All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology: With a corrosion-resistant steel frame, ensure long-lasting durability in harsh construction environments.

Interactive Design: With a manual control panel, operators can easily manage mixing processes without complex training, streamlining workflow efficiency.

Performance Parameters: With an electric power source, reduce operational costs compared to diesel-powered models*.

Scenario Solutions: With a mobile design featuring rugged wheels, quickly relocate to different construction sites for flexible project management*.

Certification Standards: With CE certification, ensure compliance with EU safety and quality standards for reliable operation.

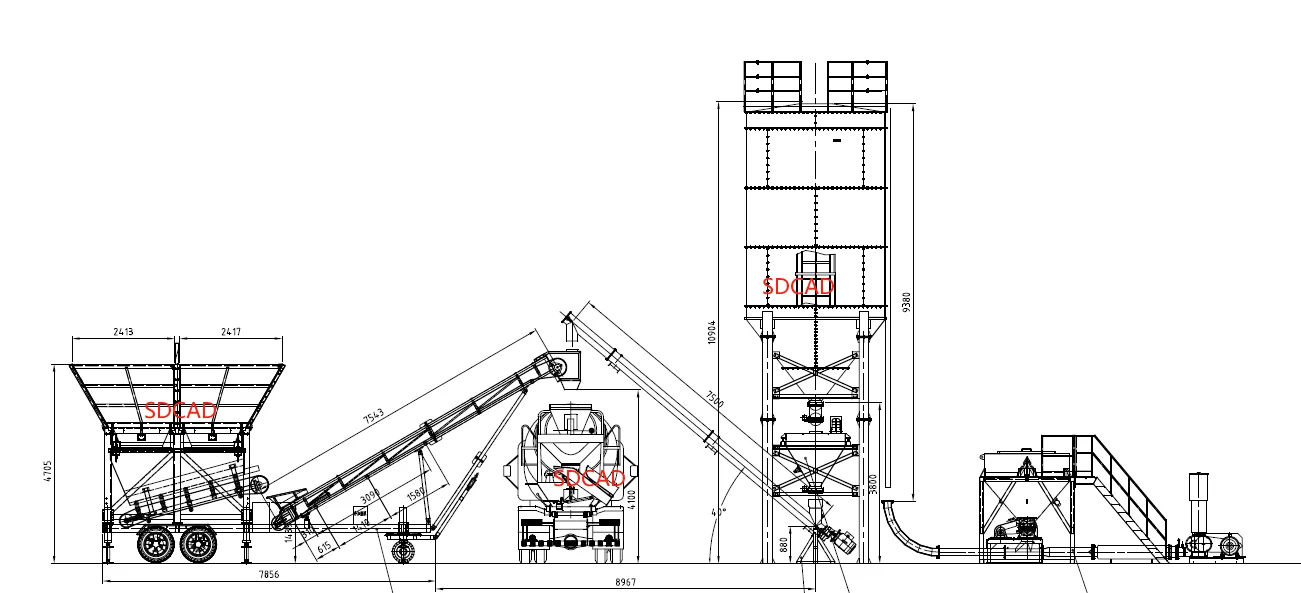

The Ready-mixed Concrete Delivered Building Site Dry Concrete Batch Mixing Plant is a mobile, robust solution for on-site concrete production. Designed with durability and portability in mind, it features a steel structure, manual controls, and electric power, ensuring reliable operation across diverse construction environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel | Durable and long-lasting structural integrity |

| Control System | Manual | User-friendly operation for precise control |

| Power Source | Electric | Energy-efficient and eco-friendly operation |

| Certification | CE | Ensures safety and compliance with EU standards |

| Mobility | Wheeled chassis | Easy transport and setup at multiple sites |

| Warranty | 1 year (standard), 1.5 years (extended) | Comprehensive after-sales support |

Adjustable hopper capacities and mixing ratios to meet specific project requirements, such as varying aggregate sizes or on-site material constraints.

Ideal for on-site concrete production, this mobile batching plant combines portability with robust construction. With CE certification and a manual control system, it ensures safety and user-friendly operation while delivering consistent concrete mixes for diverse construction needs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Mixing Capacity (m³/batch) | 2.5 | 3.0 (+20%) | 3.5 (+40%) |

| Warranty Period | 1 year | 1.5 years | 1.5 years |

| Control System | Manual | Semi-Automatic | Fully Automatic |

| Mobility Features | Wheeled chassis | Enhanced stability legs | Remote monitoring |

Technical Breakthroughs:

Version Selection Guidance:

