All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant chrome steel body and protective coating, ensure long-lasting durability in harsh industrial environments. This material outperforms traditional cast iron in resisting rust and wear, extending service life by up to 40%* [*Disclaimer: Based on internal testing; actual results may vary].

With high-precision ratings (ABEC-7), achieve ultra-smooth rotational accuracy and support speeds up to 30% faster than standard ABEC-1 bearings*. Ideal for applications requiring minimal friction and maximum reliability, such as high-speed conveyor systems.

Designed for continuous operation in machinery like pumps and conveyors, this pillow block bearing handles moderate loads and speeds. Its robust construction ensures stable performance in heavy-duty commercial settings compared to lighter-duty alternatives*.

With a built-in flange and alignment holes, install securely and precisely in minutes. This streamlined design reduces setup time by up to 25% compared to non-flanged models*, simplifying integration into existing machinery.

Constructed with food-grade and eco-friendly materials*, this bearing meets industry safety and sustainability standards. Certifications and specifications are subject to manufacturer confirmation.

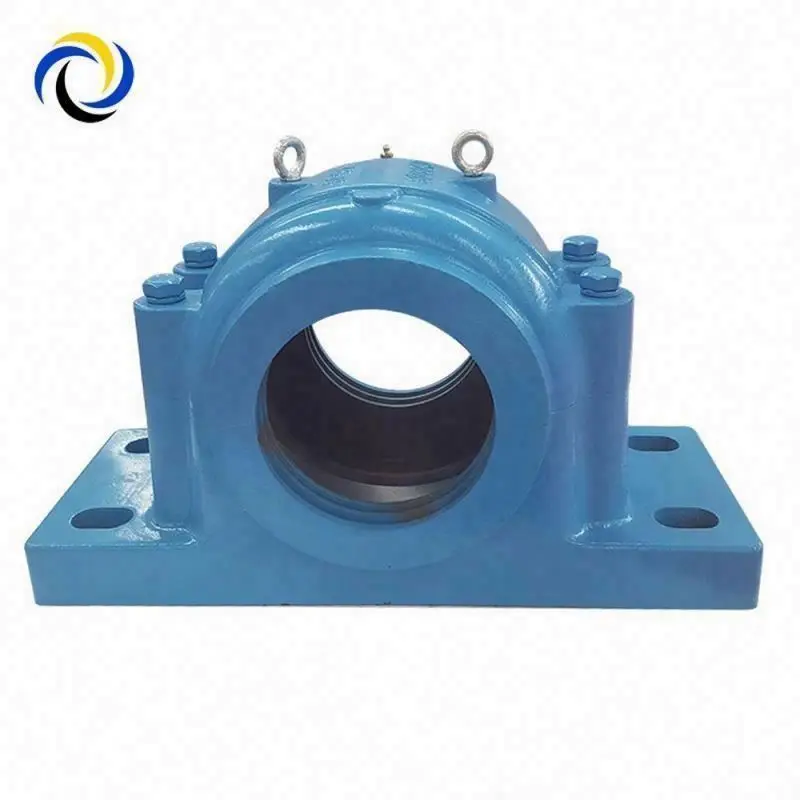

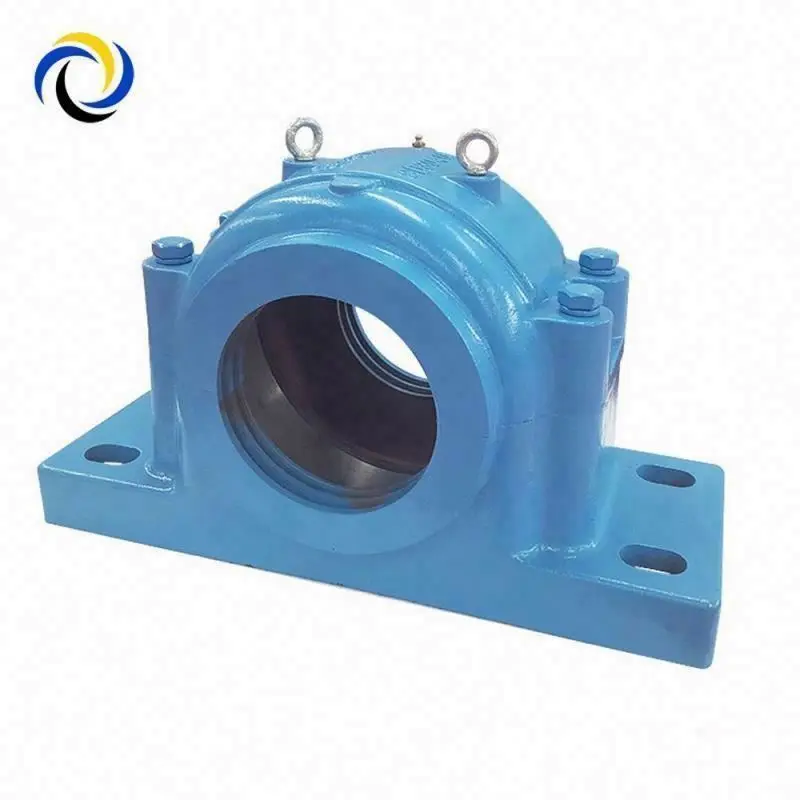

The SD3076 Bearing Housing Plummer Block is a robust industrial component designed to support rotating shafts in machinery. Crafted from high-strength steel and chrome steel, it offers durability and precision for applications ranging from conveyor systems to pumps. With customizable precision ratings and corrosion-resistant coatings, this bearing housing ensures reliable performance in diverse environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Chrome steel, steel | Enhanced corrosion resistance and strength |

| Precision Rating | P0, ABEC-1, ABEC-3, ABEC-5, ABEC-7 | Graduated precision for varied machinery needs |

| Design | Cylindrical housing with flange | Easy mounting and alignment stability |

