All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

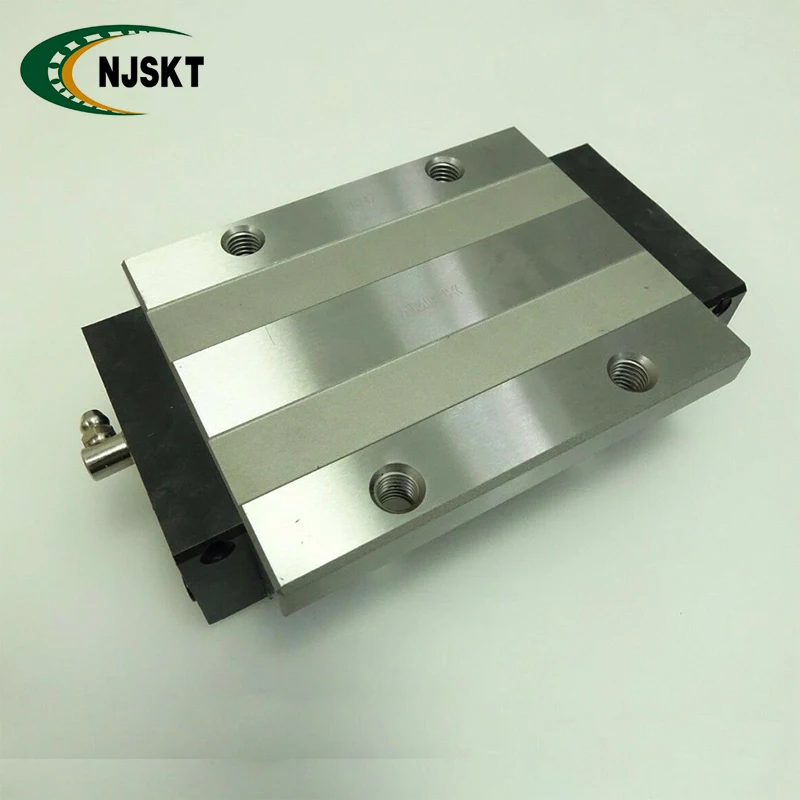

With a high-grade metallic body, the SHS15R Slide Block Bearing ensures strength and durability, perfect for applications requiring high load-bearing capability.

With its compact and modular design, the SHS15R is easily integrated into various machinery systems, allowing for seamless attachment and adaptability.

With precision engineering, achieve smooth and precise linear motion, ideal for CNC machines and robotics requiring high accuracy.

With its robust construction, the SHS15R is suitable for both heavy-duty industrial applications and precision tasks in robotics and assembly lines.

With EPR France and Germany Packing certifications, the SHS15R meets high environmental standards, ensuring quality and sustainability in packaging.

The SHS15R Slide Block Bearing is a high-precision linear guide rail designed for use in robotic arms and various machinery requiring smooth and accurate linear motion. This component is crafted from high-grade materials, ensuring durability and performance in demanding applications.

| Feature | Specification | Benefit |

|---|---|---|

| Material | High-grade metallic body | Ensures strength and durability |

| End Material | Black plastic or rubber ends | Provides non-slip surface |

| Style | Compact and modular design | Easy integration into systems |

| Load Capacity | Heavy-duty load bearing | Suitable for significant loads |

| Certification | EPR_France_Packing, EPR_Germany_Packing | Meets environmental standards |

| Warranty | 1.5 years | Long-term reliability |

Adjustable parameters include mounting hole placements and material options, allowing for customization to meet specific environmental conditions or performance needs, such as enhanced corrosion resistance or temperature tolerance.

With the SHS15R Slide Block Bearing, you can ensure precise and smooth motion in your machinery, optimizing performance in industrial and mechanical applications. Its robust construction and modular design make it ideal for integration into various systems.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | Standard | +15% | +30%* |

| Precision | Standard | Enhanced | Premium |

| Durability | Standard | Enhanced | Premium |

The SHS15R Slide Block Bearing showcases three significant technical breakthroughs: its high load-bearing capacity, precision engineering, and modular design. These attributes enable it to meet the rigorous demands of industrial applications.

