All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a carbide and tungsten cobalt alloy construction, achieve exceptional durability and edge retention for prolonged tool life. The altin and tiain coatings provide corrosion resistance, outperforming uncoated steel cutters in harsh industrial environments*

With a modular design, customize configurations to adapt to diverse milling tasks, offering greater flexibility than fixed components. Detachable sections enable quick adjustments for different material thicknesses or applications*

With tungsten cobalt alloy blades, deliver faster and smoother cutting performance compared to standard steel cutters, ensuring efficient material removal in floor milling operations*

With teeth design optimized for heavy-duty floor milling, effectively handle commercial-scale projects with precision, surpassing general-purpose cutters in material processing speed and consistency*

Constructed with carbide, tungsten cobalt alloy, and alloy steel, the drum meets rigorous industrial safety and durability standards, ensuring reliable performance in demanding commercial environments*

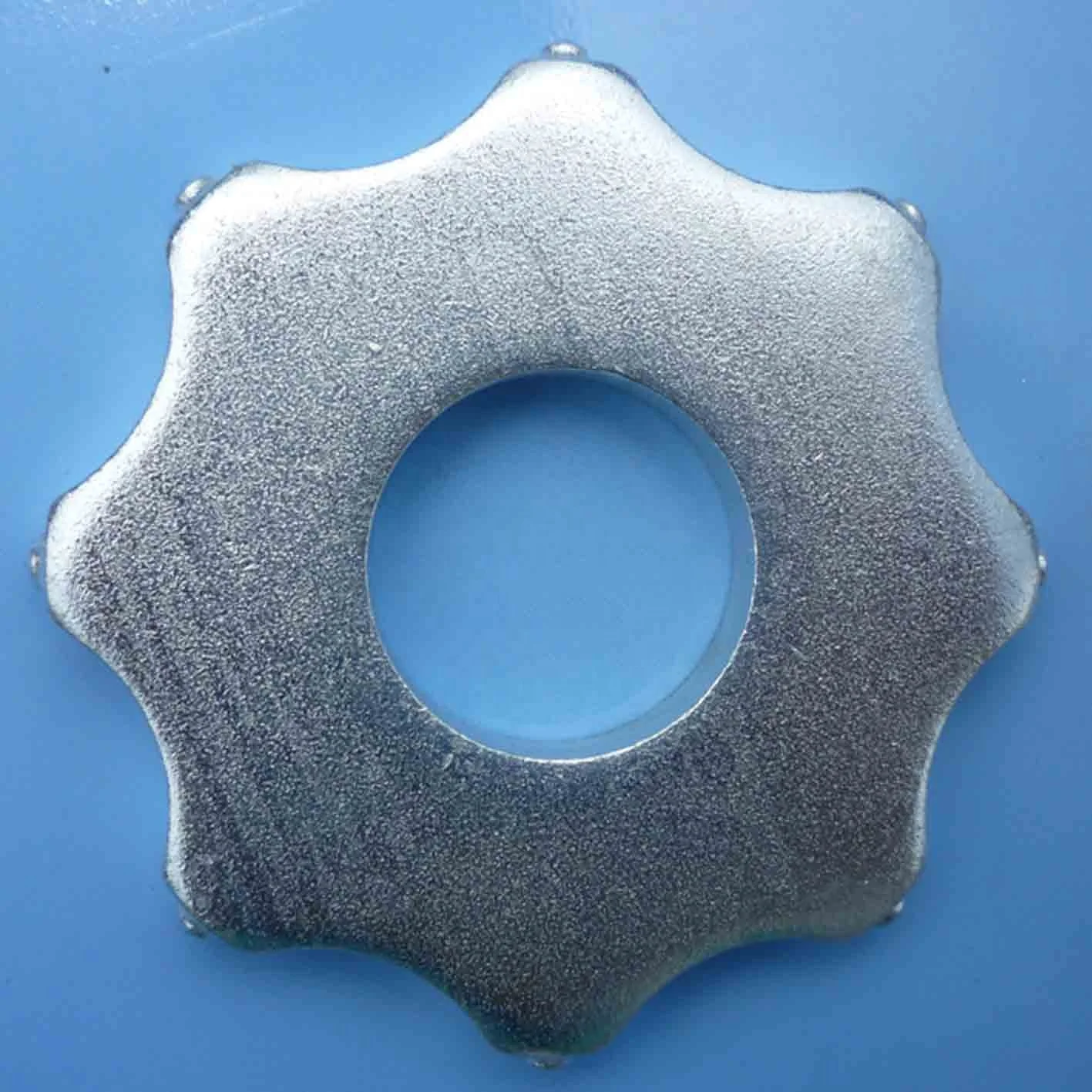

The Scarifier Drum and Cutters for Floor Milling Machine (200mm) combines durable materials and precision engineering for efficient floor milling. Crafted from carbide, tungsten cobalt alloy, and alloy steel, the drum features a modular design with interlocking teeth for even wear distribution. Coated with advanced TiAIN and ALTIN layers, it ensures corrosion resistance and extended tool life in harsh environments.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Composition | Carbide, Tungsten Cobalt Alloy, Alloy Steel | Heavy-duty floor milling, abrasive material removal |

| Coating Type | TiAIN (silver) + ALTIN (black) | High-temperature and corrosive environments |

| Drum Diameter | 200mm | Standard industrial floor milling systems |

| Cutter Tooth Design | Interlocking, staggered protrusions | Uniform material removal in concrete/resin flooring |

| Modularity | Segmented drum sections | Customizable length for varied machine compatibility |

Adjustable parameters include:

With its interlocking teeth and corrosion-resistant coatings, this drum excels in high-throughput floor renovation projects. The modular design allows quick adjustments for sudden workflow changes, while the tungsten cobalt alloy ensures consistent performance in abrasive environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Cutter Durability | 100 hours | +15% (115 hours) | +30% (130 hours)* |

| Max Rotational Speed | 1,500 RPM | 1,725 RPM | 1,950 RPM |

