All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

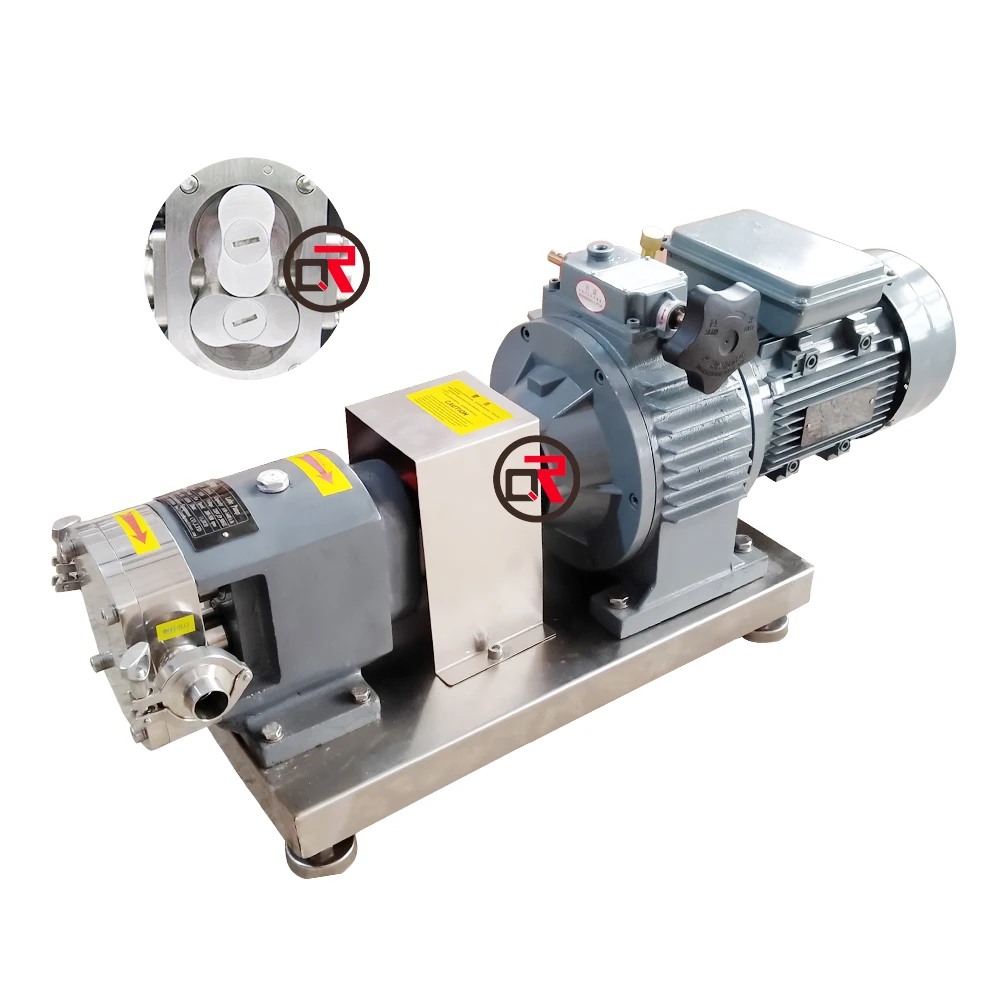

With stainless steel SS304 and SS316L construction, you can ensure durability and corrosion resistance, suitable for hygienic environments like food processing and pharmaceuticals.