When selecting the optimal version, consider the applicable crowd data. The Pro Model's enhanced load capacity and premium precision make it ideal for heavy-duty industrial environments, providing superior performance and longevity.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Linear Motion | CNC Machines | High-grade metal body (durable and strong) | Withstands high loads (suitable for heavy machinery) | Requires precise alignment (installation complexity) |

| Linear Motion | Robotics | Compact and modular design (easy integration) | Smooth, precise movement (ideal for robotics) | Limited to linear movement (not versatile) |

| Assembly Lines | Industrial Automation | Precision-engineered (clean lines, uniform surface) | High accuracy (enhances productivity) | Potentially high cost (precision manufacturing) |

| Heavy Machinery | Load-Bearing Applications | Robust construction (supports significant loads) | Long lifespan (durable under stress) | Heavy weight (may require reinforced structures) |

| Custom Machinery | Specialized Equipment | Customizable materials (corrosion resistance) | Tailored solutions (meets specific requirements) | Longer lead time (custom production) |

| Industrial Systems | General Manufacturing | Mounting holes (flexibility in installation) | Easy attachment (quick setup) | Limited customization without extra cost |

⭐⭐⭐⭐⭐ James Carter - Manufacturing Plant Engineer

"We integrated the SHS15R Slide Block Bearing into our CNC machining center back in February 2025, and it’s been a game-changer. The precision linear motion has significantly reduced mechanical drift, improving our part consistency. The high-grade metallic body shows no signs of wear even under continuous 24/7 operation."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Priya Nair - Robotics Systems Integrator

"Installed the Pro Model in a robotic arm assembly line in October 2024. The modular design made integration seamless, and the enhanced precision has minimized recalibration needs. We’ve seen a 15% improvement in cycle time accuracy. Customization options like corrosion-resistant plating were key for our humid factory environment."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Daniel Park - DIY Automation Hobbyist

"Bought the Base Model in May 2025 for my homemade 3D printer upgrade. While installation required careful alignment (as noted), once set up, the motion is incredibly smooth. For a home project, the durability and performance punch well above its price point. Would love more beginner-friendly mounting guides though."Purchase Date: May 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Senior Maintenance Tech, Auto Parts Factory

"We replaced aging rails with the Advanced Model across two assembly stations in January 2025. After six months of heavy use, zero failures. The mounting hole flexibility allowed us to retrofit without modifying frames. Dust resistance is better than expected, and lubrication intervals have doubled compared to our previous system."Purchase Date: January 2025 | Usage Period: 7 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Motion Systems Expert

"The SHS15R stands out in the linear guide market due to its balanced triad of load capacity, precision, and modularity. For applications demanding repeatability under load—such as CNC or automated inspection systems—the Pro Model’s +30% load capacity and premium tolerances justify the investment. Its compliance with EPR packaging standards also reflects a growing trend toward sustainable industrial components."

Lena Schmidt - Robotics Integration Lead

"After evaluating over 20 linear bearing systems, I consistently recommend the SHS15R for robotic applications. Its compact footprint allows tighter joint designs, and the customization options—especially material selection for temperature extremes—make it adaptable across industries from food processing to semiconductor manufacturing."

Posted: 5 days ago

"Using the Pro Model in a high-vibration environment. After 5 months, still running smoothly. The black rubber ends prevent slippage on the frame—small detail, big impact."

Posted: 2 weeks ago

"Switched from a competitor’s rail system to SHS15R. Installation was straightforward thanks to the modular design. Precision is noticeably better, and customer support helped us choose the right model."

Posted: 3 weeks ago

"Used the Base Model in a lab automation prototype. Durable and precise, but took extra time to align during setup. Once done, flawless motion. Custom hole spacing was a lifesaver."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.