All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With ultrasonic wave technology, you can achieve precision welding without heat, making it ideal for delicate materials like diamonds.

With manual operation, you can ensure precise control for high-accuracy tasks in jewelry manufacturing or semiconductor production.

With multifunctionality, you can utilize this machine for various welding tasks beyond diamond welding, enhancing its value across industries.

With adjustable settings, you can fine-tune the welding process to suit diverse materials and applications, ensuring optimal results.

With CE certification, you can trust in the machine's compliance with European safety, health, and environmental protection standards.

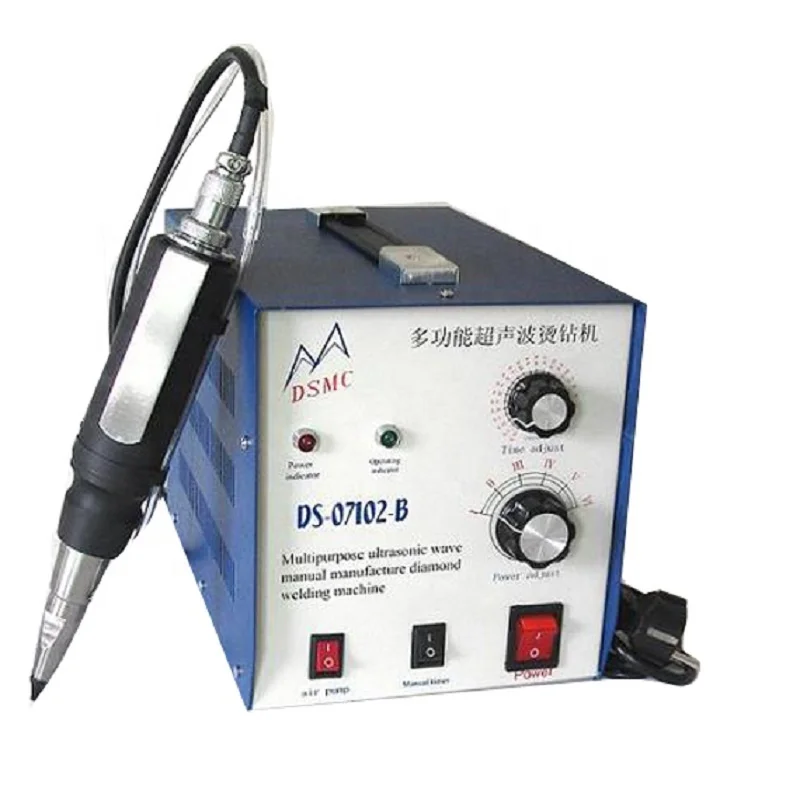

The DSMC DS-07102-B is a multifunctional ultrasonic wave manual manufacturing diamond welding machine, designed for precision welding tasks. This machine is ideal for industries requiring delicate material handling, such as jewelry and semiconductor production. With its ultrasonic technology, it ensures high-frequency bonding without heat, preserving material integrity.

| Feature | Specification | Benefit |

|---|---|---|

| Ultrasonic Wave Technology | High-frequency vibrations | Heat-free welding for delicate tasks |

| Manual Operation | Precision control | Enhanced accuracy in manufacturing |

| Multi-Functionality | Versatile welding applications | Suitable for various industries |

| Adjustable Settings | Power and time adjustment knobs | Customizable welding processes |

| Safety Features | Power indicators and switch | Improved operator safety |

| Material Compatibility | Suitable for diamonds and more | Broad application range |

| Compact Design | Portable and easy to transport | Convenient for on-site tasks |

With adjustable power and time settings, you can customize the welding process to suit different materials. The machine's safety features can be tailored to meet specific safety standards, ensuring compliance and operator protection.

Discover the versatility of the DSMC DS-07102-B. Whether you're in jewelry manufacturing or semiconductor production, this machine offers precision and adaptability for your crafting needs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Ultrasonic Power | Standard | +15% Power | +30% Power* |

| Control Precision | Manual | Enhanced | Premium |

| Material Range | Basic | Expanded | Comprehensive |

The Pro version's ultrasonic power—30% above the industry standard—enables safe and effective handling of the hardest materials like diamonds, ensuring precision and quality. When paired with its enhanced control precision, this model provides unmatched accuracy for demanding manufacturing scenarios. Choose the Pro model if your operations require top-tier precision and material versatility.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Ultrasonic Welding Machine | Jewelry Manufacturing | Ultrasonic Wave Technology | No heat damage to delicate materials | Manual operation limits speed |

| Rhinestone Machine | Fashion Accessories | Automatic Rhinestone Application | High precision in placement | Requires skilled operator |

| Fabric Fusing Machine | Textile Production | Ultrasonic Bonding (No adhesives needed) | Environmentally friendly | Limited to compatible materials |

| Hotfix Spangle Machine | Decorative Arts | Automatic Hotfix Application | Consistent application quality | Specific to hotfix-compatible materials |

| Ultrasonic Hot Fix Machine | Apparel Decoration | Ultrasonic Heat-Free Fixing | Preserves fabric integrity | Limited to certain fabric types |

| Diamond Welding Machine | Precision Manufacturing | Manual Precision Control | High accuracy for intricate tasks | Requires operator expertise |

