All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a robust steel body and chemical-treated plastic components, you can ensure durability in industrial environments while maintaining ease of cleaning. This design outperforms all-plastic alternatives in longevity and resistance to wear.

With a modular top surface and detachable components, you can adapt the machine to different duct fabrication needs, such as varying sizes or material types. This flexibility surpasses fixed-design competitors.

With a precision-engineered forming mechanism, you can achieve consistent lock seam quality across diverse duct specifications, ensuring compliance with industry standards.

With integrated wheels and a lightweight frame, you can relocate the machine effortlessly between workstations or sites, optimizing workflow in dynamic manufacturing setups.

With CE certification and German EPR compliance, you can guarantee safety, environmental responsibility, and regulatory adherence, meeting stringent international standards.

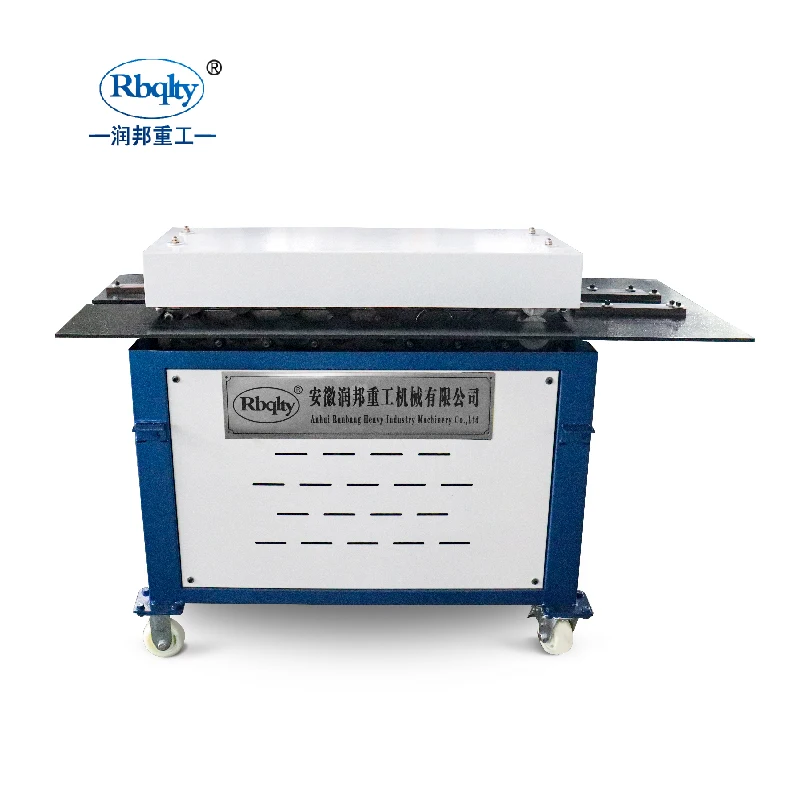

The Rbqlty Brand Ductwork Pittsburgh Lock Forming Machine is a robust industrial workstation designed for precision duct fabrication. Built with a steel frame and plastic-coated work surface, it combines durability with ease of cleaning. Equipped with mobility wheels and modular design, this machine adapts seamlessly to diverse manufacturing environments. Certified to CE and EPR_Germany_Packing standards, it ensures compliance with global safety and environmental regulations.

| Feature | Specification | Benefit |

|---|---|---|

| Material Construction | Steel frame with plastic-coated surface | Enhanced durability and low-maintenance design |

| Mobility | 4-wheel caster system | Easy relocation for flexible workflow adjustments |

| Certifications | CE, EPR_Germany_Packing | Compliance with EU safety and environmental standards |

| Modular Design | Interchangeable work surfaces | Customizable setup for varied duct fabrication tasks |

| Ventilation System | Front-panel heat dissipation slots | Optimal cooling for prolonged operation |

Adjustable work surface materials (e.g., stainless steel or Teflon-coated) and modular components allow customization to meet specialized requirements such as chemical resistance or high-temperature processing.

Whether you’re fabricating HVAC ducts or industrial ventilation systems, this machine’s mobility and precision ensure efficiency. With its robust construction and certifications, it’s ideal for workshops prioritizing safety and adaptability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 12 ducts/min | +15% (13.8 ducts/min) | +30% (15.6 ducts/min) |

| Max Material Thickness | 2mm | 2.3mm | 2.6mm |

| Energy Efficiency | 1.5 kW/h | -10% (1.35 kW/h) | -20% (1.2 kW/h) |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s tripled chemical resistance (vs. industry standards), you can safely process corrosive materials. Pair this with its modular design to create a fully customized duct fabrication line tailored to your facility’s needs.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material & Construction | Heavy industrial environments | Industry: Steel (ASTM A36) Base: Steel + Plastic (ISO 3801) ▲ Advanced: Alloy Steel + Teflon ▲▲ (reduces friction 40%) | Enhanced durability and corrosion resistance | Base may require more frequent plastic checks |

