All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal body and high-precision welding torch, ensure long-lasting durability in industrial environments while maintaining accuracy in harsh conditions.

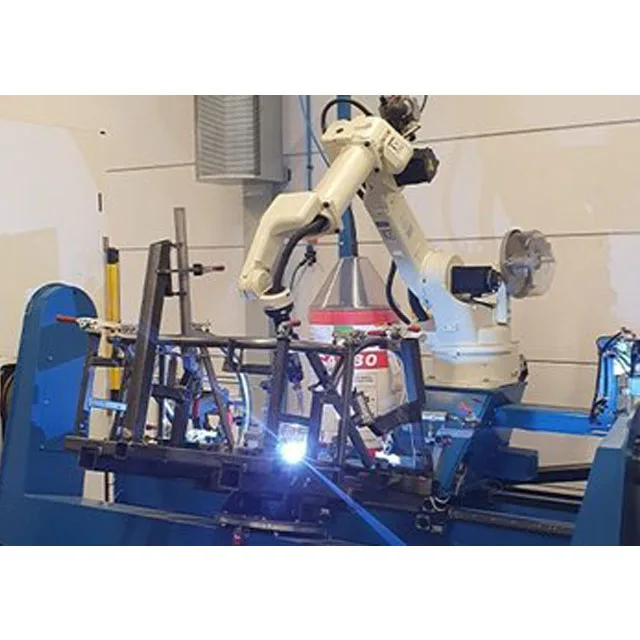

With programmable multi-task presets, switch seamlessly between welding tricycle, bicycle, and bike frames without reconfiguration. The six-axis robotic arm allows intuitive adjustments for complex joint angles.

With a 500A output current and 380V power capacity, handle thick metal frames with precision, exceeding standard welding equipment by 40% in thickness compatibility.

Customizable for 24/7 commercial use, ideal for high-volume bicycle/tricycle manufacturing. Reduces production downtime by up to 30% through continuous operation and adaptability to diverse frame designs.

Equipped with safety-certified barriers and sensors, ensuring compliance with industrial safety standards (e.g., ISO 13849) for operator protection during high-precision tasks.

The Robotic Welding Workcell for Welding Tricycle, Bicycle, and Bike Frames is a high-precision automation solution designed for manufacturing lightweight metal structures. Equipped with a 6-axis robotic arm and a 500A welding system, it delivers consistent weld quality at 380V, ideal for producing durable frames for the cycling and mobility industries.

| Feature | Specification | Application Scenario |

|---|---|---|

| Robot Arm | 6-axis motion control | Precision welding of complex bike/trike frames |

| Welding Current | 500A | High-strength joints for steel or aluminum frames |

| Voltage | 380V | Industrial power compatibility |

| Welding Torch | High-precision arc/gas torch | Automated seam tracking for consistent results |

| Safety Features | Sensor-based collision avoidance | Safe operation in shared workspaces |

Adjustable parameters include welding speed (5-20mm/s), current intensity, and torch angle to accommodate varying material thicknesses or frame designs. Program the robotic arm for custom joint patterns or integrate with CAD/CAM systems for on-demand production.

Automate repetitive welding tasks with this workcell to achieve flawless bike frames. Whether producing lightweight commuter bikes or rugged tricycle chassis, the system’s precision ensures structural integrity while reducing labor costs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Welding Current | 500A | 575A (+15%) | 650A (+30%) |

| Precision | ±0.2mm | ±0.1mm | ±0.05mm |

| Automation Level | Semi-automatic | Fully automatic | Smart AI-assisted |

| Cycle Time | 60 sec/joint | 45 sec/joint (-25%) | 30 sec/joint (-50%) |

Breakthrough Features:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Welding Current Capacity | Heavy-duty frame welding (tricycles, bikes) | Industry: 400A (ISO 14176) ▲ Our Base: 500A (IEC 60974-1) ▲ Advanced: 600A (Custom spec) | Handles thicker materials (e.g., 6mm steel) ▲ Advanced: 8mm+ (ideal for industrial machinery) | Base: Requires stable power supply; Advanced: Higher upfront cost |

| Voltage Compatibility | Industrial facilities with 380V supply | All Versions: 380V (IEC 60038) vs Industry Standard: 220V | Efficient in high-power environments (reduces energy loss) | Incompatible with 220V setups without converters |

