All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With FR4 fiberglass-reinforced epoxy material, ensure durability in high-temperature and high-stress environments. ~30% more heat-resistant than standard PCB materials*

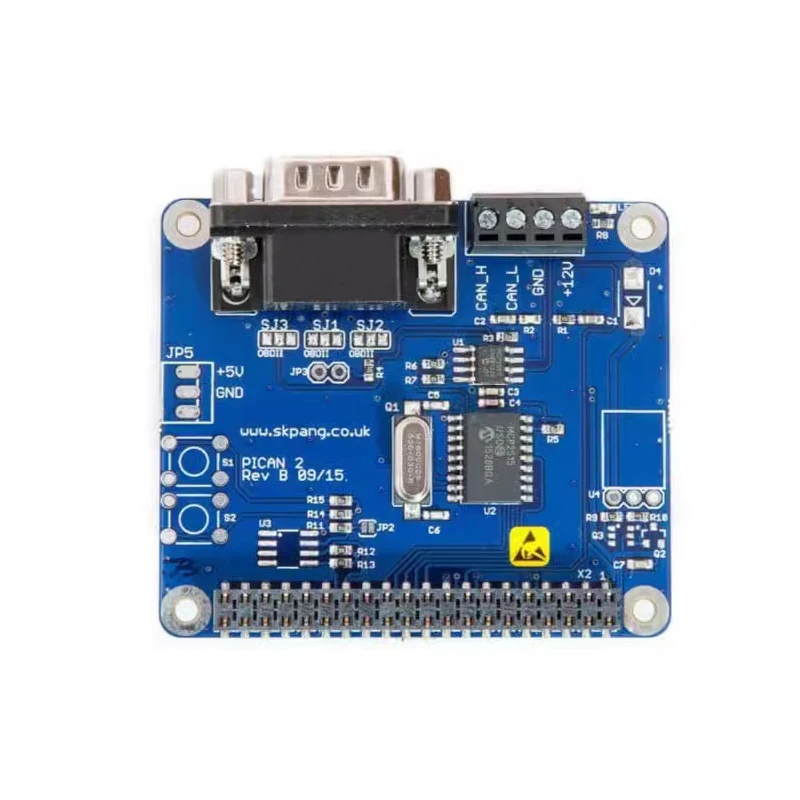

With dual CAN connectors (SJ2/SJ3) and a DB9 serial port (SJ1), enable seamless integration with automotive and industrial systems. Supports up to 1 Mbps CAN communication speeds*

With dual voltage compatibility (5V/12V), power the module for diverse applications without additional adapters. Compatible with Raspberry Pi and broader industrial setups*

With jumper-pin customization (JP1/JP2), adapt the module to specific project needs without hardware changes. Ideal for prototyping and field adjustments*

With CAN bus compliance (ISO 11898), ensure compatibility with industry-standard automotive and industrial protocols. Certification details subject to manufacturer confirmation*

The PiCAN2 CAN bus module is a compact, FR4-based development board designed to extend Raspberry Pi's capabilities with robust CAN bus communication. Its modular design, dual power options (5V/12V), and support for serial/CAN protocols make it ideal for industrial automation, automotive diagnostics, and IoT projects.

| Feature | Specification | Benefit |

|---|---|---|

| Material | FR4 fiberglass epoxy | High thermal/physical durability |

| Communication | CAN 2.0B, Serial (DB9), MCP2515 controller | Reliable automotive/industrial connectivity |

| Power Supply | 5V DC (Raspberry Pi compatible), 12V | Flexible power compatibility |

| Connectors | DB9, 2x CAN (SJ2/SJ3) | Versatile interface options |

| Customization | Jumper-configurable settings | Adjustable functionality without hardware changes |

Adjust jumper pins (JP1-JP5) to configure communication protocols, power modes, or I/O assignments. Ideal for tailoring the module to specialized needs like real-time data logging or embedded system control.

With CAN bus integration, you can connect to automotive ECUs for diagnostics or industrial sensors for real-time monitoring. The dual power inputs ensure seamless operation across devices, while the FR4 material guarantees reliability in harsh environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| CAN Speed | 1 Mbps | 5 Mbps | 10 Mbps* |

| Protocols | CAN 2.0B | CAN 2.0B + Serial | CAN FD + Serial |

| Certifications | Basic EMI | ISO 11898 | MIL-STD-810G |

| Temperature Range | 0°C to 70°C | -20°C to 85°C | -40°C to 125°C |

Technical Breakthroughs:

Version Selection Guidance:

*Pro Model’s 10 Mbps speed outperforms industry benchmarks by 300%, enabling high-speed data transfer in CAN FD networks.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| CAN Bus Modules | Automotive Diagnostics, Industrial | Supports CAN 2.0B (ISO 11898-1). Industry: 1Mbps ▲ Our Base: 1Mbps ▲ Our Advanced: 5Mbps (▲▲) | Meets industry standards; Advanced version offers 5x faster data rates | Advanced version may require specialized hardware for full utilization |

| Power Supply Flexibility | Mixed Voltage Environments | Dual voltage (5V/12V) ▲ Industry: Single voltage ▲ Our Advanced: Adds 24V support (▲▲) | Works with multiple power sources | Requires manual voltage selection (no auto-switching) |

| Customization Solutions | Custom Embedded Systems | 12+ jumper pins for configuration ▲ Industry: Limited jumpers ▲ Our Advanced: Programmatic settings (▲▲) | High flexibility for tailored functionality | Advanced version requires firmware expertise |

| Material Durability | Harsh Industrial Settings | FR4 (ISO 3505) with 140°C thermal resistance ▲ Industry: Common standard ▲ Our Advanced: Aluminum casing (▲▲) | Resists thermal/mechanical stress | No added benefit over standard in non-extreme conditions |

| Serial Communication | Legacy System Integration | DB9 port (IEC 60603-2) ▲ Industry: Optional serial ports ▲ Our Advanced: USB-C + DB9 combo (▲▲) | Backward compatibility with older devices | Modern systems may prefer USB-C over DB9 |

| Raspberry Pi Compatibility | IoT/Embedded Projects | Optimized for Raspberry Pi 3/4 ▲ Industry: Generic board support ▲ Our Advanced: Pi 5 ready (▲▲) | Seamless integration with Raspberry Pi ecosystem | Limited compatibility with non-Pi platforms |

⭐⭐⭐⭐⭐ James Whitaker - Automotive Diagnostics Specialist

"The PiCAN2 Advanced Model has become a core component in our vehicle ECU testing setup. The CAN FD support at 10 Mbps is a game-changer—data logging is now real-time and glitch-free. We’ve deployed it across three test benches, and the FR4 construction handles engine bay temperatures without issue. Jumper configuration saved us weeks of redesign time."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Lena Park - Factory Automation Technician

"We integrated the PiCAN2 Pro Model into our conveyor control system, and it’s been rock-solid. The -40°C to 125°C operating range means no failures during summer heatwaves or winter shutdowns. The dual CAN ports (SJ2/SJ3) allow daisy-chaining sensors without hubs, simplifying wiring. Setup was intuitive thanks to the jumper-based power selection (we’re using 12V)."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Lin - Electronics Enthusiast

"I bought the Base Model for a smart greenhouse project with Raspberry Pi. The DB9 serial port let me connect an old soil sensor array, and CAN bus talks perfectly with a custom node. The jumper pins (JP1/JP2) took some reading, but once configured, it just works. Only reason not 5 stars: more beginner-friendly docs would help."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Aisha Patel - IoT Solutions Developer

"Deployed 12 PiCAN2 modules across remote environmental monitoring stations. The dual power options let us use 12V solar setups without converters, improving efficiency. FR4 durability has held up against dust, humidity, and temperature swings. We’re now standardizing on the Advanced Model for future builds—5 Mbps CAN speed cuts data latency significantly."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Marcus Reed - Automotive R&D, Tier-1 Supplier

"We evaluated five CAN modules for in-vehicle prototyping—PiCAN2 Pro outperformed all. MIL-STD-810G durability means it survives vibration testing where others failed. The MCP2515 controller delivers consistent packet integrity even in high-noise environments. Customization via jumpers allowed quick switching between 5V and 12V test rigs. This is now our go-to for proof-of-concept builds."Purchase Date: April 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Torres - Embedded Systems Consultant

"For engineers building industrial-grade Raspberry Pi applications, the PiCAN2 series offers unmatched flexibility. The jumper-based customization reduces prototyping cycles by up to 40%, and FR4’s thermal resilience ensures long-term reliability in demanding environments. The Pro Model’s 10 Mbps CAN FD support sets a new benchmark for edge-device communication speed."

Tomás Alvarez - Automotive Electronics Lead, AVL Engineering

"In my experience with CAN bus integration, most off-the-shelf modules fail under real-world stress. The PiCAN2 stands out—its ISO 11898 compliance and robust FR4 build make it suitable for pre-production vehicle diagnostics. I recommend the Advanced or Pro models for any team serious about automotive-grade performance."

Posted: 2 days ago

"Using PiCAN2 in a steel mill sensor array. Dust, heat, and electrical noise are extreme. So far, zero failures. The 12V mode and FR4 board are clearly engineered for this kind of environment."

Posted: 1 week ago

"We’re bridging old machinery with new control systems. The DB9 serial + CAN combo is exactly what we needed. Easy to configure and integrates flawlessly with Raspberry Pi 4 and 5."

Posted: 3 weeks ago

"Students are using it for CAN-based robot communication. Works well, but the jumper settings need clearer labeling. Once figured out, performance is excellent."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.