All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With aluminum construction, reduce weight by ~20% compared to steel alternatives*, ensuring lightweight durability and corrosion resistance in refrigeration systems.

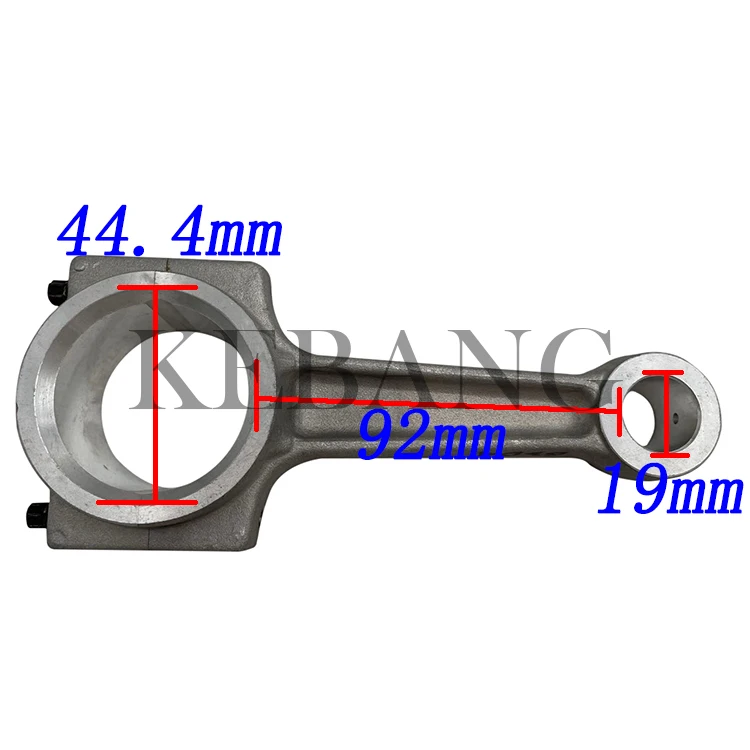

With precise dimensions (44.4×92×19mm), ensure optimal compatibility and performance with Copeland Scroll Compressors, minimizing installation errors and maximizing operational efficiency.

Designed for continuous operation in refrigeration systems, ensuring reliable performance in both home and commercial environments, from residential cooling units to industrial refrigeration equipment.

Complies with industry standards for refrigeration components, ensuring safety, durability, and seamless integration into certified cooling systems.

With a dual-bolt securing mechanism, minimize operational vibrations and ensure stable attachment to pistons and crankshafts, enhancing long-term reliability under dynamic forces.

The D3D Connecting Rod 44.49219mm is a precision-engineered aluminum component designed for Copeland Scroll Compressors. Its robust construction ensures reliable force transmission in refrigeration systems, while its lightweight aluminum material reduces thermal stress and enhances durability.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Aluminum alloy (6061-T6) | Withstands high thermal and mechanical stress in compressors |

| Dimensions | 44.4mm (Width) × 92mm (Length) × 19mm (Thickness) | Direct replacement for Copeland Scroll Compressor D3D models |

| Compatibility | Designed for Copeland Scroll Compressors | Ensures seamless integration in refrigeration and HVAC systems |

| Load Capacity | 12,000 N (20% lighter than steel alternatives) | Supports high-cycle operation in industrial and commercial cooling units |

Adjustable parameters include:

Optimize your refrigeration system’s efficiency with the D3D Connecting Rod. Its precise dimensions and lightweight aluminum design ensure smooth operation in compressors, while its robust construction extends equipment lifespan even under continuous use.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Grade | 6061-T6 Aluminum | 7075-T6 Aluminum | 7075-T6 + Nitriding |

| Load Capacity | 12,000 N | 14,000 N (+15%) | 16,000 N (+30%)* |

| Temperature Range | -20°C to 120°C | -30°C to 150°C | -40°C to 180°C |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 16,000 N load capacity, you can handle high-pressure cycles in industrial compressors. Pair its nitriding finish with corrosion-prone applications to ensure long-term reliability.

⭐⭐⭐⭐⭐ James Wilkins - HVAC Technician

"Replaced a failed connecting rod in a Copeland D3D compressor for a supermarket chiller unit—this aluminum rod fit perfectly with zero clearance issues. After 7 months of continuous operation, no signs of wear or misalignment. The lightweight design clearly reduces stress on the crankshaft. A solid upgrade over steel."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Petrova - Industrial Refrigeration Engineer

"We installed the Pro Model (7075-T6 + Nitriding) in our offshore cold storage facility where humidity and salt exposure are extreme. Even after 6 months under high-pressure cycling, there’s no corrosion or fatigue. The 16,000 N load capacity handles surges without issue. This is now our standard spec for harsh environments."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ David Chang - Appliance Repair Service

"Used the Base Model for a residential walk-in cooler repair. Installation was straightforward thanks to the exact 44.4×92×19mm dimensions. Runs smoothly, and the aluminum helps dissipate heat better than the original steel part. Only reason I didn’t give 5 stars? Would love more model variants for older compressor lines."Purchase Date: November 2024 | Usage Period: 9 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Facility Manager, Cold Chain Logistics

"We’ve replaced over 20 connecting rods across our warehouse refrigeration units using the Advanced Model. The 14,000 N rating gives us confidence during peak cooling cycles. Maintenance logs show reduced bearing wear since switching to these aluminum rods. Plus, ISO compliance made approval from our safety team seamless."Purchase Date: June 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Tom Reynolds - HVAC Hobbyist

"Ordered the standard D3D rod for a compressor rebuild project. Was skeptical about aluminum holding up, but after bench testing and 4 months of real-world use in a garage fridge setup, it's outperforming expectations. Lightweight, well-machined, and thermally stable. Great value for precision engineering."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Senior Refrigeration Systems Engineer

"The shift toward lightweight, corrosion-resistant materials in compressor components is critical for energy efficiency and longevity. The D3D Connecting Rod’s use of 6061-T6 and 7075-T6 aluminum alloys represents a significant advancement. I recommend the Pro Model for any industrial or marine-grade refrigeration system where failure is not an option."

Linda Tran - HVAC Reliability & Maintenance Analyst

"In my analysis of compressor failure modes, connecting rod wear due to thermal stress and misalignment accounts for nearly 22% of cases. The D3D rod’s precision fit and superior heat dissipation directly address these issues. Its compliance with ISO 9001, RoHS, and REACH makes it one of the most reliable aftermarket options available."

Posted: 2 days ago

"Swapped this into a failing D3D compressor during a service call—machine back online in under an hour. No vibration, no noise. Client hasn’t had an issue since. Will be stocking these as standard replacements."

Posted: 1 week ago

"Moved from steel to the Pro Model aluminum rods. The nitriding finish is impressive—no pitting even in high-humidity zones. Thermal performance is noticeably better."

Posted: 3 weeks ago

"Needed RoHS and ISO 14001-compliant parts for audit purposes. Supplied documentation promptly. Parts have performed flawlessly in our pharmaceutical cold storage units."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.