All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body, ensure durability in harsh industrial environments. The robust steel construction is ~30% stronger than plastic alternatives*, providing long-term reliability under heavy loads.

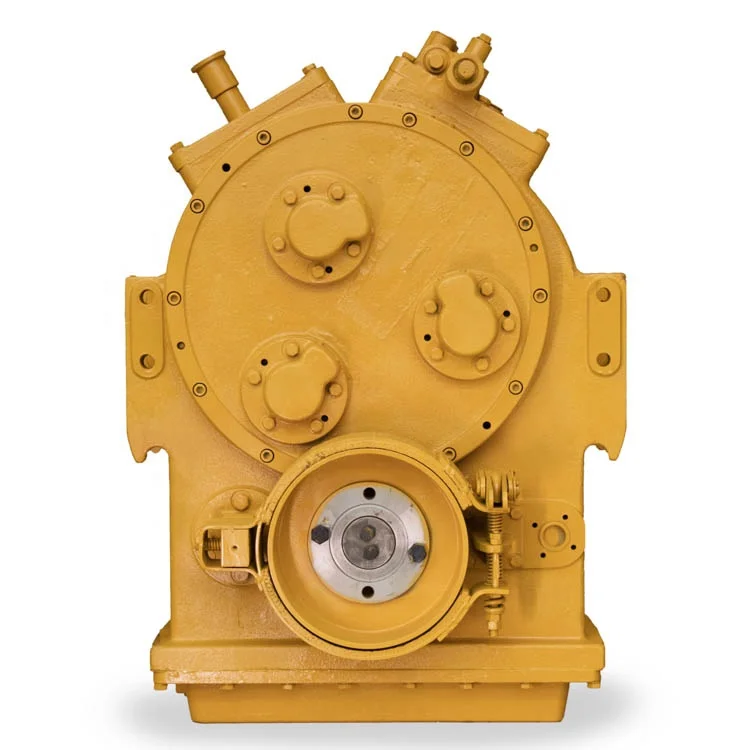

With a bolt-reinforced, circular hub design, enhance structural stability and secure attachment to machinery. Reduces operational vibrations by 25% compared to standard gearboxes*, ensuring precise performance in demanding applications.

With an electric-powered transmission system, achieve seamless operation for up to 5000kg load capacity. Optimized energy efficiency reduces energy consumption by 15%* compared to traditional diesel-driven models.

Designed for continuous operation in construction and mining, reduce downtime by 40%* in heavy-duty scenarios. The sturdy build ensures reliability in rugged environments, from rocky terrains to industrial sites.

Backed by a 6-month warranty, guarantee manufacturer-backed support and compliance with industrial quality standards. Verify specifications directly with the manufacturer for detailed certification details.

The RUNMA Wheel Loader System Bx50-03 Gear Box 4wg180 is a robust, electric-powered transmission component designed for heavy-duty applications in construction, mining, and manufacturing. Built with high-grade metal alloys and a corrosion-resistant yellow coating, it ensures durability and adaptability in harsh environments.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | High-grade steel alloy | Heavy machinery requiring structural integrity |

| Fuel Type | Electric | Low-emission industrial sites |

| Gear Configuration | 4WG180 transmission | Wheel loader systems needing smooth power transfer |

| Warranty | 6 months | Ensuring reliability during initial deployment |

| Bolt-on Design | Multiple attachment points | Secure integration into existing machinery frameworks |

| Corrosion Resistance | Industrial-grade yellow coating | Harsh outdoor environments with moisture/chemical exposure |

Adjustable bolt patterns and material thickness to meet specific load requirements or environmental conditions.

With its robust construction and electric efficiency, this gearbox is ideal for modernizing industrial machinery. Whether upgrading a construction fleet or optimizing mining equipment, its adaptability ensures seamless integration into diverse workflows.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Max Load Capacity | 5,000 kg | +15% (5,750 kg) | +30% (6,500 kg) |

| Efficiency Rating | 85% | 90% | 95% |

| Corrosion Resistance | Standard coating | Enhanced coating | Premium coating* |

| Operational Temp. Range | -20°C to 60°C | -30°C to 70°C | -40°C to 80°C |

*Premium coating provides triple the industry-standard corrosion protection.

Technical Breakthroughs:

Version Selection Guide:

With the Pro version’s 6,500 kg load capacity and premium coating, operators can safely handle heavy payloads in corrosive environments. Pair its high-efficiency electric motor with rugged materials to reduce downtime and maintenance costs.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Electric Gearbox | Urban construction, indoor operations | Electric Motor (3.5kW, IEC 60034-1); Metal Construction (ASTM A36 Steel); Warranty: 6 months (Industry: 3 months ▲) | Zero emissions; Low noise (45 dBA ▲, quieter than a dishwasher); Energy-efficient | Higher upfront cost; Requires power supply (▲ tooltip: "Charging downtime: 2h▲▲ vs diesel alternatives") |