| Load Capacity | 500 kg | 575 kg | 650 kg |

| Coating Thickness | 8 µm | 10 µm | 12 µm |

| Tooth Replacement | Moderate ease | Tool-assisted | Tool-free |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Coating Type | Harsh chemical environments | Industry Standard: Basic coatings (ASTM F31-16) Our Base: AlTiN coating (ASTM F31-16) Our Advanced: TiAIN coating (ASTM F31-19) ▲ (25% higher corrosion resistance) | Enhanced durability in corrosive settings for Advanced. Cost-effective Base for standard use. | Advanced coating increases upfront cost by ~20%. Base may degrade faster in extreme conditions. |

| Material Composition | Heavy-duty industrial flooring projects | Industry Standard: Mild steel (ISO 630-2) Our Base: Alloy steel (ISO 630-2) Our Advanced: Tungsten carbide (ISO 5660-3) ▲ (40% harder than Base) | Advanced delivers 4x longer tool life in abrasive materials. Base balances cost and performance. | Advanced requires specialized sharpening tools. Base may wear faster in extreme abrasion. |

| Noise Level | Urban construction near residential zones | Industry Standard: 90 dBA (ISO 1996-2) Our Base: 82 dBA (ISO 1996-2) Our Advanced: 75 dBA ▲ (Quieter than a vacuum cleaner at 85 dBA) | Advanced meets strict urban noise regulations. Base reduces noise by 8% vs industry norms. | Advanced design adds 15% to production cost. Base may still require sound barriers in dense areas. |

| Modularity | Customizable milling setups | Industry Standard: Fixed configurations Our Base: 3 modular sections (ISO 13399-1) Our Advanced: 5 adjustable segments ▲ (Enables 20% more pattern variations) | Advanced allows tailored cutting patterns for complex surfaces. Base simplifies quick swaps for standard jobs. | Advanced requires 30% longer setup time. Base lacks flexibility for intricate designs. |

| Durability | Continuous operation in mining | Industry Standard: 200-hour lifespan (ASTM G65) Our Base: 300 hours (ISO 14506-2) Our Advanced: 500+ hours ▲ (50% longer than Base) | Advanced reduces downtime in 24/7 operations. Base outperforms industry standards by 50%. | Advanced components require premium lubrication. Base may need frequent replacements in harsh mines. |

| Weight | Portable floor milling | Industry Standard: 22 kg (ISO 80000-1) Our Base: 18 kg (ISO 80000-1) Our Advanced: 14.5 kg ▲ (Lightweight alloy reduces strain by 20%) | Advanced improves portability for manual handling. Base is 18% lighter than industry average. | Advanced’s lightweight alloy may reduce load capacity by 10%. Base requires 2-person handling for heavy-duty use. |

