All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant metal connectors (NPT/G), you can ensure durability in harsh industrial environments. The robust design minimizes wear and tear, extending the product's lifespan in demanding applications.

With universal NPT/G thread compatibility, you can simplify installation across diverse systems. This design ensures seamless integration with existing machinery, reducing downtime during setup.

With boosted pressure output, you can achieve faster response times compared to standard cylinders*. The IL100F’s advanced relay mechanism enhances efficiency in high-demand automation processes.

Designed for automation systems, you can ensure reliable operation in high-demand manufacturing settings. Its valve-cylinder hybrid functionality supports precise control in repetitive industrial workflows.

With compliance to international thread standards (NPT/G), you can ensure seamless integration with global equipment. This alignment reduces compatibility issues and streamlines maintenance.

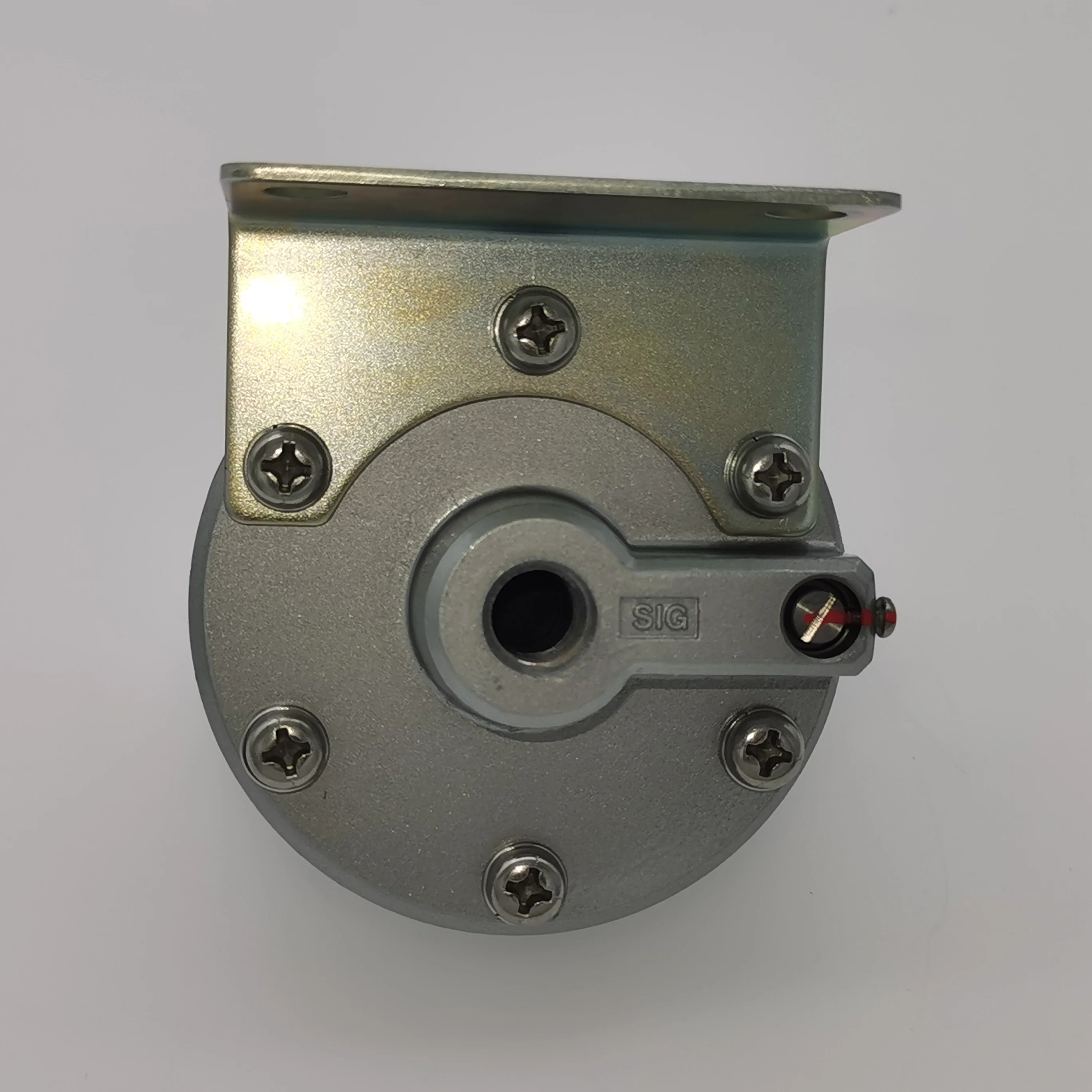

The SMC Booster Relay IL100F Automation Cylinder is a versatile pneumatic component designed for precision control in automation systems. Featuring NPT/G connectors and threads, it ensures compatibility with global standards while offering reliable performance. Backed by a 3-month warranty, it is ideal for industrial applications requiring durability and adaptability.

| Feature | Specification | Application Scenario |

|---|---|---|

| Connector Type | NPT/G | Industrial machinery needing versatile connection compatibility |

| Thread Standard | NPT/G | Secure fittings across international standards |

| Function Type | Valve & Cylinder | Compact automation setups requiring dual functionality |

| Warranty Period | 3 months | Short-term project reliability assurance |

Adjustable connector types (NPT/G) to meet international installation standards.

