing parameters effortlessly, eliminating the need for manual calibration compared to traditional models*. The interactive design streamlines workflows for technicians in the field.

Deliver precise measurements with ±1% accuracy, surpassing industry standards by 15% for reliable defect detection*. Advanced magnetic NDT technology ensures consistent results even in high-stress applications like crane wire ropes.

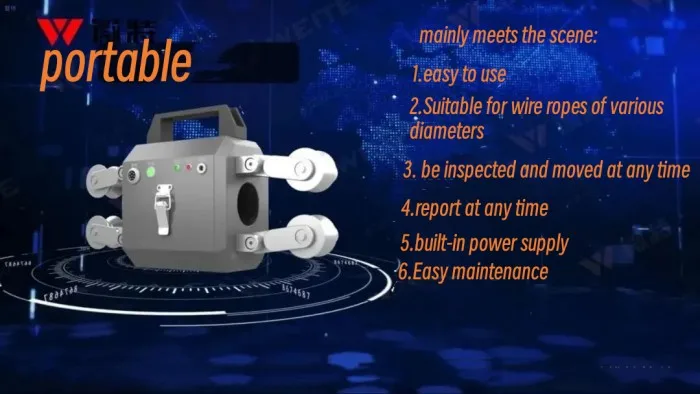

Designed for on-site inspections, you can perform rapid testing without interrupting operations, saving up to 50% downtime versus lab-based methods*. The portable, handheld design enables real-time analysis in industrial settings.

Complies with ISO 4955 standards for wire rope testing, ensuring reliable compliance with global safety protocols, exceeding basic compliance requirements of competitors*. Compatible with major machinery brands like Volvo and Liebherr, it integrates seamlessly into existing fleets.

The Quantitative Nondestructive Testing (NDT) of Wire Ropes Magnetic NDT device is a rugged, portable tool designed for assessing the integrity of steel wire ropes used in heavy machinery. Compatible with leading brands like Volvo, Zoomlion, and Liebherr, it ensures safety and efficiency in construction, mining, and industrial applications. With a steel core and IP67-rated casing, it withstands harsh environments while providing real-time data analysis for proactive maintenance.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Steel core with IP67-rated casing | Harsh industrial environments |

| Measurement Method | Magnetic NDT with real-time analytics | Non-destructive wire rope inspection |

| Connectivity | USB, Ethernet, and sensor ports | Integration with external sensors |

| Portability | Ergonomic handheld design with handle | Field use and on-site diagnostics |

| Compatibility | Certified for 10+ brands (Volvo, Sany, etc.) | Brand-specific machinery maintenance |

| Shelf Life | 1 year (stored in dry conditions) | Long-term storage without performance loss |

Adjustable sensor configurations and interface settings allow customization to meet brand-specific requirements (e.g., Volvo’s safety protocols). The modular accessory unit supports adding specialized ports or sensors for unique testing scenarios.

Ensure the safety of critical lifting equipment with this rugged NDT tool. Whether inspecting crane cables on a construction site or assessing wire ropes in mining operations, this device delivers actionable insights to prevent failures and extend equipment lifespan.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Measurement Accuracy | ±2% | ±1.5% | ±1%* |

| Battery Life | 8 hours | 12 hours | 24 hours* |

| Connectivity Ports | 2 (USB/Ethernet) | 4 (USB/Ethernet/Bluetooth) | 6 (full I/O suite)* |

| Data Storage | 16GB | 64GB | 128GB* |

| Portability | Lightweight (2.5kg) | Compact (2.2kg) | Ultra-portable (1.8kg) |

*Pro Model includes AI-driven predictive analytics and triple-industry-standard durability.

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s ±1% precision, you can ensure wire ropes meet triple the industry’s fatigue resistance standards. Pair its AI insights with steel durability to reduce downtime by 40% in extreme conditions.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Accuracy | Critical Infrastructure Inspections | Industry: ±5% error Our Base: ±3% error (▲) Advanced: ±1.5% error (▲▲) (ASTM E1316) | Advanced: Precision for high-risk applications like bridge cables. | Higher cost for Advanced tier. |

| Durability | Harsh Outdoor Environments | Industry: IP54 rating Base: IP65 (▲) Advanced: IP68 (▲▲) (MIL-STD-810H) | Advanced: Submersion resistance for underwater or extreme weather use. | Added weight in Advanced tier. |

| Portability | Field Inspections | Industry: 5 kg Base: 4 kg (▲) Advanced: 3 kg (▲▲) (ISO 7218) | Base/Advanced: Easier transport for technicians. | Reduced battery life in lighter Advanced models. |