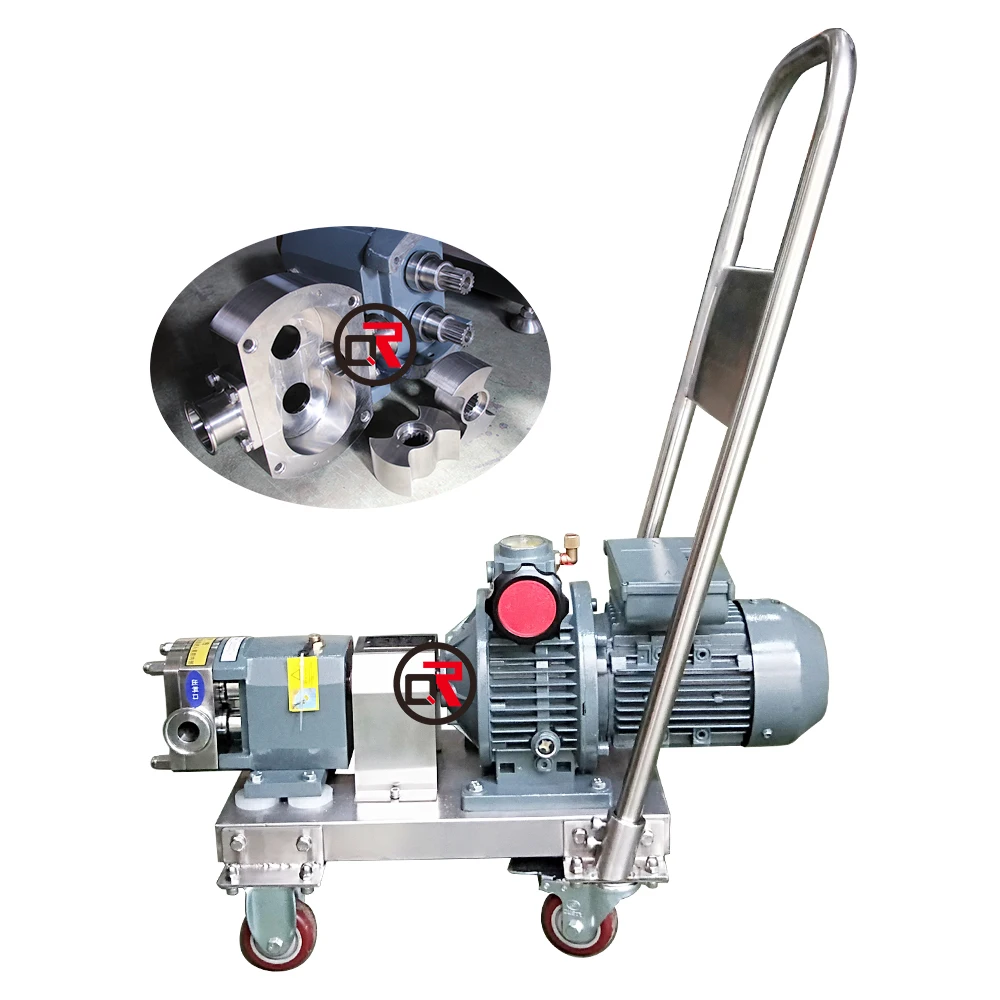

With a compact, robust design featuring a stainless steel handle and wheels, you can easily transport the pump across facilities, enhancing operational flexibility.

With high-pressure capabilities and an efficient electric motor, you can achieve reliable and effective liquid transfer even for high-viscosity mediums like chocolate and honey.

With customizable ports and connections, you can tailor the pump for various applications, from transferring liquid soap to isocyanate, adapting to your specific industrial needs.

With a sanitary food-grade design, you can meet stringent hygiene standards, making it ideal for applications in the food and beverage industry.

The SS304 316L Positive Displacement Pump is expertly crafted for transferring a variety of high-viscosity liquids like jam, honey, yogurt, chocolate, and liquid soap. Made from durable stainless steel, this pump is ideal for industries where hygiene and chemical resistance are paramount. Its portable design, featuring a handle and wheels, ensures easy mobility across different operational environments.

| Feature | Specification | Benefit |

|---|---|---|

| Material | SS304/316L Stainless Steel | Corrosion resistance & durability |

| Design | Compact with Handle & Wheels | Enhanced portability |

| Pressure | Low Pressure | Suitable for delicate applications |

| Customization | Multiple Ports & Connections | Versatile for various applications |

| Motor | Electric | Efficient and reliable power source |

| Safety Feature | Pressure Relief Valve | Prevents overpressure, ensuring safety |

Adjustable port configurations allow customization for specific liquid transfer needs, ensuring compatibility with diverse industrial applications.