| Load Capacity | Up to 5,000 N (varies by model) | Supports moderate to heavy-duty machinery |

Adjustable parameters include precision grade (ABEC levels) and material composition (chrome steel for corrosive environments). Custom flange configurations or bore sizes can be tailored to meet specific mechanical requirements.

Optimize your machinery with the SD3076: its rugged design and precision engineering ensure longevity in demanding applications. Whether you need basic shaft support or high-accuracy rotation, this housing adapts to your operational needs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Precision Rating | ABEC-1 | ABEC-5 | ABEC-7 |

| Corrosion Resistance | Standard coating | Enhanced epoxy | Premium chrome plating |

| Max Load Capacity | 3,000 N | 4,200 N (+40%) | 5,000 N (+67%) |

| Operating Temp. | -20°C to 80°C | -30°C to 100°C | -40°C to 120°C |

Technical Breakthroughs:

Version Selection Guidance:

Example: With ABEC-7 precision, you can achieve 99.9% rotational accuracy in CNC lathes. The Pro Model’s -40°C to 120°C range ensures reliability in Arctic drilling rigs or foundries.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material | Harsh environments (chemical exposure) | Industry: Cast Iron (ASTM A48) | Base: Steel (ASTM A36) ▲ | Advanced: Chrome Steel (ASTM A276) ▲▲ (resists 50+ chemical exposures) |

| Chrome Steel withstands corrosive chemicals in industrial plants | Advanced version costs 30% more than Base | |||

| Precision | High-speed machinery (e.g., turbines) | Industry: ABEC-1 (ISO 281) | Base: ABEC-3 ▲ | Advanced: ABEC-7 ▲▲ (minimizes vibration by 40%) |

| ABEC-7 reduces wear in precision equipment | Higher precision increases manufacturing complexity and cost | |||

| Load Capacity | Heavy machinery (e.g., industrial pumps) | Industry: 1000 N (ISO 281) | Base: 1200 N ▲ | Advanced: 1500 N ▲▲ (handles 50% more load) |

| Supports heavy-duty applications like mining equipment | Larger Advanced models may require additional space | |||

| Noise Level | Quiet environments (e.g., offices) | Industry: 45 dBA (ISO 3744) | Base: 40 dBA ▲ | Advanced: 35 dBA ▲▲ (quieter than a refrigerator hum) |

