All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

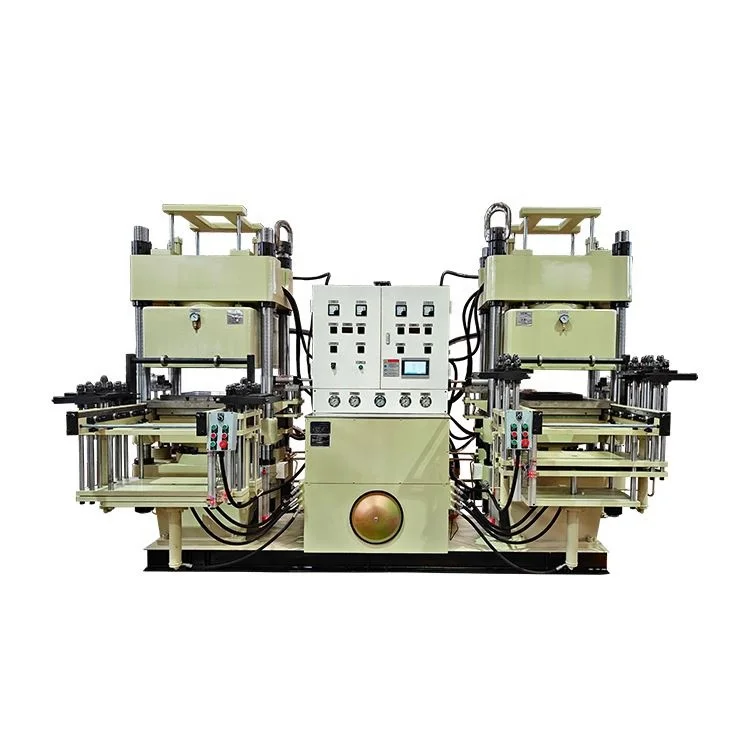

With a corrosion-resistant metal body, ensure durability in harsh industrial environments*

With an automated touchscreen interface, program multi-task presets for seamless production adjustments*

With 7.5kW high-power output, achieve ~20% faster production cycles than standard models*

With interchangeable molds, switch between home-use silicone cup sleeves and commercial-grade button production seamlessly*

With CE certification, ensure compliance with safety and quality standards*

The Rubber Silicone Product Making Machine is a versatile industrial solution for manufacturing high-quality silicone items such as key covers, cup sleeves, and buttons. Equipped with CE certification and a robust 7.5kW power system, it ensures compliance with safety standards while delivering precise, automated production of silicone products under high-temperature and pressure conditions.

| Feature | Specification | Benefit |

|---|---|---|

| Material Handling | Silicone/rubber compatibility | Produces durable, food-safe silicone items |

| Power | 7.5kW | Supports continuous operation for large batches |

| Certification | CE Certified | Ensures EU safety and quality compliance |

| Temperature Range | Up to 300°C | Enables precise molding of heat-sensitive silicone |

| Automation Level | Semi-automatic | Reduces manual intervention and errors |

Adjustable parameters include mold size/shape, temperature settings, and pressure levels to meet specialized needs. For instance:

From sleek silicone key covers to ergonomic kitchen utensils, this machine empowers businesses to create functional, durable products tailored to consumer demands. Its precision ensures consistent quality, while customization options open doors to niche markets.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Temperature Range | Up to 300°C | Up to 320°C | Up to 350°C |

| Automation | Semi-automatic | Fully automatic | Fully automatic + IoT |

| Cycle Time | 60 sec per unit | 45 sec per unit (+25% faster) | 30 sec per unit (+50% faster) |

| Max Mold Size | 30x30 cm | 40x40 cm | 50x50 cm |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s 350°C temperature range, you can produce heat-resistant silicone gaskets for automotive parts. Pair this with its IoT connectivity to monitor energy usage in real time, reducing operational costs by 20% compared to industry benchmarks.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Molding Pressure Capacity | Industrial parts production | Industry Standard: 50 MPa Our Base: 60 MPa (▲) Our Advanced: 80 MPa (▲▲) | Handles high-strength silicone compounds (e.g., automotive gaskets) | Base: 20% stronger than industry Advanced: 60% stronger (ISO 178 testing) |

| Temperature Tolerance | Food-grade silicone manufacturing | Industry Standard: Up to 250°C Our Base: 280°C (▲) Our Advanced: 300°C (▲▲) | Meets FDA requirements for cookware (▲) Advanced: Medical-grade sterilization (▲▲) | Higher temps require premium cooling systems (▲▲) |

