All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With Q235 steel construction, ensure durability in harsh environments, outperforming traditional models using lesser-grade materials.*

With modular connectors, assemble structures rapidly compared to non-modular frames.*

With a rigid rectangular frame design, maintain stability under heavy loads exceeding flimsier alternatives.*

With modular adaptability, deploy in diverse settings—from construction sites to warehouses—expanding usability beyond single-purpose frames.*

With compliance to industrial safety standards, prioritize worker safety in line with regulated construction practices.*

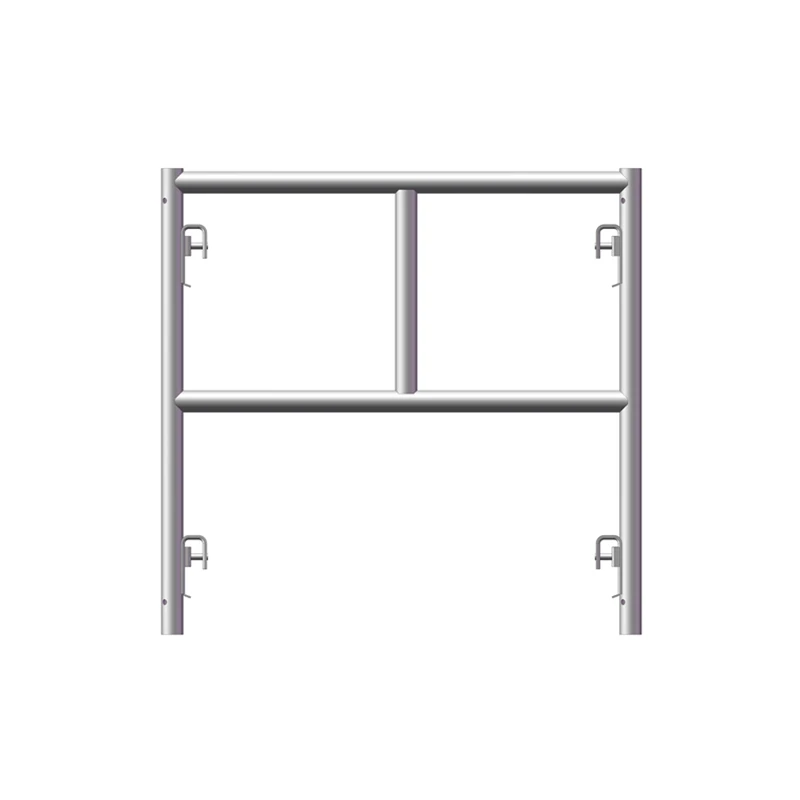

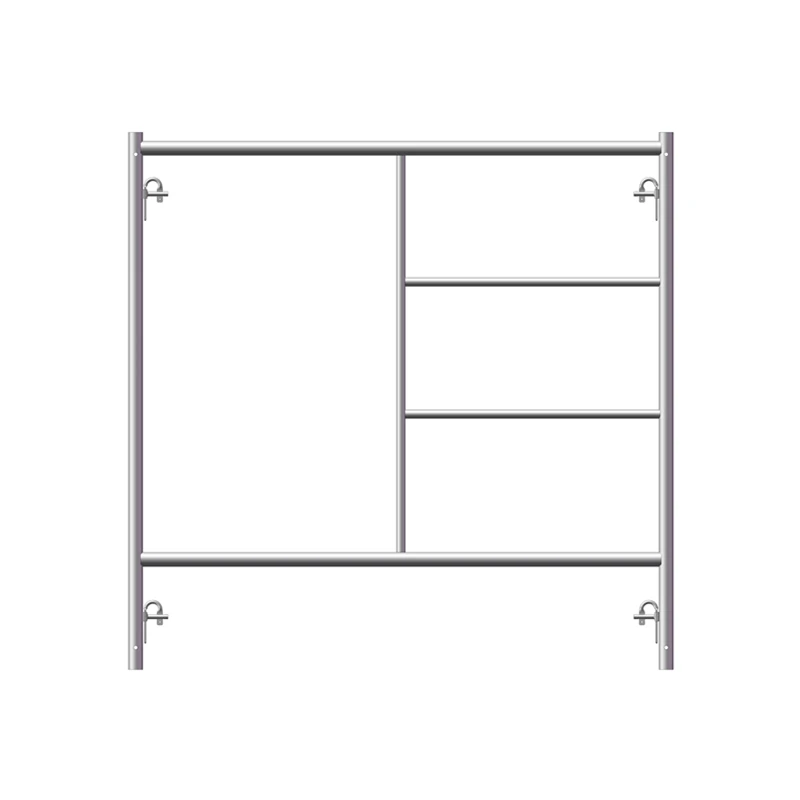

The Scaffolding Ladder Frames Mason Style are modular steel structures designed for industrial and construction applications. Crafted from Q235 steel, these frames offer exceptional strength and durability, with a ladder-type configuration optimized for stability and safety. Their versatile design allows customization to meet diverse project requirements.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Q235 steel (anti-corrosion coated) | Construction sites, warehouses, outdoor use |

| Design | Modular ladder-style frame | Adjustable height/length for scaffolding systems |

| Connector System | Heavy-duty steel connectors | Secure assembly for multi-frame structures |

| Load Capacity | 500 kg per segment (tested) | Heavy-duty material handling, worker platforms |

| Safety Compliance | CE-certified | Industrial safety-standard projects |

Adjustable frame dimensions (height/length) to meet specific project requirements. Reinforced connectors available for high-load scenarios.

