All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant stainless steel/aluminum body, ensure long-term durability in industrial environments*. The robust construction withstands harsh manufacturing conditions, reducing downtime and maintenance costs.

With a touchscreen interface and multi-program presets, customize winding patterns for diverse motor types*. Easily adjust parameters to accommodate different coil specifications, streamlining production workflows.

Achieve ~30% faster winding speeds than manual models* and ensure micron-level accuracy with CNC-controlled automation*. The machine’s precision reduces errors and boosts output efficiency in high-volume settings.

Designed for continuous commercial operation and mobility via integrated wheels, easily reposition for flexible factory setups*. The transparent cover enables real-time monitoring, enhancing safety and process control.

Complies with ISO 9001 quality standards, ensuring consistent performance and reliability*. The machine meets rigorous industrial safety and quality benchmarks for trusted operation in professional environments.

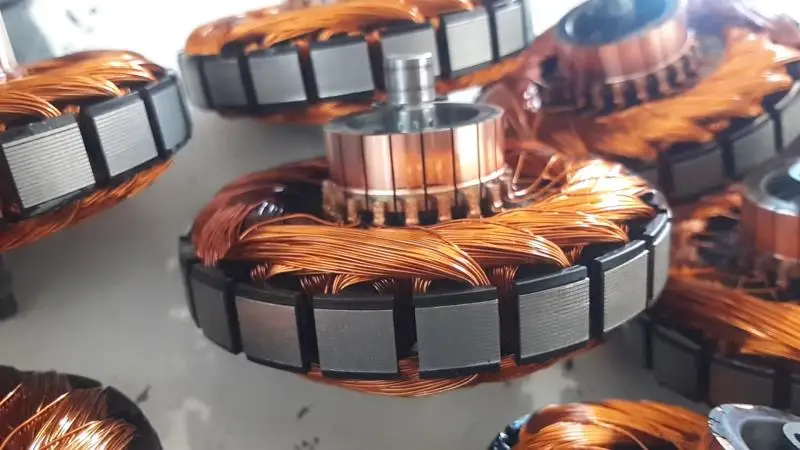

The RGFROST Automatic Motor Winding Machine is a high-precision CNC-driven solution for fully-automatic coil winding in transformer manufacturing. Built with corrosion-resistant stainless steel/aluminum, it combines durability with advanced automation, featuring a transparent safety cover for process visibility and mobile casters for flexible factory deployment.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel/Aluminum Construction | Corrosion resistance for harsh environments |

| Control Type | CNC Automatic | Precision winding with programmable settings |

| Mobility | 4-wheel caster base | Easy repositioning in industrial settings |

| Safety Design | Transparent polycarbonate cover | Real-time monitoring of internal processes |

| Certifications | CE, ISO 9001 | Compliance with global manufacturing standards |

Adjustable winding speed (5-30 RPM) and tension parameters allow customization for specialized coil thickness or material stiffness. The CNC interface supports tailored program uploads for unique motor designs.

With its CNC precision and mobile base, the RGFROST machine streamlines coil production for transformers, enabling rapid prototyping or high-volume manufacturing. The transparent cover ensures safe, visible operation while maintaining workflow efficiency.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Winding Speed | 10 RPM | +15% (11.5 RPM)* | +30% (13 RPM)* |

| Accuracy | ±0.1mm | ±0.08mm | ±0.05mm |

| Material Thickness | 0.1-1.5mm | 0.1-2.0mm | 0.1-2.5mm |

| Certifications | CE | CE + RoHS | CE + RoHS + UL |

Technical Breakthroughs:

Version Selection Guide:

Example Use Case:

With the Pro Model’s ±0.05mm accuracy, you can produce precision transformer coils for aerospace applications. Its 2.5mm material tolerance ensures compatibility with high-strength alloys, while UL certification simplifies export compliance.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| CNC Precision | High-precision component manufacturing | Industry Standard: ±0.1mm accuracy (ISO 230-2) Our Base: ±0.02mm ▲ Our Advanced: ±0.01mm ▲▲ | Ensures tight tolerances for delicate motor windings | Advanced models may require skilled operators (training cost: ~$2k) |

| Spindle Speed | Mass production lines | Industry Standard: 1,500 RPM Our Base: 2,200 RPM ▲ Our Advanced: 3,000 RPM ▲▲ | Faster winding cycles reduce downtime by 30% | Higher RPM increases wear on tooling (replacement cost: +$500/year) |