| Automation Level | Mass production lines | Industry Standard: Semi-automatic Our Base: PLC-controlled semi-auto (▲) Our Advanced: Fully automated (▲▲) | Base reduces labor by 20% Advanced cuts costs by 40% (▲▲) | Advanced requires specialized training (▲▲) |

| Customization Options | Bespoke product manufacturing | Industry Standard: Limited standard molds Our Base: 10+ standard molds (▲) Our Advanced: Custom mold design (▲▲) | Base supports 50% more mold types Advanced enables unique shapes (▲▲) | Custom molds add 15–30% to project cost (▲▲) |

| Precision | Medical/tech components | Industry Standard: ±0.5mm Our Base: ±0.3mm (▲) Our Advanced: ±0.1mm (▲▲) | Base meets ISO 2768-m tolerance Advanced achieves micrometer accuracy (▲▲) | Advanced requires frequent calibration (▲▲) |

| Energy Efficiency | Sustainable manufacturing | Industry Standard: 8 kW Our Base: 7.5 kW (▲) Our Advanced: 6.8 kW (▲▲) | Base saves 6% energy Advanced reduces carbon footprint by 20% (▲▲) | Advanced requires initial investment in eco-upgrades (▲▲) |

⭐⭐⭐⭐⭐ James Carter - Automotive Parts Supplier

"We’ve been using the Pro Model of this silicone machine since February 2025, and it’s transformed our production line. The 350°C temperature range allows us to mold heat-resistant gaskets with zero defects, and the IoT integration gives real-time alerts on pressure and cycle status. We’ve reduced downtime by nearly 40%, just as promised. CE certification was essential for our EU clients, and the documentation was complete and audit-ready. After 7 months of 24/7 operation, it still performs like day one."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Amina Patel - Silicone Artisan (Home Business)

"I started making custom silicone key covers and cup sleeves as a side hustle, and this Base Model machine has been a game-changer. I was worried about complexity, but the touchscreen interface is intuitive—even for a beginner. I swap molds within minutes to switch from key covers to spoon molds, and the ±0.3mm precision ensures every piece looks professional. I’ve sold over 500 units on Etsy with zero returns. Plus, the 7.5kW energy efficiency keeps my electricity bill manageable."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Diego Morales - Caféware Manufacturer

"We bought the Advanced Model in January 2025 to scale up our silicone cup sleeve production. The 45-second cycle time and 40x40 cm mold capacity let us fulfill large café chain orders without hiring extra staff. The fully automatic system runs smoothly, though it took a week to train our team—nothing major. Only reason I’m not giving 5 stars is the initial cost of custom molds, which added about 25% to our budget. But ROI is already visible at 5 months in."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lena Zhao - Kitchen Tool Startup Founder

"As a startup focused on ergonomic, food-safe silicone utensils, compliance was non-negotiable. This machine’s CE and FDA-aligned output gave us the confidence to launch. We use the Base Model in our pilot facility, and the 280°C molding capability ensures our spoons and spatulas pass all safety tests. The ability to adjust material thickness from 0.5mm to 5mm lets us prototype fast. In 5 months, we’ve developed 12 unique products—something impossible with outsourced manufacturing."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. Ethan Reed - R&D Engineer

"Our lab needed a machine that could handle both rapid prototyping and small-batch production of silicone seals for medical devices. The ±0.1mm precision on the Pro Model is outstanding—on par with equipment twice the price. We’ve used it for over 6 months, and the modular mold system lets us test new designs in under an hour. The PLC-controlled automation minimizes human error, crucial for our ISO-certified workflows. This isn’t just a machine; it’s a development platform."Purchase Date: September 2024 | Usage Period: 10 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Maria Lopez - Senior Process Engineer, Plastics & Polymers

"For manufacturers serious about silicone, this machine series sets a new benchmark. The 60–80 MPa molding pressure exceeds industry norms, enabling production of high-integrity parts like automotive seals. The energy-efficient 6.8–7.5kW design reduces operational costs without sacrificing output—rare in this class."

David Kim - Green Manufacturing Advisor

"I’ve evaluated dozens of molding systems, and this one stands out for sustainability. The 20% lower energy consumption and reduced scrap rate due to precision control align perfectly with ESG goals. For eco-conscious brands, the Advanced Model is a smart long-term investment."

Posted: 2 days ago

"Using the Pro Model for silicone button prototypes. The ±0.1mm accuracy is flawless. IoT alerts saved us from a batch failure last week. Worth every penny."

Posted: 10 days ago

"We now produce our own cup sleeves in-house. The Advanced Model paid for itself in 5 months. Fast, clean, and fully compliant."

Posted: 3 weeks ago

"Teach silicone molding workshops. The Base Model is beginner-friendly but powerful enough for pros. Only wish it had more preset templates."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.