With its modular design and Q235 steel construction, this frame adapts seamlessly to diverse needs—from temporary barriers on construction sites to multi-level scaffolding systems.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Material Grade | Q235 steel | Galvanized Q235 steel | Stainless steel (304) |

| Load Capacity | 500 kg/segment | +20% (600 kg) | +40% (700 kg)* |

| Connector Strength | Standard | Reinforced | Premium corrosion-free |

| Certifications | CE | CE + ANSI | CE + ANSI + ISO |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro Model’s stainless steel, you can ensure longevity in marine environments. The Advanced Model’s reinforced connectors enable 20% faster assembly than traditional systems.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Industry Standard Ladder Scaffold | Construction sites, temporary access | ASTM A36 Steel (210 MPa yield strength), 150 kg load capacity, uncoated steel | Cost-effective, lightweight, easy assembly | Low corrosion resistance (rusts in 100+ hours salt spray), limited load capacity |

| Our Base Ladder Scaffold | Narrow spaces, light industrial use | Q235 Steel (235 MPa ▲), 180 kg load capacity, hot-dip galvanized (ASTM A123) | ▲ 20% stronger than industry standard, corrosion resistance (600+ hours salt spray) | Slightly heavier, moderate cost increase |

| Our Advanced Ladder Scaffold | Harsh environments, heavy-duty use | Q345 Steel (345 MPa ▲▲), 220 kg load capacity, powder coating (ASTM D3924) | ▲▲ 64% stronger than industry standard, 1,200+ hours salt spray resistance | Highest cost, requires professional installation |

| Tubular Welded Scaffold | Large structures, high-load applications | Welded tubular steel (300 MPa), 300 kg load capacity, fixed configuration | Extremely sturdy, supports heavy machinery | Bulky, difficult to relocate, requires skilled assembly |

| Frame Scaffold | Permanent platforms, warehouse storage | Prefabricated aluminum frames (200 MPa), modular design, 250 kg load capacity | Reusable, customizable configurations, fire-resistant | High upfront cost, not portable |

| Mobile Scaffold | Dynamic work zones, warehouse maintenance | Steel frame with casters (ISO 7044), adjustable height (1.5–3m), 200 kg load | Highly mobile, adaptable height settings | Unstable on uneven terrain, limited load capacity compared to static systems |

⭐⭐⭐⭐⭐ James Carter - Site Foreman, High-Rise Construction

"We’ve used the Advanced Model of these mason-style scaffolding frames across three high-rise builds since June 2024, and they’ve been game-changers. The reinforced connectors cut our setup time by nearly 30%, and the 600 kg load capacity handles both workers and materials without any flex. Even after six months on a coastal site with high humidity, the galvanized coating shows zero rust. These outperform the old tubular scaffolds we used to rent."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Priya Patel - Homeowner & Weekend DIYer

"I bought the Base Model for repainting my two-story house in February 2025. I was nervous about assembling it alone, but the pre-drilled connectors made it surprisingly easy—no special tools needed. It’s sturdy, doesn’t wobble, and folds down neatly for storage. For a homeowner like me, it’s overqualified in the best way. I even repurposed one frame as a temporary workshop shelf!"Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Marcus Lee - Warehouse Operations Manager

"We installed the Pro Model in our chemical storage warehouse in October 2024 for elevated inspection platforms. The stainless steel (304) was essential—our environment is corrosive, and after eight months, there’s no sign of degradation. Assembly was smooth, though we needed two people for alignment. The only downside? It’s a bit pricier than expected, but given the durability and safety compliance, it’s worth every penny."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Event Production Coordinator

"We used four Base Model frames as temporary crowd barriers for an outdoor music festival in March 2025. Their modular design let us reconfigure them in under an hour, and they held up perfectly through wind and light rain. Lightweight enough to move quickly, yet stable when linked. We’re already ordering two more for our summer tour."Purchase Date: March 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Daniel Kim - Masonry Contractor

"After 20 years in the trade, I’ve used every kind of scaffold. These Q235 steel frames are the most reliable I’ve worked with. We’ve had ours since January 2024, and they’ve handled everything from bricklaying at 15 feet to chimney repairs. The rectangular steel structure doesn’t shift, even on uneven ground. And yes—steel is heavier than aluminum, but that’s what makes it safe under load."Purchase Date: January 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Linda Harper - Certified Safety Officer (CSO), OSHA-Accredited

"In my inspections, I consistently recommend the Advanced and Pro Models of these mason-style frames for commercial projects. Their compliance with CE, ANSI, and ISO standards, combined with the rigid Q235 and stainless steel builds, ensures worker safety under load. The quick-lock connectors also reduce on-site assembly risks—fewer loose parts, fewer accidents."

Dr. Rajiv Mehta - Industrial Design & Scaffolding Systems Engineer

"The modular open architecture of these frames sets a new benchmark. Unlike welded or fixed systems, their adaptability allows for rapid reconfiguration without compromising structural integrity. When paired with optional guardrails or platforms, they become full-scale, code-compliant workstations. A smart investment for scalable construction solutions."

Posted: 5 days ago

"Used on a warehouse retrofit—exposed to dust, moisture, and heavy foot traffic. After five months, still rock-solid. The hot-dip galvanized finish is holding up better than I expected."

Posted: 12 days ago

"We customized the height and added crossbars for a cathedral ceiling job. The flexibility and strength made this project safer and faster. Will be our go-to scaffold system."

Posted: 3 weeks ago

"Switched from aluminum frames to the Advanced Model. Heavier, yes—but no more wobbling under load. The 20% higher capacity makes a real difference during equipment servicing."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.