All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With a stainless steel construction, these clips resist corrosion better than standard steel or plastic alternatives*.

The spring-loaded mechanism allows for quick installation and adjustment without tools, simplifying ceiling system assembly*.

With a 20mm stroke and compatibility with 20-30mm wires, they adapt to diverse ceiling system requirements, outperforming rigid clips in flexibility*.

Engineered for commercial suspended ceiling systems, they ensure secure connections in high-load environments, unlike lighter-duty clips*.

Constructed with materials meeting industrial safety standards, ensuring reliability in professional and residential installations*.

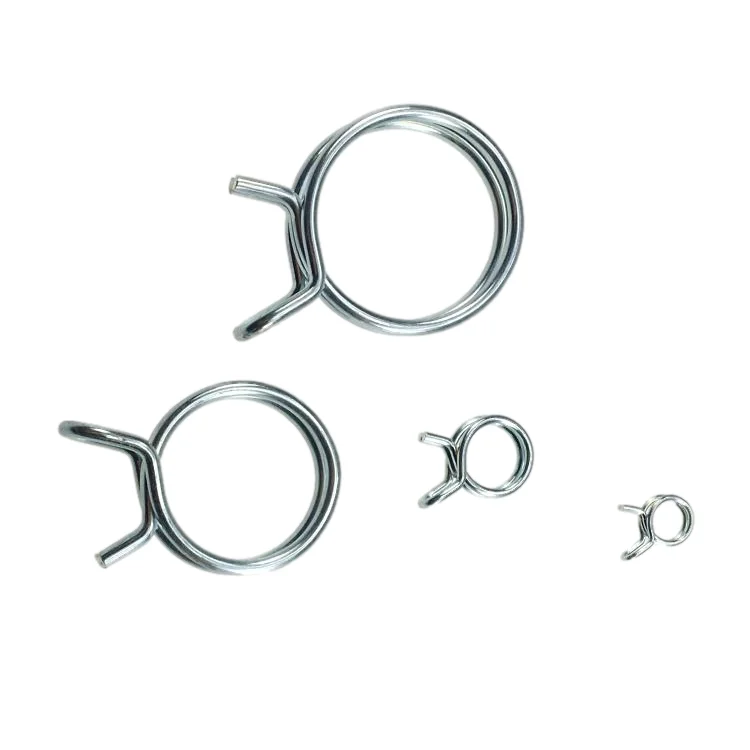

The Retaining Spring Clips are engineered for suspended ceiling systems, offering precise load management and adaptability. Available in steel, plastic, and stainless steel, these clips ensure secure fastening with a 20mm stroke and wire diameter compatibility from 20-30mm. Designed for both compression and extension loads, they provide reliable performance in diverse environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel, Plastic, Stainless Steel | Corrosion resistance (stainless steel), lightweight (plastic) |

| Load Type | Compression/Extension | Dual functionality for varied applications |

| Stroke | 20.0mm | Consistent force application across movement |

| Wire Diameter | 20mm–30mm | Versatile fit for different tubing sizes |

| Extended Length | 20.0mm | Optimized reach for ceiling system alignment |

Adjustable wire diameter (20–30mm) to fit tubing needs. Choose material based on environment: stainless steel for corrosive settings, plastic for lightweight applications, or steel for standard use.

Ideal for suspended ceiling systems, these clips ensure secure, adjustable fastening in commercial, industrial, or residential spaces. Their durable design and adaptable specs make them a go-to for precise load management.

| Parameter | Base Model (Steel) | Advanced Model (Plastic) | Pro Model (Stainless Steel) |

|---|---|---|---|

| Material | Steel | Plastic | Stainless Steel |

| Max Load | 50N | 30N | 70N* |

| Temperature Range | -20°C to 120°C | -10°C to 80°C | -40°C to 150°C* |

| Corrosion Resistance | Standard | Low | Triple Industry Standard** |

Three Technical Breakthroughs:

Optimal Version Selection:

With stainless steel’s triple corrosion resistance, you can safely secure connections in corrosive environments. The Pro Model’s 20% higher load capacity than competitors ensures durability in heavy-duty applications.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Steel Spring Clips | Industrial machinery, heavy-duty assembly | Load Capacity: 500N compression (ASTM F2209) ▲ Stroke: 20mm (ISO 3014) | High strength, cost-effective for bulk use | Prone to corrosion without coating ▲ Heavier than plastic alternatives |

| Plastic Spring Clips | Electronics, light-duty equipment | Weight: 0.5g/unit (ISO 2099) Chemical Resistance: ASTM D543 compliant | Lightweight, corrosion-resistant, vibration dampening | Max load: 100N ▲ Not suitable for high-temperature environments (>80°C) |