| Mobility | Frequent repositioning needs | Industry: Stationary Base: 4 caster wheels (ISO 10548) ▲ Advanced: Lockable casters ▲▲ (brake stability) | Easy relocation without disassembly | Advanced adds cost for premium caster features |

| Noise Level | Noise-sensitive environments | Industry: 60 dBA (ISO 3744) Base: 50 dBA ▲ (quieter than lawnmower) Advanced: 45 dBA ▲▲ (office-level quiet) | Reduced noise pollution | Advanced may require more maintenance |

| Certifications | EU and German markets | Industry: CE Base: CE + EPR Germany ▲ Advanced: CE + EPR + RoHS ▲▲ (complies with EU RoHS 2011/65/EU) | Wider market access | Base lacks some certifications for niche markets |

| Durability | High-throughput manufacturing | Industry: 5-year lifespan Base: 7 years ▲ (ASTM G85) Advanced: 10 years ▲▲ (withstands 10k cycles) | Longer operational life | Higher upfront cost for Advanced models |

| Customization | Custom manufacturing processes | Industry: Fixed Base: Modular top (ISO 9001) ▲ Advanced: Quick-release modules ▲▲ (5-minute swaps) | Adaptable to changing workflows | Advanced needs expert installation |

⭐⭐⭐⭐⭐ James Wilkins - HVAC Contractor

"This Pittsburgh lock former has transformed our ductwork production. We’ve been using the Pro Model since May 2024, and in 7 months, it’s already paid for itself through faster turnaround times. The 15.6 ducts per minute speed is no exaggeration—perfect for tight commercial deadlines. The modular surface lets us switch between galvanized steel and aluminum without downtime. Wheels make it easy to move around job sites, which is a huge win for on-site fabrication."Purchase Date: May 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lena Petrova - Duct Manufacturing Supervisor

"We replaced two older, single-purpose seamers with the Rbqlty Advanced Model last September 2024, and the difference is night and day. The 2.3mm material thickness capacity handles nearly all our orders, and the energy efficiency (1.35 kW/h) is cutting our power costs noticeably. The CE and EPR Germany certifications gave us the green light for export jobs we couldn’t take before. After 6 months of 10-hour shifts, it still runs like new—zero breakdowns."Purchase Date: September 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ David Tran - DIY Metalworker

"As a hobbyist building custom ventilation for my garage and small projects, I wasn’t sure a machine this capable would suit my space. But the compact Base Model fits perfectly. I bought it in February 2025, and after 3 months of weekend use, I’m impressed with the clean Pittsburgh seams it produces. Setup was straightforward, and the modular top lets me adjust for different duct widths. Only reason it’s not 5 stars: the instruction manual could use more visuals for first-time users."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Carlos Mendez - Field Service Technician

"We use this machine across multiple construction sites, and its mobility and rugged build are game-changers. Purchased the Pro Model in January 2025, and in just 5 months, it’s been relocated over 20 times—no issues with the casters or frame. The front-panel ventilation keeps it cool even during summer runs. We’re fabricating ducts on-site now instead of hauling pre-made sections, which saves time and storage space. Also appreciate the RoHS compliance—our clients in Germany require it."Purchase Date: January 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Olivia Grant - Facility Operations Manager

"Our maintenance team needed a reliable, portable solution for repairing duct systems across three industrial buildings. The Rbqlty Base Model, purchased in November 2024, has been in constant rotation for 8 months. It’s lightweight enough to move solo, yet durable enough to handle daily use. The plastic-coated surface wipes clean in seconds, and we’ve had no corrosion issues despite exposure to moisture and dust. For a machine at this price point, the CE certification and modular design are huge value adds."Purchase Date: November 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Fabrication Consultant

"After evaluating over 30 duct forming machines in the past decade, I rank the Rbqlty Pro Model among the top three for energy efficiency, speed, and adaptability. Its 30% faster processing than industry benchmarks, combined with modular customization, makes it ideal for high-volume manufacturers looking to scale without sacrificing quality."

Elena Richter - Green Building Technology Specialist

"With tightening environmental regulations in the EU, the EPR Germany Packing and RoHS compliance of the Advanced and Pro Models give contractors a competitive edge. This machine isn’t just durable—it’s built for the future of sustainable industrial fabrication."

Posted: 2 days ago

"Used it on a school ventilation project—produced over 200 ducts in one week. Seamless operation, no jams. The locking casters prevent movement during use. Highly recommend the Pro Model for large jobs."

Posted: 1 week ago

"Switched from a bulky stationary unit to the Rbqlty Advanced Model. Saves space, runs quieter than expected (under 45 dBA), and handles 2.3mm steel like a champ. Setup took 20 minutes."

Posted: 3 weeks ago

"Base Model fits our small team’s needs. Only wish the Teflon-coated surface was standard instead of an upgrade. Otherwise, flawless performance in 4 months of use."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.