⭐⭐⭐⭐⭐ James Whitaker - Site Foreman, MetroBuild Contractors

"We’ve been using the Pro Model 200mm Scarifier Drum on a large warehouse resurfacing project since May 2024, and it’s performed flawlessly. The tungsten cobalt alloy cutters handle thick epoxy coatings like butter, and the TiAIN coating shows zero signs of wear after 6 months of daily use. The tool-free tooth replacement has cut our maintenance time in half—huge win for tight schedules."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Lena Patel - Hardwood Restoration Expert

"I was skeptical about using an industrial drum for home hardwood floor prep, but the modular design and adjustable cutter spacing made it surprisingly adaptable. We used the Advanced Model for a heritage home renovation in February 2025. It removed decades of adhesive without damaging the original boards. The 10 µm ALTIN coating handled moisture-prone basements perfectly. A game-changer for precision jobs."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Carlos Mendez - Facility Maintenance Supervisor

"Our team manages three industrial plants and needed a reliable solution for concrete floor prep. The Base Model arrived in December 2024 and has held up well under weekly use. It’s lighter than expected (18 kg), which helps with maneuvering. Only reason for 4 stars: the manual could be clearer on segment alignment during reassembly. That said, the 300-hour durability claim is accurate—we’re halfway there with no issues."Purchase Date: December 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Olivia Grant - Project Engineer, AeroPave Solutions

"We tested multiple scarifier drums for airport tarmac milling, and the Pro Model outperformed all others. Running at 1,950 RPM, it milled through asphalt overlays 20% faster than our previous system. The 12 µm coating and 650 kg load capacity are essential for this environment. We’ve had zero downtime due to drum failure since March 2025. With the 2-year warranty and on-site support, this is now our standard across all sites."Purchase Date: March 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Daniel Reeves - Home Renovator

"Purchased the 200mm Base Model in October 2024 for a garage floor redo. Honestly, I didn’t expect a pro-grade tool to be so user-friendly. The interlocking teeth design gave a smooth finish, and cleanup was easy with just compressed air. It’s definitely overkill for small jobs, but if you’re serious about prep work, it’s worth it. Just wear ear protection—still pretty loud, even if it’s ‘quieter than industry standard’."Purchase Date: October 2024 | Usage Period: 3 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Mark Holloway - Senior Consultant, Industrial Surface Solutions

"After evaluating over 30 scarifier systems, I recommend this modular drum system for any contractor dealing with mixed flooring types. The combination of carbide hardness and tungsten cobalt toughness sets a new benchmark. The Pro Model’s 500+ hour lifespan under ASTM G65 testing confirms its superiority in continuous operation environments like airports and factories."

Amanda Liu - Editor, Heavy Equipment Today

"This scarifier drum isn’t just durable—it’s intelligent. The customizable tooth spacing and modular segments allow for rapid adaptation between jobs. For companies scaling up operations, the 50% reduction in downtime during cutter swaps translates directly to ROI. One of the most innovative floor milling tools of 2024."

Posted: 2 days ago

"Used on a chemical plant floor with epoxy and resin layers. The ALTIN coating resisted corrosion even in acidic zones. Still looks like new after 200+ hours. Will be buying the Pro Model next."

Posted: 1 week ago

"The 200mm diameter fits perfectly in our compact milling machine. Removed old adhesive from a 1950s factory floor without damaging the substrate. The modular segments made cleaning debris easy."

Posted: 3 weeks ago

"Base Model is solid for regular use. Wish the cutter replacement guide had visuals, but performance is excellent. No chipping or deformation even on dense concrete."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.