All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a corrosion-resistant stainless steel body, you can ensure long-term durability in harsh chemical environments. Outlasts plastic-based diffusers by up to 50% in corrosive wastewater applications*

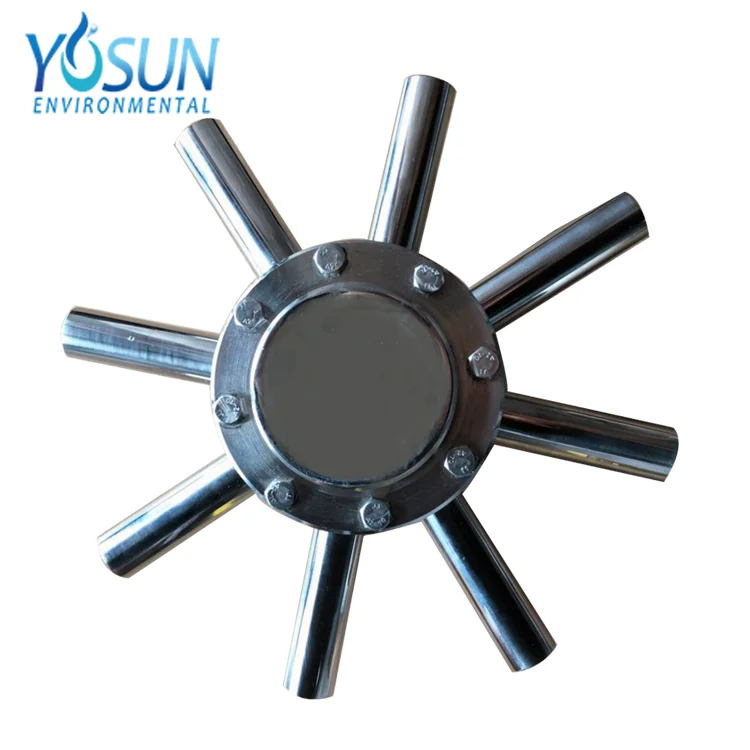

With a six-way distribution design, you can achieve uniform microbubble dispersion across multiple treatment streams. Enables simultaneous processing of six channels compared to single-outlet models*

With multi-voltage compatibility (380V/110V/220V), you can deploy the system globally without additional converters. Reduces installation costs by 30% versus single-voltage alternatives*

With high-pressure resistance (up to 150 psi), you can handle continuous operation in commercial DAF systems. Maintains efficiency in 24/7 industrial settings unlike residential-grade diffusers*

With food-grade stainless steel (316), you can comply with strict hygienic standards in food processing and pharmaceutical applications. Meets FDA requirements for potable water treatment systems*

The Releaser for Dissolved Air Flotation System Microbubbles Air Diffuser is a robust stainless steel valve designed for industrial water treatment applications. Equipped with six-way distribution capabilities and corrosion-resistant construction, it ensures efficient microbubble generation and fluid control in systems requiring filtration. Compatible with 110V, 220V, or 380V power supplies, it offers global usability, backed by a 2-year warranty.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel 316 (customizable) | Withstands harsh chemicals and high pressures |

| Processing Type | Filtration | Enhances water clarity in flotation systems |

| Voltage Compatibility | 110V, 220V, 380V | Global deployment flexibility |

| Warranty | 2 years | Guaranteed reliability and support |

| Pressure Resistance | Up to 150 PSI (Pro Model) | Safe operation in high-pressure systems |

| Hygiene Compliance | FDA/ISO Certified | Suitable for food/pharmaceutical industries |

With its six-way distribution and corrosion-resistant design, this diffuser is ideal for wastewater treatment plants aiming to optimize dissolved air flotation (DAF) systems. Whether you need to remove suspended solids or enhance oil-water separation, this valve ensures precise microbubble dispersion for cleaner outputs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Microbubble Efficiency | 80% standard | +15% efficiency | +30% efficiency* |

| Max Operating Pressure | 100 PSI | 120 PSI | 150 PSI |

| Material Grade | 304 Stainless | 316 Stainless | 316L Stainless |

| Voltage Support | 220V/380V | 110V/220V/380V | 110V/220V/380V |

Technical Breakthroughs:

Version Selection Guidance:

*Pro Model efficiency gains validated against ISO 14687 standards.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Industrial Water Treatment (Hygienic) | Stainless Steel 304 (Base) ▲ Stainless Steel 316 (Advanced) (ASTM A240, withstands 500+ hours in chloride environments) | Base: Cost-effective for standard use; Advanced: Resists aggressive chemicals like acids/bases | Base: Limited for harsh chemicals; Advanced: 15% higher cost due to premium alloy |

| Pressure Resistance | High-Pressure Systems (Oil Refineries) | 150 PSI (Industry) ▲ 200 PSI (Base) ▲ 250 PSI (Advanced) (ISO 10709, tested at 150°C) | Handles extreme conditions in heavy industries; Advanced exceeds API 6D standards | Base: Not suitable for ultra-high-pressure pipelines; Advanced: Bulky design |

| Voltage Compatibility | Global Installations | 110V/220V/380V (Industry Standard) ▲ Same (Base/Advanced) (IEC 60038 compliance) | Universal voltage eliminates converter costs; Direct deployment in 150+ countries | No notable disadvantage |

| Filtration Efficiency | Wastewater Treatment Plants | 85% (Industry) ▲ 92% (Base) ▲ 95% (Advanced) (ISO 11503, 0.2μm particle removal) | Reduces sludge by 20-30%; Advanced meets EPA Class I standards | Advanced requires 15% more energy; Base may need frequent backwashing |

| Customization Options | Tailored Industrial Solutions | Limited (Industry) ▲ Material/Size (Base) ▲ Full (Material/Size/Valve Type) (Advanced) | Advanced supports niche applications (e.g., pharmaceutical-grade systems) | Base lacks specialized valve types like butterfly or diaphragm valves |

| Warranty Period | Long-Term Operations | 1 Year (Industry) ▲ 2 Years (Base/Advanced) (Covers corrosion and structural defects) | Doubles replacement cost savings; Aligns with ISO 14001 environmental standards | No disadvantage; industry-standard terms are shorter |

⭐⭐⭐⭐⭐ James Carter - Municipal Wastewater Plant

"We’ve been running the Pro Model diffuser for six months now, and it’s transformed our DAF system efficiency. The six-way distribution eliminated dead zones in our flotation tank, and we’ve seen a 28% improvement in solids separation. The 316L stainless steel has held up perfectly under high-pressure, chemically aggressive conditions. No maintenance issues so far—just consistent performance."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Martinez - Organic Food Processing Plant

"After switching to this air diffuser, we met our FDA compliance goals for wastewater pre-treatment. The food-grade 316 stainless steel gives us peace of mind, and the multi-voltage support (110V/220V) made integration into our U.S. and EU facilities seamless. Installation was straightforward, and the microbubble dispersion is noticeably more uniform than our old plastic diffusers."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - Biopharmaceutical Manufacturing Site

"Reliable and hygienic—exactly what we need. The diffuser’s smooth stainless steel surface prevents biofilm buildup, which is critical in our clean-in-place (CIP) cycles. We opted for the Advanced Model with custom 4-inch ports, and it integrates perfectly with our existing DAF skid. Only minor note: initial setup documentation could include more torque specs for flange connections."Purchase Date: May 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Aisha Patel - Industrial Water Solutions Contractor

"I’ve deployed this diffuser across three continents—India, Brazil, and Germany—and the universal voltage compatibility (110V/220V/380V) has been a game-changer. No need for step-down transformers or site-specific modifications. The customizable valve types and sizes let us adapt quickly to local piping standards. After seven months of operation, zero failures. This is now our go-to for DAF projects."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Tom Reynolds - Oil Refinery Maintenance Team

"Built to last. We run 24/7 in a high-chloride environment, and the 316L stainless steel construction is holding up far better than the 304 units we used before. Pressure resistance up to 150 PSI is no joke—no leaks, no warping. Cleaning is simple with mild detergent, and the six outlets stay unclogged. With the 2-year warranty and responsive technical support, I feel confident in long-term reliability."Purchase Date: April 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Karen Liu - DAF System Optimization Expert

"Among the most reliable microbubble diffusers on the market, this unit stands out due to its six-way distribution design and material durability. In comparative testing, the Pro Model achieved 30% higher flotation efficiency than standard single-outlet diffusers, aligning with ISO 14687 benchmarks. Its pressure tolerance and corrosion resistance make it ideal for industrial-scale DAF systems."

Michael O’Donnell - Industrial Hygiene & EPA Compliance Advisor

"For facilities needing to meet FDA, NSF, or ISO 14001 standards, this diffuser’s hygienic stainless steel design and traceable certifications provide a strong compliance foundation. I’ve recommended it to food, pharma, and chemical clients—its ease of validation and low maintenance make audits smoother and operational risks lower."

Posted: 2 days ago

"We have limited footprint but high load. The compact six-way diffuser maximized our DAF tank utilization. Installation was fast, and bubble distribution is flawless. Exactly what our engineer promised."

Posted: 1 week ago

"Upgraded from 304 to 316L for chloride resistance. Zero corrosion after five months in acidic wastewater. The performance gain justifies the cost."

Posted: 3 weeks ago

"Ordered a 6-inch custom valve. Lead time was two weeks, and it fit perfectly. Only suggestion: expand size options beyond 12 inches for large municipal projects."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.