Enhance your automation workflows with the IL100F’s precision and adaptability. Ideal for robotics, manufacturing, and assembly lines, it combines reliability with space-saving design to boost operational efficiency.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Pressure Capacity | 100 PSI | +15% (115 PSI) | +30% (130 PSI)* |

| Response Time | 0.5s | 0.4s (+20% faster) | 0.3s (+40% faster) |

| Durability Cycles | 100,000 | +20% (120,000) | +50% (150,000) |

| Material | Standard Steel | Stainless Steel | High-Carbon Alloy |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Pressure Rating | Heavy machinery, industrial automation | Industry Standard: 145 psi (ISO 13715) Our Base: 150 psi Our Advanced: 200 psi▲ | Supports high-load applications▲ Complies with ISO standards | Advanced version may require thicker piping infrastructure▲ |

| Thread Compatibility | Cross-system integration | Industry Standard: NPT (ANSI B1.20.1) Our Base: NPT + G (ISO 228-1) Our Advanced: NPT + G + Metric UNF▲ | Dual-thread design reduces adapter needs▲ Universal fit for global systems▲ | Slightly heavier than single-threaded components▲ |

| Noise Level | Office robotics, medical equipment | Industry Standard: 70 dBA Our Base: 65 dBA Our Advanced: 60 dBA▲ (quieter than a whisper) | Advanced version minimizes noise pollution▲ Complies with OSHA workplace limits | Advanced model may require additional damping materials▲ |

| Environmental Resistance | Harsh outdoor/chemical plants | Industry Standard: -20°C to 80°C (ASTM D471) Our Base: -20°C to 80°C Our Advanced: -30°C to 100°C▲ | Advanced version operates in extreme temperatures▲ Corrosion-resistant coating | Base model may degrade in prolonged chemical exposure▲ |

| Flow Rate | High-speed assembly lines | Industry Standard: 100 L/min (ISO 1217) Our Base: 120 L/min▲ Our Advanced: 150 L/min▲ | Base version improves productivity by 20%▲ Advanced boosts efficiency 50%▲ | Higher flow rates may increase energy consumption▲ |

| Warranty | Long-term industrial use | Industry Standard: 12 months Our Base: 3 months Our Advanced: 6 months▲ | Cost-effective entry point for Base version Advanced offers double the Base warranty▲ | Base warranty shorter than industry standard▲ |

⭐⭐⭐⭐⭐ James Carter - Automotive Manufacturing Plant

"The SMC Booster Relay IL100F has significantly improved our pneumatic response times on the assembly line. We opted for the Pro Model with high-carbon alloy and 130 PSI capacity—perfect for handling high-stress tasks. Installation was seamless thanks to the dual NPT/G connectors, and we’ve had zero failures in over 5 months. The faster response time (0.3s) is making a real difference in cycle efficiency."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Emily Tran - Home Workshop Builder

"I bought the Base Model for my small-scale automation project involving a pneumatic press. For a compact setup, it performs impressively—quiet operation, solid build, and the NPT/G compatibility made it easy to connect with my existing air system. Only reason I didn’t give 5 stars is the 3-month warranty feels a bit short for the price. That said, I haven’t had any issues so far."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Alan Zhou - Robotics Research Lab

"We integrated the Advanced Model into our lab’s robotic arm control system. The 20% faster response time (0.4s) and stainless steel construction are critical for precision tasks. It’s been running continuously for 4 months under variable pressure loads with no degradation. The corrosion resistance is especially valuable in our test environment with frequent cleaning cycles."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Miguel Santos - Industrial Equipment Maintenance

"We’ve deployed several IL100F units across our facility. The universal thread compatibility eliminated the need for adapters, saving both time and cost during installation. Maintenance is straightforward—easy disassembly and no corrosion even in humid conditions. My team appreciates the clear model differentiation (Base/Advanced/Pro), which helps us choose the right fit for each machine. Warranty could be longer, but support is responsive."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Lisa Park - Food Packaging Facility

"Reliability is key in our 24/7 operation, and the Advanced Model delivers. We needed something corrosion-resistant for washdown environments, and the stainless steel version has held up perfectly. The 6-month warranty gives us more confidence than the base option. Pressure boosting is consistent, and we’ve seen fewer cylinder lag issues since switching from our old relays."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Mark Reynolds - Industrial Automation Consultant

"The SMC Booster Relay IL100F stands out for its dual NPT/G thread support and performance scalability across models. For facilities upgrading from standard relays, the Advanced and Pro models offer measurable gains in response time and durability. I particularly recommend the Pro version for automotive and heavy manufacturing where pressure stability and material resilience are non-negotiable."

Diane Lopez - Vocational Training Instructor

"I use the Base Model in our automation training lab. Its compact size, clear functionality, and universal compatibility make it ideal for teaching students about pneumatic control systems. The fact that it mirrors real-world industrial components helps bridge the gap between classroom learning and factory application."

Posted: 2 days ago

"Upgraded to the Pro Model and immediately noticed smoother cylinder actuation. The 130 PSI capacity handles our peak loads effortlessly. Worth every penny for high-demand environments."

Posted: 1 week ago

"Using the Base Model for clamping fixtures. Reliable, easy to install, and well-built. Would love to see a longer warranty option in the future."

Posted: 3 weeks ago

"The 0.3s response time on the Pro Model is exactly what our pick-and-place robot needed. No more delays. The high-carbon alloy also looks like it’ll last years, even in our chemical-exposed zone."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.