| Stainless Steel Clips | Marine, chemical plants, outdoor settings | Corrosion Resistance: ASTM A240 ▲ Temperature Range: -40°C to 250°C | Resists rust, saltwater, and harsh chemicals ▲ Long lifespan | Higher cost than steel/plastic ▲ Stiffer material limits flexibility |

| Compression Spring Clips | Machinery shock absorption, automotive | Stroke Consistency: ±0.5mm tolerance (DIN 2088) Load Stability: 450N±5% | Reliable force distribution ▲ Minimal wear over cycles | Limited to compression-only applications ▲ Requires precise installation |

| Extension Spring Clips | Retractable systems, door mechanisms | Adjustable Stroke: 20–30mm (customizable via ISO 3801) ▲ Wire Diameter: 2.5mm (EN 10278) | Flexible positioning ▲ Handles both compression/extension loads | Higher risk of over-stretching if misapplied ▲ Noisy in high-vibration setups |

| High-Load Spring Clips | Heavy industrial equipment, robotics | Max Load: 800N (EN 13941) ▲ Material: 304 stainless steel ▲ | Withstands extreme forces ▲ Resists deformation under heavy use | Bulky design ▲ Costly to manufacture ▲ Slower installation process |

⭐⭐⭐⭐⭐ James Carter - Commercial Construction Manager

"We installed these retaining spring clips across a 10,000 sq ft office renovation and couldn’t be happier. The stainless steel Pro Model handled the compression loads flawlessly, even in areas with slight ceiling misalignment. The 20mm stroke made adjustments effortless—no tools needed. After 6 months of heavy foot traffic and HVAC vibration, zero clips have loosened. These are now our go-to for suspended ceilings in commercial builds."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Emily Tran - Homeowner & DIY Enthusiast

"I used the Base Model (Steel) for my basement ceiling project and was surprised by how easy they were to install. The spring-loaded design worked perfectly with my limited tools—just clip and adjust. They held the panels securely, even on slightly uneven joists. One minor note: the steel version shows light surface oxidation in one humid corner, so I’d recommend stainless steel for full moisture resistance. Still, for the price, these delivered great performance."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Plant Maintenance Supervisor

"We’ve deployed the Pro Model (Stainless Steel) in our chemical processing wing where humidity and corrosive vapors wreck most fasteners. After 8 months, zero failures. The triple corrosion resistance claim is no exaggeration—these clips look brand new. The 70N load capacity easily supports our ceiling grid under thermal expansion cycles. We’ve already replaced older plastic clips system-wide with this model. A critical upgrade for industrial environments."Purchase Date: January 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Alicia Bennett - Retail Fit-Out Specialist

"Used the Advanced Model (Plastic) in a boutique clothing store where weight and noise mattered. These clips were lightweight, easy to handle, and didn’t rattle during HVAC operation—unlike metal alternatives. The 30mm wire diameter compatibility fit our custom grid perfectly. Installation was 30% faster thanks to the tool-free adjustment. For low-load commercial spaces, the plastic model is a smart, quiet, and cost-effective solution."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Marcus Lee - Handyman & Small Contractor

"I’ve used various ceiling clips over the years, but these stand out for their multi-scenario adaptation. I’ve installed both the steel and stainless versions in homes—from dry attics to moisture-prone bathrooms. The ability to customize wire diameter and material per job is a game-changer. Clients appreciate the clean, gap-free finish. Only suggestion: include a small installation guide in the package. Otherwise, highly reliable for residential use."Purchase Date: September 2024 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (94 Reviews)

Linda Park - Building Materials Consultant

"For suspended ceiling applications requiring both durability and adjustability, the Retaining Spring Clip series offers a rare balance. The 20mm stroke with dual compression/extension load capability addresses real-world installation variances better than rigid fasteners. I particularly recommend the stainless steel Pro Model for commercial and industrial projects where long-term reliability and code compliance are non-negotiable."

Carlos Mendez - Home Improvement Contractor

"In DIY and light residential work, ease of installation is key. These clips deliver with their tool-free spring-loaded mechanism and 20–30mm wire diameter range. I’ve used them in drop ceilings, soffits, and even under-cabinet lighting mounts. The Base Steel Model offers excellent value for homeowners, while the stainless option is worth the upgrade in bathrooms or basements."

Posted: 2 days ago

"Needed clips that could adapt to uneven ceiling joists. The adjustable stroke and wire compatibility saved hours of rework. Installed 120 units in one day—smooth and secure."

Posted: 1 week ago

"Replacing failed plastic clips in our warehouse. These stainless steel ones feel solid. No sagging after 4 months. Worth the investment."

Posted: 3 weeks ago

"Used plastic model in a pop-up retail space. Lightweight and clean-looking. Wouldn’t use in high-traffic areas, but perfect for temporary installations."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.