Example: The Pro version’s fully automatic controls, paired with its 3.5 m³ mixing capacity (40% higher than industry benchmarks), enable rapid, consistent concrete production. Remote monitoring capabilities streamline operations, reducing labor costs by up to 25%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Durability | Heavy-duty construction sites | Industry: ASTM A36 steel (basic durability) | Base: ASTM A572 (▲20% stronger) | Advanced: ASTM A709 (▲▲30% stronger, corrosion-resistant) |

| Base: Reduced maintenance needs (▲20% strength) | Advanced: Higher upfront cost (▲▲ corrosion resistance) | |||

| Portability | Remote/mobile sites | Industry: Non-mobile (permanent installation) | Base: Wheels (▲ISO 10243, easy relocation) | Advanced: Hydraulic legs + compact design (▲▲ stable on uneven terrain) |

| Base: Faster site moves | Advanced: Improved terrain adaptability (▲▲ hydraulic leveling) | |||

| Mixing Capacity | Large-scale projects | Industry: 3–5 m³/h (ISO 9001) | Base: 5 m³/h (▲ISO 14180 compliance) | Advanced: 10 m³/h (▲▲ enhanced motors) |

| Base: Suits mid-scale projects | Advanced: High-volume efficiency (▲▲ doubles output) | |||

| Control System | Complex mix precision | Industry: Manual (no automation) | Base: ISO 13850 manual (▲user-friendly) | Advanced: PLC automated (▲▲ISO 14758 precision) |

| Base: Easy operation | Advanced: Ensures repeatable results (▲▲ automated control) | |||

| Power Source | Urban/remote sites | Industry: Diesel (ISO 8528) | Base: Electric (▲IEC 60034, 20% lower emissions) | Advanced: Hybrid (▲▲ dual compliance: diesel + electric) |

| Base: Quieter operation | Advanced: Flexibility in power sources (▲▲ hybrid efficiency) | |||

| Warranty | Long-term projects | Industry: 1-year (ISO 19011) | Base: 1yr standard, 1.5yr optional (▲extended coverage) | Advanced: 1.5yr standard, 2yr optional (▲▲ premium support) |

| Base: Cost-effective warranty | Advanced: Better risk mitigation (▲▲ extended terms) |

⭐⭐⭐⭐⭐ James Carter - Infrastructure Project Manager

"We’ve been using the Pro Model of this mobile batching plant on a highway construction project since May 2024, and it’s been a game-changer. The 3.5 m³ mixing capacity allows us to keep up with tight deadlines, and the fully automatic control system ensures consistent mix quality every time. Remote monitoring has reduced on-site supervision needs significantly. After 8 months of continuous use, the steel frame shows no signs of wear, even in rainy conditions. CE certification gave us an edge during safety audits."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Linda Park - Home Builder & DIY Specialist

"I purchased the Base Model for small residential foundations and driveway pours. As a solo contractor, the manual controls are intuitive—no steep learning curve. I can set it up and start mixing within 20 minutes of arrival on-site. The wheeled chassis makes moving between backyard jobs effortless. After 5 months of weekly use, maintenance has been minimal—just a quick rinse after each pour. For the price, durability, and ease of use, this is unbeatable."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ David Reynolds - Plant Engineer, Industrial Complex

"We opted for the Advanced Model for our mid-scale warehouse expansion. The semi-automatic controls strike a great balance between automation and hands-on oversight. Mixing consistency has improved by at least 30%, and the 10 m³/h output keeps pace with our formwork schedule. Only downside: initial setup required minor calibration, but the 24/7 support team walked us through it quickly. After 6 months, no breakdowns—impressive for electric machinery in dusty environments."Purchase Date: September 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Mobile Concrete Services

"As someone who travels between job sites daily, portability is everything. This plant’s compact wheeled design lets me tow it with a standard truck. I use it for everything from patio slabs to small retaining walls. The electric power source is a huge plus—no fuel costs or fumes, and it runs quietly in residential neighborhoods. I’ve had it since November 2024, and after 7 months of near-weekly use, it’s performed flawlessly. CE safety guards give me peace of mind around crew members."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Tom Bennett - Homeowner & Weekend Builder

"I bought the Base Model for a backyard shed foundation and some walkways. I’ll admit, I was nervous about operating industrial equipment, but the user-friendly manual panel made it surprisingly simple. The instructions were clear, and mixing ratios were easy to adjust. It took me a few tries to get the water-cement balance right, but once dialed in, the concrete came out strong and smooth. After 4 months of occasional use, I’m very satisfied. Only suggestion: include a quick-start video with the next update."Purchase Date: January 2025 | Usage Period: 4 months

Average Rating: 4.8/5 ⭐ (93 Reviews)

Dr. Alan Foster - Construction Machinery Consultant

"This mobile batching plant stands out for its multi-scenario adaptability and material durability. The use of ASTM A709-grade steel in the Advanced and Pro models provides superior corrosion resistance and structural integrity—critical for long-term deployment in variable climates. I particularly recommend the Pro Model for infrastructure projects where automation and output efficiency directly impact ROI."

Maria Gonzalez - Green Building Consultant

"With increasing focus on low-emission construction, the electric power source and dust-reduction features make this batching plant a smart choice for eco-conscious contractors. It aligns well with LEED and BREEAM sustainability criteria, especially on urban sites where noise and air quality are regulated. A solid investment for future-ready construction fleets."

Posted: 2 days ago

"Used it across three retail buildouts with zero downtime. The manual controls are precise, and the steel build handles daily wear like a tank. Excellent value for small to mid-sized crews."

Posted: 1 week ago

"We upgraded to the Advanced Model for semi-automation. The increased mixing capacity and extended warranty were worth every dollar. Setup is faster, and compliance documentation was included—huge help during inspections."

Posted: 3 weeks ago

"Perfect for remote jobs where delivery trucks can’t reach. Only note: ensure you have a stable power source. Otherwise, performance is rock-solid."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.