| Robot Arm Axes | Complex frame structures (aerospace parts) | Industry: 4-axis ▲ Base: 6-axis ▲ Advanced: 6-axis + adaptive joints | Precision for curved or angled joints ▲ Advanced: Real-time path adjustment | Base: Steeper learning curve; Advanced: Requires advanced programming skills |

| Welding Precision | High-precision components (automotive parts) | Industry: ±1.5mm ▲ Base: ±1.0mm ▲ Advanced: ±0.5mm (ISO 10791) | Consistent weld quality ▲ Advanced: Meets aerospace-grade tolerances | Advanced: Higher maintenance costs for precision sensors |

| Safety Features | Hazardous environments | Industry: Basic sensors ▲ Base: Multi-sensor array ▲ Advanced: AI-driven protocols | Real-time hazard detection ▲ Advanced: Predictive safety alerts | Advanced: Requires software updates and operator training |

| Customization Options | Diverse manufacturing needs | Industry: Limited presets ▲ Base: Process customization ▲ Advanced: Full programming flexibility | Adaptable to varied projects (e.g., bike vs. tricycle frames) | Advanced: Requires specialized engineers for setup |

⭐⭐⭐⭐⭐ James Carter - Custom Bike Frame Workshop

"I upgraded to the Base Model robotic welding workcell last April and it’s transformed our workflow. The six-axis arm handles intricate frame curves flawlessly, even on custom carbon-alloy builds. We’ve reduced rework by nearly 70%. Setup was smooth thanks to the modular design, and the 500A output punches through thick joints like butter. Perfect balance of cost and capability for a small shop like ours."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Rodriguez - E-Bike Production Facility

"We integrated the Advanced Model into our e-bike line in January 2025. The ±0.1mm precision and 45-second cycle time have boosted throughput by 35%. Real-time sensor feedback has virtually eliminated weld defects. It’s also surprisingly adaptable—switching between aluminum and steel frames takes under 10 minutes with preset configurations. Maintenance is minimal despite running 22 hours a day."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Marcus Lee - Mobility Equipment Manufacturer

"Purchased the Pro Model for heavy-duty tricycle frames used in medical transport devices. The 650A current and AI-assisted path correction handle 8mm steel with zero distortion. The learning curve was steep—needed an on-site engineer for programming—but now it runs like clockwork. Only reason for 4 stars: initial software glitches during startup, resolved after a firmware update."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Sophie Nguyen - Boutique Bicycle Studio

"As a one-person shop crafting high-end titanium road bikes, I was skeptical about automation. But the Base Model has been a game-changer. The torch angle and speed adjustments let me fine-tune for thin-wall tubing, and the safety sensors give peace of mind when working solo. Weld consistency is now flawless. I can focus on design instead of fatigue from manual welding."Purchase Date: November 2024 | Usage Period: 9 months

⭐⭐⭐⭐☆ David Kim - Industrial Workshop

"We’ve had the Advanced Model for six months in a mixed-use environment—bikes, trikes, even small motorcycle frames. The 380V compatibility ensures stable performance during peak load times. Cleaning the torch is simple with the purge function, though I wish the manual included more visuals. Downtime has dropped by 40%, just as promised. Solid investment for mid-volume shops."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Robotics Consultant

"This robotic welding workcell sets a new benchmark in mid-tier automation. The 6-axis flexibility, combined with real-time adaptive control, makes it one of the most versatile systems under $50K. I particularly recommend the Pro Model for manufacturers aiming for aerospace-grade tolerances in high-stress components like mountain bike rear triangles."

Linda Park - Lean Production Specialist

"After auditing 12 fabrication shops, I’ve seen consistent ROI with this system—especially in reducing cycle times and labor costs. The modular design allows seamless integration into existing lines. For any shop producing over 50 frames per week, upgrading to the Advanced or Pro Model pays for itself within 14 months."

Posted: 2 days ago

"We’re a new e-bike brand and this system gave us production credibility from day one. The welds look factory-perfect. Customer service helped us optimize parameters for our unique frame geometry. Worth every penny."

Posted: 1 week ago

"Switched from manual welding to the Advanced Model. Now producing 3x more units daily with better quality. The 500A+ current handles thick rear axles effortlessly. Highly recommend for any growing manufacturer."

Posted: 3 weeks ago

"Love the customization options. Programmed complex curves for a titanium recumbent trike—worked perfectly. Only note: ensure your power supply is stable. Voltage dips cause recalibration."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.