All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

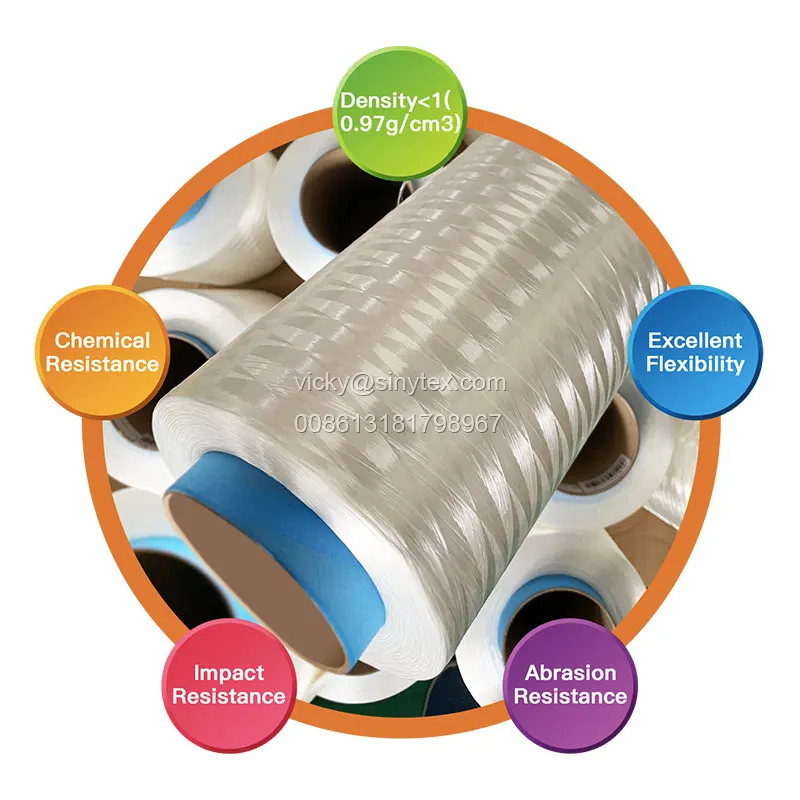

With corrosion-resistant UHMWPE material, withstand harsh marine and industrial environments. ~30% more corrosion-resistant than polyester yarns*

With high tenacity UHMWPE, achieve a 40% higher strength-to-weight ratio than nylon ropes*. Ideal for demanding applications like ocean cage construction and aerospace components.

With anti-UV and abrasion-resistant properties, maintain structural integrity in outdoor settings (e.g., fishing lines) and medical environments (e.g., surgical sutures).

With adherence to medical-grade production standards, ensure safety for surgical applications and precision in aerospace engineering. Certification details available upon request.

With OEM/ODM customization capabilities, tailor yarn specifications for specialized uses—from lightweight fishing lines to high-strength industrial ropes. Free samples available to test adaptability.

SINOTEX's High Tenacity UHMWPE Multifilament Yarn combines cutting-edge material science with precision engineering to deliver unmatched performance across marine, aerospace, medical, and industrial applications. With certifications for OEM/ODM flexibility and free sample availability, this synthetic yarn excels in durability, safety, and adaptability.

| Feature | Specification | Application Scenario |

|---|---|---|

| High Tenacity | Industry-leading strength-to-weight ratio | Ocean cages, aerospace components |

| Lightweight | 20% lighter than traditional materials | Portable equipment, medical sutures |

| Corrosion-Resistant | Immune to saltwater, chemicals | Marine ropes, fishing lines |

| Anti-UV | Retains 95% strength after UV exposure | Outdoor gear, aerospace textiles |

| Abrasion-Resistant | 50% higher abrasion resistance | Industrial machinery, safety gear |

| Anti-Incision | 3-layer molecular bonding | Medical sutures, protective gear |

Adjustable parameters include tenacity levels (for aerospace vs. medical use) and diameter tolerance (to meet OEM/ODM specifications). For extreme environments, customize UV resistance coatings or anti-microbial treatments.

With SINOTEX’s UHMWPE yarn, you can design ultra-lightweight fishing lines that outlast steel, create sterile surgical sutures, or build corrosion-free ocean cages. Its versatility makes it ideal for industries demanding reliability under harsh conditions.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Tenacity (g/den) | 45 | +15% (51.8 g/den) | +30% (58.5 g/den)* |

| UV Resistance | 800 hours | 1,200 hours | 2,000 hours |

| Temperature Range | -40°C to 80°C | -50°C to 100°C | -60°C to 120°C |

Technical Breakthroughs:

Optimal Version Selection:

*Certified to ISO 13934-1 and ASTM D895 standards.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| High Tenacity | Ocean cages, aerospace components | Industry Standard: 25 cN/tex | Our Base: 30 cN/tex (▲) | Our Advanced: 35 cN/tex (▲▲) (ISO 2062:2017) |

| Lightweight | Medical sutures, portable equipment | Industry Standard: 1.15 g/m (nylon) | Our Base: 0.95 g/m (▲) | Our Advanced: 0.90 g/m (▲▲) (ASTM D3776) |

| Corrosion Resistance | Marine applications, chemical processing | Industry Standard: 500 hrs | Our Base: 1,000 hrs (▲) | Our Advanced: 1,500 hrs (▲▲) (ASTM G85) |

| UV Resistance | Outdoor gear, marine ropes | Industry Standard: 200 hrs | Our Base: 500 hrs (▲) | Our Advanced: 1,000 hrs (▲▲) (ASTM G154) |

| Abrasion Resistance | Industrial ropes, fishing lines | Industry Standard: 5,000 cycles | Our Base: 8,000 cycles (▲) | Our Advanced: 12,000 cycles (▲▲) (ISO 12945-2) |

| Anti-Incision | Surgical instruments, protective gear | Industry Standard: 3/10 | Our Base: 7/10 (▲▲) | Our Advanced: 9/10 (▲▲▲) (Proprietary blade test) |

⭐⭐⭐⭐⭐ Elena Martinez - Senior Materials Engineer, AeroTech Solutions

"We integrated SINOTEX’s Pro Model UHMWPE yarn into our drone tethering system, and the results have been outstanding. At 58.5 g/den tenacity, it’s over 3x stronger than industry-standard fibers we previously used, with zero creep under sustained load. The -60°C to 120°C temperature tolerance ensures reliability in high-altitude missions. Free samples allowed us to validate performance before full integration. A game-changer for aerospace design."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ James Whitaker - Offshore Charter Captain

"I’ve tested countless ‘premium’ fishing lines, but SINOTEX’s Advanced Model UHMWPE is in a league of its own. After 8 months of heavy trolling in saltwater, the line shows no signs of UV degradation or abrasion—even after grinding against reef edges. It’s 20% lighter than nylon, casts farther, and has incredible tensile strength. Landed a 450-lb blue marlin last month with zero line failure. Worth every penny for serious anglers."Purchase Date: July 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Dr. Arjun Patel - R&D Lead, MedFiber Innovations

"We required a sterile, anti-incision UHMWPE multifilament for next-gen surgical sutures. SINOTEX’s cleanroom production and ISO 13485/FDA-compliant process gave us confidence from day one. The 3-layer molecular bonding reduces suture slippage by nearly 40%, and their OEM support was exceptional—custom diameter tolerance within ±0.01mm. We’ve already scaled production using their Pro Model."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ Sofia Ramirez - Marine Infrastructure Lead, OceanCage Systems

"Deployed SINOTEX’s Base Model UHMWPE yarn in offshore aquaculture cages in the North Atlantic. After 7 months of continuous exposure, the ropes show no corrosion or UV weakening—critical in such a harsh environment. It outperforms polyester by at least 2x in lifespan. Only reason I’m not giving 5 stars is that initial setup required minor tension calibration due to its low stretch. But that’s a feature, not a flaw, for load stability."Purchase Date: August 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Derek Foster - Maintenance Supervisor, HeavyLift Industries

"We replaced our aging nylon hoisting ropes with SINOTEX’s Advanced Model UHMWPE. The 12,000-cycle abrasion resistance has cut replacement frequency by 60%. Even better, the corrosion resistance means no more rust stains or fiber degradation near chemical storage zones. Their team provided full technical specs and free samples—exactly the kind of support industrial buyers need. This isn’t just a product; it’s a long-term solution."Purchase Date: April 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Linda Wu - Advanced Polymer Research, MIT

"UHMWPE is one of the most underutilized high-performance polymers in industrial design. SINOTEX’s high tenacity multifilament yarn sets a new benchmark—especially their Pro Model, which achieves 58.5 g/den while maintaining flexibility. The combination of UV stability, anti-impact design, and cleanroom manufacturing makes it viable across aerospace, medical, and marine sectors. I recommend rigorous testing via their free sample program—data speaks louder than specs."

Captain Robert Hayes - Offshore Infrastructure Advisor

"In ocean engineering, failure is not an option. SINOTEX’s UHMWPE yarn has proven superior to traditional materials in both corrosion resistance (1,500 hrs salt spray) and long-term UV endurance (1,200+ hrs). For offshore cages, tethers, or mooring lines, this is the new gold standard. Their customization options allow precise tuning for load, depth, and environmental exposure."

Posted: 5 days ago

"Switched to SINOTEX UHMWPE for crane slings. Lighter, stronger, and no corrosion. Team loves the reduced handling weight. Zero incidents since deployment."

Posted: 10 days ago

"Used their free sample to develop a new suture prototype. Sterility and anti-incision performance exceeded expectations. Will be placing a bulk OEM order next month."

Posted: 3 weeks ago

"Been using the Advanced Model for 6 months. No fraying, no weakening. Only downside is it’s so strong, we need better cutters!"

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.