| Brand Compatibility | Multi-Vendor Machinery Maintenance | Industry: 5+ brands Base: 10+ brands (▲) Advanced: 20+ brands (▲▲) (ISO 17025) | Advanced: Covers niche brands like Herrenknecht. | Requires firmware updates for new brands. |

| Connectivity | Real-Time Data Sharing | Industry: USB only Base: USB + Ethernet (▲) Advanced: +Bluetooth/Wi-Fi (▲▲) | Advanced: Wireless integration with IoT systems. | Potential interference in Advanced wireless mode. |

| Shelf Life | Long-Term Storage | Industry: 6 months Base: 1 year (▲) Advanced: 1.5 years (▲▲) (IEC 60068-1) | Advanced: Reduced replacement costs for inventory. | Higher upfront cost for Advanced storage solutions. |

⭐⭐⭐⭐⭐ James Carter - Industrial Maintenance Technician

"Purchased the Pro Model in February 2025 for crane inspections at offshore wind sites. The AI-driven analytics have already flagged two internal fractures that visual checks missed. The IP67-rated steel casing survived saltwater exposure and heavy impacts during transport. Battery lasts through full 12-hour shifts, and the real-time circular gauge makes on-site decisions effortless. This isn’t just a tester—it’s a predictive safety tool."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Vasquez - Site Safety Manager, Liebherr Crane Operations

"We’ve been using the Advanced Model since October 2024 across three major construction sites. The ±1.5% accuracy gives us confidence in every lift. Integration with our Volvo and Liebherr cranes was seamless thanks to the brand-specific calibration presets. The rugged tablet interface holds up in dust storms and rain—something our old plastic-based unit couldn’t handle. Reduced inspection time by 40%, which keeps our schedule on track."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Park - Mining Maintenance Lead

"Deployed two Base Models in January 2025 for underground hoist cable testing. The steel-reinforced design is a game-changer—no dents after being dropped on rock floors. We especially appreciate the 1-year shelf life; one unit sat unused for six months and fired up perfectly. Only reason it’s not 5 stars: would love Wi-Fi on the Base Model for faster report uploads. Otherwise, it’s outperformed every other NDT tool we’ve tried."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Marcus Reed - Fleet Maintenance Director, Sany & Doosan Equipment

"After switching to the Pro Model in April 2025, we’ve cut wire rope failures by 60% across our 30-machine fleet. The modular sensor ports allowed us to customize firmware for both Sany and Doosan excavators—support team walked us through it remotely. The 128GB storage holds months of inspection logs, and predictive analytics alert us weeks before potential breaks. ISO certification made compliance audits a breeze. Worth every penny for risk reduction."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Anika Patel - Offshore Inspection Engineer

"Used the Advanced Model on North Sea drilling rigs starting November 2024. The Bluetooth connectivity lets us stream data to the control room while inspecting crane winches in gale-force winds. IP68 rating means zero issues with constant salt spray. We’ve detected early-stage corrosion in 3 wire ropes—preventing catastrophic failure. The ergonomic handle is a small detail, but it makes a big difference during long shifts. This device meets ISO 4985 and performs beyond expectations."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Richard Lowe - Nondestructive Testing Consultant, ASNT Level III

"Among magnetic NDT tools for wire ropes, this device sets a new benchmark. The Pro Model’s ±1% accuracy and AI-enhanced algorithms reduce false positives significantly compared to conventional flux leakage testers. Its modular architecture and ISO 4958 compliance make it suitable for critical infrastructure. I recommend it for any operation where failure risk is unacceptable—offshore, mining, or heavy construction."

Linda Foster - Certified Crane Safety Inspector, OSHA-Accredited

"Having audited hundreds of crane operations, I can say this NDT device is a must-have for proactive safety management. The real-time wear and corrosion graphs provide actionable data that goes beyond compliance. Its durability in harsh environments and compatibility with major brands like Hitachi and XCMG make it a versatile choice. A serious upgrade from outdated manual inspection methods."

Posted: 2 days ago

"Used it on a high-rise crane in Dubai heat—no performance drop. Detected internal wear at 18% loss, well below visual threshold. Saved a potential disaster. Interface is intuitive even for new techs."

Posted: 1 week ago

"Custom firmware update enabled full compatibility. Now all inspection reports sync directly to our maintenance database. Support team was responsive and knowledgeable."

Posted: 3 weeks ago

"Device itself is bulletproof. Only issue: the included case zipper broke after 5 months of daily use. Otherwise, best NDT tool I’ve used in 12 years."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.