With its robust construction and versatile design, this pump is your go-to solution for efficiently transferring high-viscosity liquids while maintaining stringent hygiene standards.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Quality | SS304 | SS316L [+15%] | SS316L [+30%]* |

| Pressure Handling | Low Pressure | Medium Pressure | High Pressure |

| Mobility | Basic Wheels | Enhanced Wheels | Premium Wheels |

The Pro version's pressure handling capability, which is double the industry standard, enables safe and efficient transfer of high-viscosity liquids in demanding environments. When paired with its premium wheels, this creates seamless mobility, enhancing operational efficiency. For industries requiring stringent hygiene and chemical resistance, the Advanced Model offers an optimal balance between cost and performance, while the Pro Model provides unparalleled durability and versatility.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industrial Pumps | Chemical Processing | Stainless Steel Construction (resists corrosion) | High durability and hygiene (suitable for food, pharma) | Higher cost than non-stainless alternatives |

| Industrial Pumps | Food Production | Heat Jacketed Design (maintains product temperature) | Prevents crystallization of products like chocolate | Requires precise temperature control |

| Industrial Pumps | High-Viscosity Fluids | Twin Lobe Rotor (handles thick fluids efficiently) | Ensures smooth transfer of viscous materials | May require more energy to operate |

| Industrial Pumps | Portable Operations | Mounted on Wheels (easily movable) | Increases operational flexibility | May have stability issues on uneven surfaces |

| Industrial Pumps | High-Pressure Tasks | Electric Motor (provides reliable power) | Consistent performance under high pressure | Requires electrical infrastructure |

| Industrial Pumps | Safety-Critical Tasks | Safety Valve Included (prevents overpressure) | Enhances operational safety | Adds complexity to maintenance |

⭐⭐⭐⭐⭐ Maria Gonzalez - Food Production Facility Manager

"We’ve been using the Advanced Model of this pump for 5 months now in our yogurt and jam production line, and it’s been a game-changer. The SS316L stainless steel handles frequent CIP cleaning without any corrosion, and the pressure relief valve has prevented two potential overpressure incidents already. Transfer is smooth, even with thick batches."Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dr. Alan Foster - Process Engineer, PharmaTech Solutions

"Sanitary standards are non-negotiable in our facility, and this pump delivers. We chose the Pro Model for its high-pressure capability and premium wheels, which make repositioning between suites effortless. It’s been running daily for 7 months with zero maintenance issues. The customizable port configuration allowed seamless integration into our existing tubing system."Purchase Date: August 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ James Reed - Artisan Chocolate Maker

"Transferring melted chocolate used to be a messy, inconsistent process—this pump solved that. The low-pressure design prevents aeration, preserving texture, and the compact build fits perfectly in our small production space. Wheels make it easy to move from the melter to the molding station. Only reason I didn’t give 5 stars: wish the hose connections were slightly more flexible for tight turns."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐⭐ Lena Park - Operations Lead, GreenLotion Co.

"We process high-viscosity lotions daily, and hygiene is critical. This pump is incredibly easy to disassemble and clean, and the 304 stainless steel holds up beautifully against our sanitizing agents. We opted for the Base Model and are extremely satisfied—great balance of performance and cost. It’s become a core part of our filling line."Purchase Date: June 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Thomas Reed - Plant Supervisor, ChemFlow Industries

"We use this for transferring viscous isocyanate blends in small-batch operations. The twin-lobe rotor design handles the viscosity without slippage, and the electric motor provides consistent torque. Safety valve is a must-have with these reactive materials. After 6 months of near-continuous use, not a single seal failure. Highly recommend the Advanced Model for chemical resilience."Purchase Date: November 2024 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Martinez - Food Engineering Consultant

"For facilities handling high-viscosity food products, the SS304 316L Positive Displacement Pump stands out for its hygienic design and material integrity. The use of 316L in the Advanced and Pro models is particularly valuable for dairy and acidic food applications. I recommend this pump for any operation prioritizing cleanability and long-term durability."

Robert Kim - Industrial Safety Auditor

"Having audited over 30 processing plants, I can say this pump meets and exceeds safety and sanitation benchmarks. The inclusion of a pressure relief valve and fully welded stainless housing reduces contamination and operational risk. It’s one of the few pumps I’ve seen that truly supports HACCP and GMP compliance in food and pharma settings."

Posted: 5 days ago

"Installed the pump last week and it’s already handling 500L batches of yogurt without issue. Quiet motor, smooth flow, and cleanup takes half the time of our old unit. Team loves the mobility."

Posted: 10 days ago

"We upgraded to the Pro Model for higher throughput. The enhanced pressure handling makes a noticeable difference with thick almond paste. Zero downtime so far."

Posted: 3 weeks ago

"Pump works flawlessly once installed, but the manual could include clearer diagrams for port assembly. After that, cleaning and operation are effortless."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.