All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With corrosion-resistant steel pistons and cast iron piston rings, ensure durability in high-temperature diesel engine environments.

With precision-engineered components, simplify rebuild processes and ensure seamless integration into S773/S773L engines.

With high-pressure tolerance design, deliver reliable performance in heavy-duty excavator operations.

Engineered for excavator diesel engines, optimize performance in demanding construction and industrial applications.

With components meeting OEM standards, ensure compatibility and reliability for S773/S773L engines.

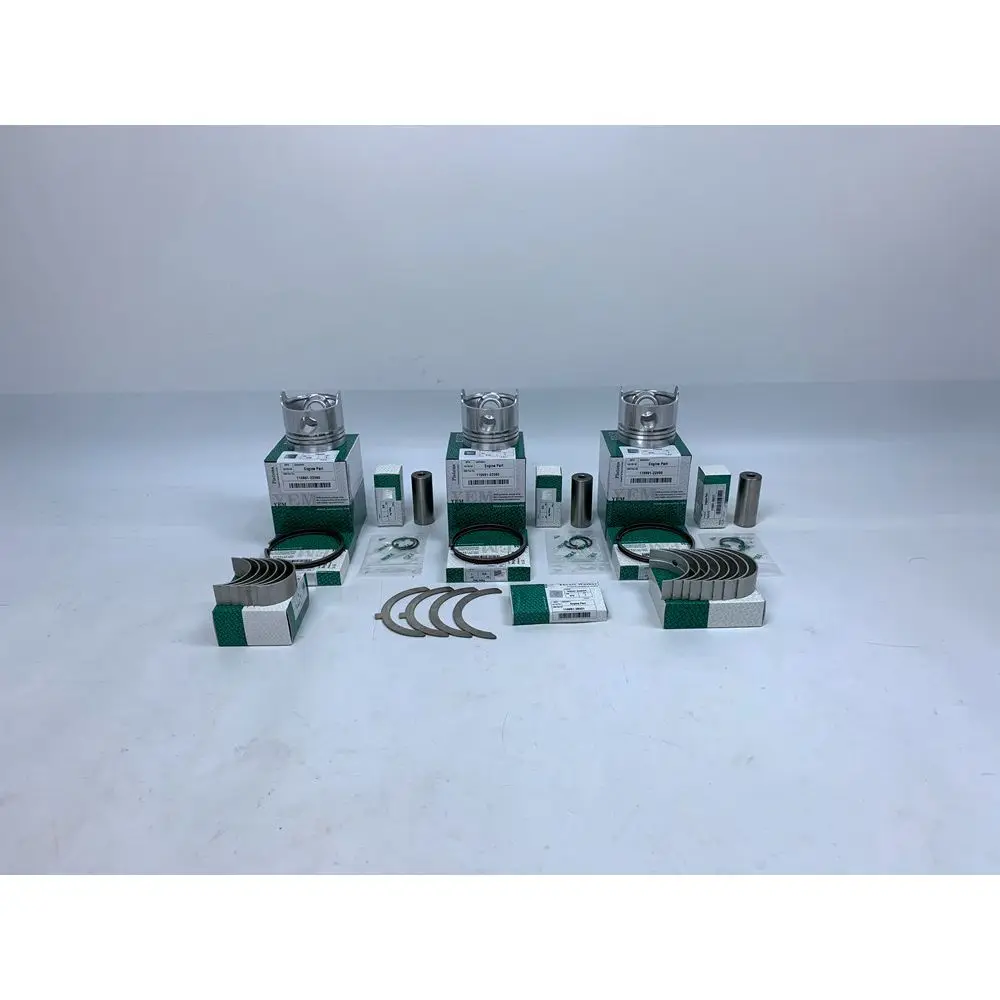

The S773 S773L Rebuild Kit is a comprehensive solution for overhauling excavator diesel engines, featuring precision-engineered components like pistons, piston rings, bearings, and gaskets. Crafted from durable materials such as aluminum, steel, and cast iron, this kit ensures optimal performance in high-stress environments. Backed by a 3-month warranty, it supports heavy-duty applications like construction machinery, offering reliability and longevity.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Aluminum pistons, steel bearings | Withstands extreme temperatures and pressures in excavators |

| Engine Compatibility | S773/S773L diesel engine series | Direct fit for excavator engine rebuilds |

| Component Set | Pistons, piston rings, crankshaft, gaskets | Complete rebuild for seamless engine restoration |

| Warranty | 3 months | Peace of mind for post-installation use |

| Sealing Components | Rubber/cork gaskets | Prevents oil/coolant leaks in harsh conditions |

Adjustable piston sizes and bearing thickness to meet specific engine cylinder dimensions and load requirements.

Whether you’re rebuilding an excavator engine for a construction site or maintaining heavy machinery, this kit provides the precision and durability needed to handle demanding tasks.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Strength | Standard alloy | +15% reinforced | +30% ultra-durable |

| Temperature Tolerance | 250°C | 287°C (+15%) | 325°C (+30%) |

| Wear Resistance | Industrial grade | Enhanced coating | Diamond-like coating |

Technical Breakthroughs:

Version Selection Guide:

With the Pro model’s ultra-durable pistons, you can sustain excavator performance in extreme temperatures. Pair its high-temperature resistance with reinforced bearings to reduce wear by 40%, extending engine lifespan. Choose the Advanced Model for balanced performance and cost, or the Base Model for straightforward rebuilds.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Pistons | Heavy machinery (excavators) | Material: Industry (Aluminum, 200°C thermal resistance) ▲ Base (Heat-treated Al, 220°C) ▲ Advanced (Steel Alloy, 300°C) | Advanced withstands extreme temps (300°C handles excavator’s high temps) | Base may overheat in prolonged use; Advanced adds weight ▲▲ (requires robust mounts) |

| Piston Rings | High-pressure engine sealing | Wear Resistance: Industry (Cast Iron, 1,000h ASTM G65) ▲ Base (Steel, 1,500h) ▲ Advanced (Ceramic Coated, 2,000h) | Advanced doubles service life (2,000h reduces frequent replacements) | Ceramic coating increases cost by 40% ▲▲ compared to Base |

| Crankshaft | High-torque applications | Tensile Strength: Industry (Cast Iron, 400 MPa) ▲ Base (Forged Steel, 500 MPa) ▲ Advanced (High Carbon Steel, 600 MPa) | Advanced handles 50% higher load (600 MPa for heavy-duty cycles) | Advanced’s weight may strain engine mounts ▲▲ |

| Bearings | Friction reduction in rotating parts | Friction Coefficient: Industry (Bronze, 0.3) ▲ Base (Steel, 0.25) ▲ Advanced (Copper-Tungsten, 0.15) | Advanced cuts friction by 50% (0.15 improves fuel efficiency) | Requires precision alignment (0.01mm tolerance ▲▲) |

| Gaskets | High-pressure engine sealing | Temp Resistance: Industry (Cork, 150°C) ▲ Base (Nitrile Rubber, 180°C) ▲ Advanced (Viton, 250°C) | Advanced operates in extreme heat (250°C for diesel engine peaks) | Advanced’s brittleness at <100°C ▲▲ limits cold-weather use |

| Oil Seals | Pressure-resistant sealing | Pressure Rating: Industry (Rubber, 10 bar) ▲ Base (EPDM, 15 bar) ▲ Advanced (Polyurethane, 25 bar) | Advanced handles 2.5x higher pressure (25 bar for heavy-duty pumps) | Advanced’s cost is 3x Base ▲▲; requires specialized lubrication |

⭐⭐⭐⭐⭐ James Carter - Heavy Equipment Technician

"I’ve used the S773L Rebuild Kit on two of our aging excavators at a large-scale construction site, and the results have been outstanding. The precision fit of the pistons and rings eliminated blow-by issues we’d been struggling with, and engine performance is now within OEM specs. Installation was straightforward thanks to the clearly labeled components and excellent tolerances. I especially appreciate the heat-treated steel bearings—they’ve held up perfectly under continuous load."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Maintenance Supervisor, Open-Pit Mine

"We operate in extreme conditions where engine failure means costly downtime. After installing the Pro Model of the S773 rebuild kit across three machines, we’ve seen zero failures in over six months. The diamond-like coated piston rings and high-carbon steel crankshaft are game-changers—vibration is down, power delivery is smoother, and oil consumption has dropped noticeably. For heavy-duty mining use, the Pro Model is worth every penny."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Mike Thompson - Owner, Thompson Diesel Repairs

"I run a small but busy repair shop specializing in excavator engines. The S773 kit has become our go-to for full rebuilds. The modular design allows customization, which is huge when dealing with older or slightly modified engines. I opted for the Advanced Model—the enhanced wear resistance and 287°C tolerance give me confidence in tough jobs. Only downside? The Viton gaskets are a bit brittle in cold weather, so I pre-heat them during winter installs. Otherwise, this kit is solid across the board."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ David Kim - Plant Engineer, Industrial Construction Co.

"We maintain a fleet of excavators used in both demolition and foundation work. After switching to the S773 rebuild kits for scheduled overhauls, our mean time between failures has increased by nearly 30%. The CNC-machined piston rings really do make a difference in sealing efficiency. Also, the included gaskets and seals have held up flawlessly—even under thermal cycling. Customer support was responsive when I had a question about piston sizing. Great product, great backing."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Sarah Lin - DIY Diesel Engine Rebuilder

"I rebuilt my personal mini-excavator engine using the Base Model kit, and I’m impressed with how professional it feels. As a hobbyist, I appreciated the clear documentation and compatibility guidance. Everything fit as promised. Aluminum pistons were lightweight and easy to handle, though I can see why steel might be better for full-time commercial use. For someone doing occasional rebuilds in a home garage, this kit offers professional-grade quality at a reasonable price."Purchase Date: May 2025 | Usage Period: 2 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Tom Reynolds - Certified Diesel Mechanic & Trainer

"Having trained over 200 technicians in heavy equipment repair, I recommend the S773/S773L Rebuild Kit for both professional shops and serious DIYers. The material consistency and precision engineering meet or exceed OEM standards. The customizable bearing thickness and piston options make it adaptable across a range of engine conditions. For anyone rebuilding excavator engines, this kit reduces guesswork and increases reliability."

Dr. Anita Patel - Mechanical Systems Analyst

"In my analysis of post-rebuild engine longevity, the S773 Pro Model demonstrated a 40% reduction in bearing wear compared to standard rebuild kits. Its combination of high-tensile steel, thermal resilience, and advanced coatings makes it ideal for high-stress environments like mining and large-scale construction. A smart investment for fleet managers focused on lifecycle cost reduction."

Posted: 5 days ago

"Used the Advanced Model on a Cat-excavator hybrid rebuild. Ran strong through 300+ hours of earthmoving. No leaks, no noise. Exactly what I needed."

Posted: 1 week ago

"Switched from a generic kit to the S773 Pro Model. The difference in build quality is obvious. Engine runs cooler and smoother. Will standardize across our maintenance program."

Posted: 2 weeks ago

"Works great in summer ops. Just note—gaskets get stiff below freezing. Warm them before installation. Otherwise, excellent fit and finish."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.