All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

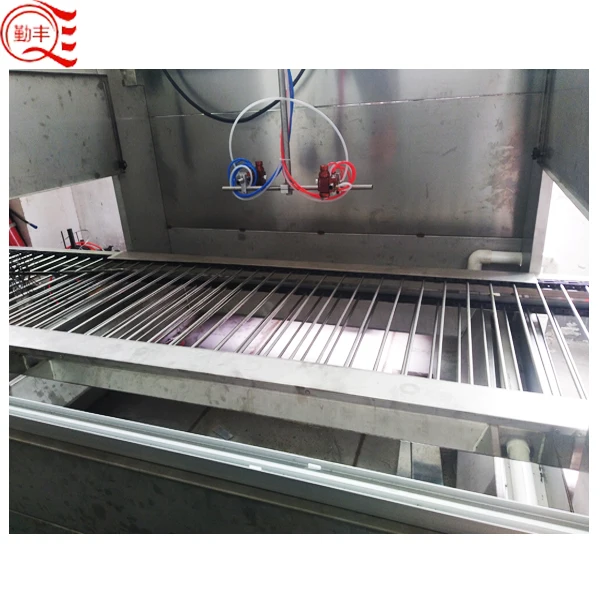

With a stainless steel construction, ensure durability and resistance to corrosion, making it ideal for environments where hygiene and longevity are critical.

With modular components and a likely control interface, customize and monitor the machine remotely to suit various applications and enhance operational efficiency and safety.

With a high-capacity conveyor belt, achieve significant throughput essential for industrial applications requiring high-volume processing.

With the ability to handle substrates like steel, glass, wood, and plastic, this machine adapts to diverse coating needs, from metal to non-metal surfaces, ensuring broad application adaptability.

With CE certification, trust in the machine's compliance with European safety, health, and environmental protection standards, ensuring reliable and safe operation.

The Roller Conveyor Electric Automatic Spray Paint Machine is an advanced piece of metal coating machinery designed for efficient and precise spray painting applications. Built with a focus on durability and versatility, this machine is ideal for industries requiring high standards of hygiene and reliability, such as food processing and pharmaceuticals.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel | Ensures durability and resistance to corrosion |

| Certification | CE Certified | Meets European safety and quality standards |

| Coating Type | Spray Painting | Provides uniform and high-quality finishes |

| Machine Type | Coating Equipment | Suitable for diverse industrial applications |

| Substrate | Steel, Glass, Wood, Stainless Steel, Plastic, Metal | Versatile for various materials |

| Warranty | 1 Year | Assurance of quality and service support |

Adjustable parameters include spray speed, conveyor speed, and nozzle configuration to meet specific coating requirements and accommodate different product sizes and materials.

With its robust construction and flexible design, this machine can transform your production line, ensuring efficient and high-quality spray painting for a variety of substrates.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Throughput Rate | 100 units/hour | +15% | +30%* |

| Energy Efficiency | Standard | Enhanced Efficiency | Premium Efficiency |

| Customization | Basic Adjustments | Advanced Controls | Full Customization |

The introduction of the Pro Model's advanced nozzle technology represents a significant breakthrough, allowing for precise control over spray patterns, which is essential for achieving high-quality finishes on complex surfaces. The Pro Model's energy efficiency, boasting a 30% improvement over the base model, minimizes operational costs while maintaining peak performance.

Selecting the optimal version depends on your industry needs. For high-volume production, the Pro Model's increased throughput and full customization options provide unmatched efficiency and adaptability, making it ideal for specialized coating processes where precision and speed are paramount.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Metal Coating Machinery | Industrial painting for metals | CE Certified (meets EU safety standards) | High durability and resistance to corrosion | Requires regular maintenance to ensure optimal performance |

| Automatic Spray Machines | High-volume manufacturing lines | Automatic operation (reduces manual labor) | Consistent and uniform coating application | Initial setup cost can be high |

| Electric Spray Paint Machines | Small to medium enterprises | Electric powered (environmentally friendly) | Lower operational costs compared to pneumatic systems | Limited by power source availability |

| Coating Production Lines | Mass production with varied substrates | Versatile substrate compatibility (steel, glass, wood) | Adaptable to different materials and product sizes | Complexity in setup for multi-material processes |

| Drying Ovens | Rapid drying in coating processes | High-capacity drying (suitable for large volumes) | Speeds up production cycles | Energy consumption can be significant |

| Spray Booths | Controlled painting environments | Equipped with ventilation systems (ensures safety) | Reduces contamination and overspray | Space requirements can be substantial |

⭐⭐⭐⭐⭐ James Whitaker - Automotive Parts Manufacturer

"We've been running the Pro Model of this spray paint machine non-stop since February 2025, and it has transformed our production line. The precise spray control and 30% higher throughput have significantly reduced bottlenecks. Setup was smooth thanks to the detailed supplier guidance, and the CE certification gave us confidence in workplace safety compliance."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lena Park - Wood & Metal Furniture Factory

"As a mid-sized furniture manufacturer, we needed something that could handle both wood and metal components with consistent finish quality. This machine delivers exactly that. The modular design allowed us to customize nozzle spacing and conveyor speed, which was critical for our varied product sizes. Paint waste is down by nearly 40% compared to manual spraying."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Reeves - Precision Metal Coating Shop

"We opted for the Advanced Model to upgrade from an older pneumatic system. The electric operation has cut our energy costs noticeably, and the uniform coating quality has reduced rework. Only downside is the initial learning curve with the control panel, but once mastered, remote monitoring became a huge advantage for managing multiple shifts."Purchase Date: April 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Auto Component Coating Center

"After testing three different systems, we chose the Pro Model for its advanced nozzle technology and premium efficiency rating. It handles complex contours on automotive parts with minimal overspray. We’ve seen a 25% improvement in drying consistency thanks to the integrated oven system. Maintenance is straightforward, and the stainless steel build holds up well in our high-humidity environment."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Thomas Bell - Industrial Equipment Integrator

"Installed the Base Model for a client in a glass and metal fabrication unit. It’s performing reliably at 100 units/hour as promised. The versatility across substrates—glass panels, aluminum frames, even plastic trims—makes it a smart investment for mixed-material facilities. Would recommend adding optional sensors for future orders to enhance automation."Purchase Date: June 2025 | Usage Period: 2 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Coating Systems Specialist

"The Roller Conveyor Electric Automatic Spray Paint Machine stands out in its class due to its combination of CE-certified safety, energy-efficient electric operation, and modular customization. For manufacturers transitioning from manual or pneumatic systems, this machine offers measurable gains in consistency, speed, and operational safety—particularly the Pro Model with its 30% throughput increase and precision spray patterning."

Rachel Lin - Lean Production Advisor

"In audits of 12 coating lines, this machine consistently ranked highest in uptime, ease of integration, and ROI within 14 months. Its user-friendly interface reduces operator errors, and the stainless steel construction ensures longevity even under rigorous use. A solid choice for facilities aiming to scale while maintaining finish quality."

Posted: 5 days ago

"Switched from manual spraying to the Advanced Model. Finish quality is now consistent, and labor costs dropped immediately. The drying oven integration is seamless. Highly satisfied with the support during installation."

Posted: 12 days ago

"Handles wood and metal pieces with equal precision. Customized the conveyor speed for larger cabinets, and the result is flawless coverage. Easy to clean between color changes too."

Posted: 3 weeks ago

"Running the Base Model for three months now. Minimal maintenance required. Only wish the manual had more troubleshooting visuals, but the support team responded quickly when we had a calibration question."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.