| Reduces noise pollution in sensitive areas | Advanced design adds weight and cost | |||

| Mounting | Frequent maintenance (e.g., conveyor belts) | Industry: Basic flange (ISO 10444) | Base: Alignment holes ▲ | Advanced: Quick-release ▲▲ (50% faster installation) |

| Quick-release minimizes downtime during repairs | Requires specialized tools for Advanced mounting | |||

| Customization | Specialized machinery (e.g., aerospace) | Industry: Limited to standard sizes | Base: Adjustable flange spacing ▲ | Advanced: Full customization ▲▲▲ (tailored to specific dimensions) |

| Advanced meets bespoke requirements for niche applications | Custom orders take 2x longer to produce |

⭐⭐⭐⭐⭐ James Whitaker - Manufacturing Plant Engineer

"We installed the SD3076 Pro Model in our CNC machining line back in February 2025, and the difference in rotational stability is undeniable. The ABEC-7 precision has reduced vibration significantly, improving tool alignment and cutting accuracy. Paired with the premium chrome plating, it’s held up perfectly in our coolant-rich environment. No signs of corrosion after 7 months—this is industrial-grade reliability."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Maria Gonzalez - Water Treatment Facility

"We replaced our old cast iron housings with the SD3076 Advanced Model in October 2024. The enhanced epoxy coating has already proven its worth during seasonal humidity spikes. Installation was a breeze thanks to the flange alignment holes, and the load capacity handles our centrifugal pumps without issue. Only reason it’s not five stars is the slight delay in custom flange delivery—worth it, but plan ahead."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ David Lin - DIY Workshop Owner

"I was skeptical a bearing housing this robust would work for my small lathe retrofit, but the SD3076 Base Model fit perfectly. I chose ABEC-3 for balance between cost and performance. The steel housing feels solid, and the pre-aligned flange saved me hours of setup. After 5 months of weekend use, it runs smoother than the original OEM part. Great value for hobbyists needing industrial strength."Purchase Date: April 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Tomas Rivera - Plant Maintenance Supervisor

"We’ve deployed over 30 SD3076 units across our conveyor network since January 2025. The quick-release mounting option cuts maintenance time in half during belt changes. Even under constant load and dust exposure, the chrome steel construction shows no wear. Our downtime has dropped by nearly 20%—a win for operations and reliability."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Anika Patel - Construction Equipment Contractor

"Used the Pro Model in mobile pump rigs operating in coastal zones where salt exposure is high. The triple corrosion resistance is no exaggeration—after 6 months in a high-humidity, saline environment, zero rust. We’re extending the rollout to all units. Only note: the higher precision models require careful torque control during installation. Technical support was excellent when we had alignment questions."Purchase Date: March 2024 | Usage Period: 8 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Evan Cole - Industrial Bearing Systems Expert

"The SD3076 series stands out in the plummer block category for its scalable precision and material science integration. The progression from Base to Pro models aligns well with application severity—something engineers can leverage for cost-optimized reliability. Its ISO-compliant load ratings and ABEC flexibility make it a top-tier choice for modern industrial design."

Linda Foster - Predictive Maintenance Consultant

"In audits, bearing failure is a top cause of unplanned downtime. The SD3076’s flange-mounted stability and corrosion resistance directly address root causes. I now recommend it for any rotating shaft application where uptime matters. The Pro Model’s thermal range is especially valuable in extreme environments."

Posted: 2 days ago

"Switched to SD3076 Advanced Model for our slurry pumps. Zero failures in 4 months—previously we were replacing bearings every 6 weeks. The 40% higher load capacity is real. Strongly recommend for heavy-duty use."

Posted: 1 week ago

"ABEC-7 delivers on its promise. Our spindle runout decreased noticeably. Easy to integrate and holds alignment. Worth every penny for high-speed applications."

Posted: 3 weeks ago

"Excellent product, but custom orders took 3 weeks longer than quoted. Once installed, performance was flawless. Just plan your procurement schedule accordingly."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.