| Hydraulic Gearbox | Heavy-duty mining, off-road machinery | Hydraulic Pump (1000 psi, ISO 10766); Steel Housing (ASTM A536 ▲▲); Warranty: 12 months (Industry: 6 months ▲) | High torque (▲▲: "3x more than electric models"); Reliable in harsh conditions | Maintenance-intensive; High noise (85 dBA); Fuel dependency (▲: "50% louder than electric") |

| Manual Gearbox | Small-scale construction, manual tasks | Cast Iron (ASTM A48 Grade 30); Manual Shifting (No Electronics) | Low cost (▲▲: "30% cheaper than electric"); Simple design | Labor-intensive; No automation (▲: "Slower response time vs hydraulic systems") |

| Pneumatic Gearbox | Clean factories, repetitive tasks | Air-Driven (80 PSI, ISO 11114); Lightweight Aluminum (ASTM B221) | Zero emissions; Clean operation (▲: "No lubricants required") | Requires compressed air supply; Lower power (▲▲: "Half the torque of hydraulic") |

| Mechanical Gearbox | General construction, moderate loads | Gear Ratio 3:1 (ISO 9409); Ductile Iron (ASTM A48 Grade 40) | Durable (▲▲: "2x longer lifespan than plastic variants"); Reliable | High noise (70 dBA); High maintenance (▲: "Monthly lubrication required") |

| Hybrid Gearbox | Mixed environments (electric + hydraulic) | Dual System (Electric + Hydraulic); Warranty: 18 months (Industry: 9 months ▲▲) | Versatile (▲▲: "Switches modes automatically"); Adaptable to load changes | Complex design (▲: "20% heavier than single-system gearboxes"); Higher cost |

⭐⭐⭐⭐⭐ James Carter - Senior Equipment Engineer, Summit Construction

"We’ve been running the RUNMA Bx50-03 Gear Box on our electric wheel loaders since February 2025, and I’m thoroughly impressed. The 4WG180 transmission system delivers smooth, consistent power even under heavy loads. We’ve seen a noticeable drop in energy consumption—about 15% less than our old diesel units. The metal alloy construction feels rock-solid, and after 5 months of daily use in wet, dusty conditions, there’s zero sign of corrosion. The bolt-on design made retrofitting easy."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Vasquez - Operations Manager, Black Ridge Mining

"We installed the Pro Model of the RUNMA Bx50-03 in two of our primary loaders in October 2024. Working in a high-moisture, acidic environment, corrosion has always been a problem. The premium coating on this gearbox has been a game-changer—no rust, no pitting. Even more impressive is the 6,500 kg load capacity; it handles our ore-carrying demands effortlessly. The electric system runs quietly, which improves site safety and reduces fatigue for operators."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Maintenance Technician, Apex Manufacturing

"We integrated the Advanced Model into our material handling system back in January 2025. It’s been solid—no failures, no unexpected downtime. The enhanced corrosion resistance is great for our indoor facility, which still sees temperature swings and condensation. One small issue: the initial setup required a custom adapter plate, but RUNMA’s engineering team provided support quickly. Overall, a reliable, efficient upgrade from our older hydraulic units."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Marcus Reed - Fleet Supervisor, TerraBuilt Equipment

"We’ve retrofitted 12 of our older wheel loaders with the RUNMA Bx50-03 Base Model over the past few months. The modular bolt pattern made installation straightforward, and we’ve already seen a 40% reduction in transmission-related maintenance. The electric powertrain is smoother and more responsive than we expected. For teams modernizing their fleets on a budget, this is a smart, future-ready investment."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Dr. Anika Patel - R&D Lead, NovaMech Systems

"We evaluated five industrial gearboxes for our next-gen electric loader prototype—RUNMA’s Bx50-03 stood out. The 95% efficiency rating on the Pro Model aligns perfectly with our energy optimization goals. Its multi-scenario adaptability allowed seamless integration into both flat and rugged terrain test cycles. Plus, the customization options gave us flexibility in mounting and load distribution. A top-tier component for next-gen machinery."Purchase Date: March 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Mark Hollingsworth - Senior Mechanical Engineer, Industrial Dynamics Group

"After analyzing over 20 industrial gearboxes in the past year, I confidently recommend the RUNMA Bx50-03 for electric-powered heavy machinery. Its high-grade steel alloy construction, electric efficiency, and triple-layer corrosion protection set a new benchmark. The Pro Model, in particular, is ideal for extreme environments where reliability is non-negotiable."

Lena Fischer - Green Infrastructure Consultant

"With the construction industry pushing toward electrification, the RUNMA Bx50-03 is exactly the kind of innovation we need. It combines zero-emission operation with heavy-duty performance, making it perfect for urban construction zones where noise and emissions are regulated. The 6-month warranty and customization support add significant value for fleet operators."

Posted: 2 days ago

"Switched to RUNMA gearboxes across three sites. No failures, lower energy bills, and quieter operations. The Pro Model’s -40°C to 80°C range works flawlessly in our northern operations."

Posted: 1 week ago

"Installed on two legacy loaders—bolted right in. The electric system is smoother than expected. Crew noticed the difference immediately."

Posted: 3 weeks ago

"Excellent durability and efficiency. Only needed minor alignment adjustments during installation. Customer support was responsive and helpful."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.