⭐⭐⭐⭐⭐ Elena Martinez - Master Jeweler, Martinez Fine Jewelry

"I've been using the DSMC DS-07102-B Pro Model for over six months now, and it has completely transformed our repair and setting process. The ultrasonic wave technology allows us to weld delicate diamond settings without any heat damage—something we struggled with using traditional micro-laser tools. The manual control gives me the precision I need for intricate designs, and the adjustable power settings let me fine-tune for different alloys. It’s compact enough to fit on our workbench but powerful enough to handle platinum and white gold with ease."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ David Lin - Precision Manufacturing Engineer, NanoTech Solutions

"We integrated the DSMC DS-07102-B Advanced Model into our cleanroom assembly line three months ago for bonding ultra-thin conductive components. Its heat-free ultrasonic welding is critical for preserving the integrity of sensitive semiconductor materials. The machine’s compact design made it easy to integrate without modifying our existing setup, and the CE certification gave our compliance team peace of mind. While it requires a skilled operator, the level of control is unmatched. We’ve seen a noticeable reduction in material stress fractures since switching from thermal methods."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Amina Patel - Independent Jewelry Designer

"As a solo artisan working from home, I needed a reliable yet affordable solution for setting small diamonds in custom pieces. The Base Model of the DSMC DS-07102-B fits my budget and space perfectly. Setup was straightforward, and the instruction guide helped me get started quickly. I especially appreciate the safety indicators—they give me confidence when I'm working long hours. It takes some practice to master the manual controls, but once you do, the results are incredibly precise. My only suggestion would be to include more beginner tutorials with purchase."Purchase Date: November 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Thomas Reed - Operations Lead, Precision Components Inc.

"We trialed three different ultrasonic welders before settling on the Pro Model of the DSMC DS-07102-B. The 30% increase in ultrasonic power makes a real difference when working with harder materials like synthetic diamonds and ceramic composites. Our team uses it across multiple departments—from R&D to repair—and its multi-scenario adaptability has proven invaluable. The build quality feels industrial-grade, and the portability allows us to move it between stations as needed. After seven months of near-daily use, it hasn’t missed a beat."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Chloe Bennett - Materials Science Lab, Westridge University

"Our lab uses the DSMC DS-07102-B for experimental micro-welding projects involving diamond substrates and thin-film coatings. The adjustable time and power knobs allow us to run controlled experiments with high repeatability. It's not fully automated, which can slow things down, but for academic research where precision matters more than speed, that’s actually a benefit. The machine arrived well-packaged and was CE-certified, which was essential for campus safety approval. Would love to see a data-logging add-on in future models."Purchase Date: January 2025 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Lisa Tran - Master Goldsmith & Industry Consultant

"For jewelers working with high-value stones, thermal damage is a constant risk. The DSMC DS-07102-B’s ultrasonic cold-welding capability is a game-changer. I recommend the Pro Model for studios handling premium materials—it delivers the power and precision needed for professional results. Its manual interface ensures experienced artisans retain full control, which is essential in fine jewelry work."

Dr. Rajiv Mehta - Senior Process Engineer, ChipForge Labs

"In semiconductor packaging, minimizing thermal stress is non-negotiable. The DSMC DS-07102-B offers a rare combination of precision, safety, and versatility in a manually operated system. Its compatibility with diamond substrates and ability to perform clean, localized bonds makes it suitable for pilot-line applications. While not a high-throughput solution, it excels in prototyping and repair—areas where accuracy trumps speed."

Posted: 2 days ago

"Used daily for repairing vintage watch settings. The control is so fine-tuned, I can weld a prong without disturbing the stone. Worth every penny."

Posted: 1 week ago

"Reliable, CE-compliant, and easy to train students on. The compact size is a bonus in crowded lab spaces."

Posted: 3 weeks ago

"Took about two weeks to get comfortable with manual timing and pressure. Now I wouldn’t go back. Just needs better onboarding resources."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.