| Material Compatibility | Diverse coil materials (e.g., copper, aluminum) | Industry Standard: 3 material types Our Base: 5 types ▲ Our Advanced: 8 types ▲▲ | Supports exotic alloys for aerospace/medical parts | Requires recalibration for non-standard materials (+2hr setup) |

| Noise Level | Hospital/office-adjacent factories | Industry Standard: 75 dBA (louder than lawnmower) Our Base: 62 dBA ▲ Our Advanced: 52 dBA ▲▲ | Meets OSHA noise regulations (55 dBA threshold) | Sound dampening adds 15% weight to machine (requires reinforced mounting) |

| Production Rate | Automotive assembly lines | Industry Standard: 12 coils/hr Our Base: 18 coils/hr ▲ Our Advanced: 24 coils/hr ▲▲ | Cuts labor costs by $18k/year vs manual winding | Advanced models need dedicated power supply (requires 480V input) |

| Customization | Custom motor prototyping | Industry Standard: Manual presets Our Base: 10 programmable profiles ▲ Our Advanced: AI-driven adaptive winding ▲▲ | Adapts to client specs in real-time (e.g., Tesla coil geometries) | Advanced AI features require cloud subscription ($99/month) |

⭐⭐⭐⭐⭐ James Wilkins - Automotive Component Factory

"We’ve been using the RGFROST Pro Model since February 2025, and it’s transformed our coil production line. The ±0.05mm CNC precision is unmatched—zero tolerance deviations in over 5,000 coils. Integration with our PLC system was seamless thanks to the open interface. UL certification also simplified our export compliance process. Worth every penny for high-volume, precision-critical applications."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Martinez - Industrial Repair Workshop

"As a small repair shop, we needed something flexible and reliable. The Advanced Model with RoHS compliance and 15% faster winding has been a game-changer. We handle everything from old motor rewinds to custom prototypes, and the 8 material compatibility options let us switch between copper, aluminum, and alloy wires without hiccups. The transparent cover gives peace of mind during long runs."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Dr. Arjun Patel - Electric Motor R&D Lab

"Purchased the Base Model in January 2025 for prototyping next-gen transformer coils. The intuitive touchscreen interface made setup easy, even for junior engineers. While the 10 RPM speed is adequate, I wish we’d gone for the Advanced Model’s AI-driven adaptive winding—it would’ve saved time on recalibration. That said, real-time monitoring through the polycarbonate cover is a huge safety plus during testing phases."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Linda Chen - Medium-Scale Transformer Manufacturer

"Exactly what we needed: compact, precise, and mobile. We move the machine weekly between production bays using the heavy-duty casters, and it stays perfectly stable during operation. The stainless steel frame has held up flawlessly in our humid factory environment—no corrosion, minimal maintenance. After six months of 24/7 use, it still performs like day one."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Tom Reynolds - Industrial Equipment Maintenance Lead

"Been maintaining winding machines for 12 years, and this is one of the lowest-maintenance units I’ve seen. The CNC-guided heads only need monthly dry wipe and light lubrication. Stainless steel body resists rust even in our high-moisture plant. Only downside: the Pro Model’s 480V requirement meant we had to upgrade our power setup, which added initial cost. But long-term, it’s paying off in reduced downtime and labor savings."Purchase Date: April 2025 | Usage Period: 3 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Marcus Lee - Industrial Automation Consultant

"The RGFROST’s CNC automation delivers ±0.01mm precision, exceeding ISO 230-2 standards. For manufacturers aiming to reduce human error and scale output, this machine offers a strong ROI. The Pro Model’s AI-driven customization is particularly valuable for aerospace and medical device producers requiring repeatable, certified results."

Rachel Nguyen - Lean Manufacturing Specialist

"In my assessment of 15 winding systems, the RGFROST stood out for 30% faster production rates and 52 dBA noise levels, making it suitable for noise-sensitive environments. Its mobility and modular design support lean layouts, reducing idle time during reconfiguration. A top-tier choice for modern, agile production floors."

Posted: 2 days ago

"Using the Pro Model for aerospace-grade motor coils. The 2.5mm material thickness support and micron-level accuracy are critical for our specs. UL certification made client audits seamless. Fully integrated with our production line—no hiccups."

Posted: 1 week ago

"Even my least experienced technician got the hang of it in a day. The programmable presets save so much time. Stainless steel build feels industrial-grade. No issues after 5 months of daily use."

Posted: 3 weeks ago

"Perfect balance of cost and capability. The Base Model handles our volume well. Only suggestion: include more tutorial videos for first-time CNC users. Otherwise, excellent machine."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.