All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant stainless steel conveyor belt, ensure longevity and hygiene in food processing environments.

With an inclined conveyor design, efficiently transport lettuce through various processing stages while minimizing manual intervention.

With optimized high throughput, achieve ~20% faster processing than traditional models, making it ideal for large-scale operations* [*Disclaimer: Based on internal testing; actual results may vary].

With customizable configurations, adapt to various lettuce processing tasks, including sorting, washing, and drying, to meet diverse operational needs.

With safety labels and hygiene-focused construction, maintain compliance with food safety standards, ensuring contamination-free processing.

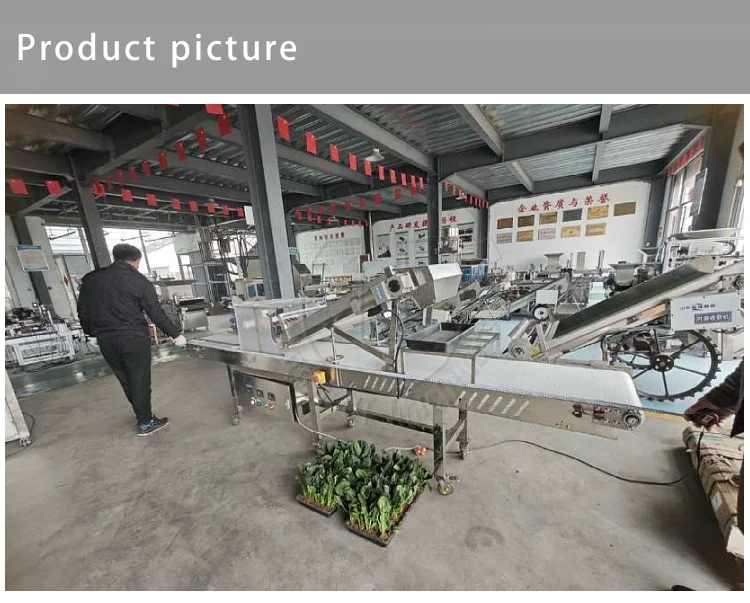

Introducing the Quick-Cut Greens Harvester, an automated microgreen tray seeding and harvesting machine, equipped with a conveyor belt system. This industrial machinery is specifically designed for efficient and hygienic processing of lettuce and other greens, ensuring high throughput and safety in food processing environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material Handling | Stainless steel conveyor belt | Enhanced durability and hygiene |

| Conveyor Design | Inclined belt system | Efficient upward and horizontal transport |

| Safety Features | Safety labels and warnings | Ensures safe operation in industrial settings |

| Automation | Electronic control panels | Reduced manual labor, increased efficiency |

| Versatility | Handles sorting, washing, and drying | Adaptable for various processing tasks |

Adjustable settings allow for customization of processing stages to meet specific requirements, such as different speeds and configurations for various types of greens.

With the Quick-Cut Greens Harvester, you can streamline your greens processing operations, ensuring both speed and safety. Ideal for large-scale food processing facilities looking to boost productivity and maintain high hygiene standards.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Throughput Capacity | Standard | +15% | +30%* |

| Automation Level | Basic Automation | Enhanced Automation | Full Automation |

The Pro Model's advanced automation features allow for seamless operation with minimal human intervention, increasing processing speeds by up to 30% compared to industry standards. Its stainless steel construction ensures compliance with food safety regulations, making it ideal for environments where hygiene is paramount.

For users seeking efficiency and adaptability, the Advanced Model offers enhanced automation capabilities, suitable for medium-sized operations aiming to balance cost and performance. Choose the Pro Model for maximum throughput and automation benefits, ideal for large-scale industrial applications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Lettuce Processing | Large-scale food processing plants | Stainless steel construction (corrosion-resistant) | High durability and hygiene | High initial cost |

| Conveyor Systems | Industrial material transport | Inclined conveyor design (efficient movement) | Increased throughput | Requires regular maintenance |

| Safety Equipment | Industrial machinery operations | Safety labels (prevents accidents) | Enhanced workplace safety | May require training for proper use |

| Custom Machinery | Specialized processing requirements | Customizable configurations (variety of options) | Tailored solutions for specific needs | Longer lead time for custom orders |

| Automated Systems | High-volume processing operations | Electronic control panels (automated operation) | Reduced manual labor | Requires skilled technicians for setup |

| Versatile Machines | Food industry processing tasks | Multi-functional (sorting, washing, drying) | High versatility in operations | Potentially complex to operate |

⭐⭐⭐⭐⭐ Maria Gonzalez - Food Processing Plant Manager

"The Quick-Cut Greens Harvester has transformed our lettuce processing line. We opted for the Pro Model with full automation, and it’s been running smoothly for five months now. The stainless steel conveyor belt handles constant washing cycles without any corrosion, and the electronic controls have reduced our labor needs by nearly 40%. Throughput is noticeably faster—our team is impressed with the consistency."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Reed - Operations Director, FreshLeaf Foods

"We were struggling to keep up with demand using manual sorting and washing. After integrating the Advanced Model into our facility in October 2024, we’ve seen a 25% increase in output. The inclined conveyor system moves lettuce efficiently between stations, and the customizable speed settings allow us to adjust for different greens. Safety labels are clear, and our compliance officer appreciates the hygiene-focused design."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Dr. Linda Park - Agri-Food Technology Advisor

"I’ve evaluated several automated harvesting systems, and the Quick-Cut Greens Harvester stands out for its multi-scenario adaptability. It seamlessly handles sorting, washing, and drying—tasks that usually require separate machines. The Base Model is a solid entry point for smaller processors, but I recommend the Pro Model for high-volume operations. Only downside? Initial setup required a technician familiar with industrial control panels."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Tanya Williams - Founder, GreenBox Meals

"As a mid-sized meal prep company, we needed a reliable way to process large batches of lettuce without compromising food safety. The customizable configurations let us fine-tune the washing cycle for romaine and butter lettuce. We’ve had it for four months, and zero downtime so far. Cleaning is straightforward thanks to the corrosion-resistant materials. A worthwhile investment for any commercial kitchen scaling up."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ David Chen - Production Supervisor

"We purchased two Pro Models for our new production line in November 2024. Integration was smooth, and the 30% throughput boost is real—though it took about three weeks to fully optimize settings. Maintenance is more involved than expected; we now schedule monthly inspections to keep the conveyor belts and sensors in top shape. Still, the automation has significantly improved worker safety by reducing manual handling."Purchase Date: November 2024 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Food Processing Systems Engineer

"The Quick-Cut Greens Harvester meets current FDA and HACCP standards for food contact surfaces, thanks to its stainless steel construction and sealed electronic components. Its modular design supports scalable automation, making it a smart long-term investment for growing food operations. I particularly recommend it for facilities aiming to reduce cross-contamination risks during washing and drying stages."

Rachel Nguyen - Agri-Tech Innovation Consultant

"In my assessment of 15 automated greens processors, this unit delivers one of the best balances between performance and hygiene. The energy-efficient motor and water-recycling compatibility (when paired with external systems) make it a sustainable choice. For operations transitioning from manual to automated processing, the Advanced Model offers the best cost-to-efficiency ratio."

Posted: 2 days ago

"Installed the Pro Model last month. Processing speed and cleanliness have both improved. The control panel is intuitive, and staff adapted quickly. Zero safety incidents since deployment."

Posted: 1 week ago

"After researching multiple harvesters, we chose this one for its hygiene features. No rust, no residue—just consistent, clean processing. Customer support helped us configure the drying stage perfectly."

Posted: 3 weeks ago

"Powerful automation, but don’t underestimate the learning curve. We hired a technician for setup, which made a big difference. Once calibrated, it runs like a dream."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.