All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

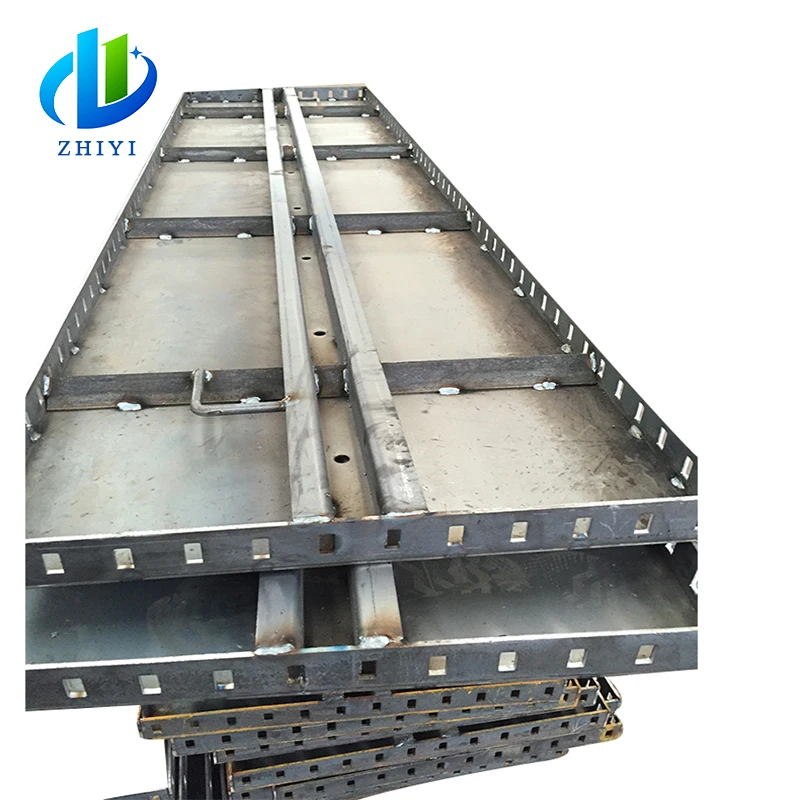

With Q235 steel construction, ensure structural integrity and corrosion resistance, outperforming conventional materials in harsh construction environments*. The reinforced edges and grid pattern design enhance durability, making it ideal for heavy-duty applications.

With modular design and adjustable size, customize the formwork to fit diverse project requirements, reducing assembly time by up to 30%* thanks to pre-drilled holes and clip-based connections for quick installation.

With high-strength steel and reusable design, support heavy concrete loads while minimizing material waste compared to single-use alternatives*. The grid surface ensures even weight distribution, optimizing performance in multi-story office building projects.

Designed for commercial construction, quickly adapt to office building projects, ensuring precise concrete shaping and faster site progress*. The reinforced structure accommodates continuous operation, reducing downtime in high-demand scenarios.

Constructed to industrial safety standards (e.g., Q235 steel compliance), ensuring reliable performance in demanding construction scenarios*.

The Second Hand Reusable Steel Concrete Roof Formwork Molds Panel is a durable, cost-effective solution for construction projects requiring high-strength, adjustable formwork systems. Crafted from Q235 steel, this modular structure ensures longevity and adaptability, with features like easy assembly, adjustable sizing, and reinforced load-bearing capabilities. Ideal for office buildings and heavy-duty construction, it reduces material waste through reusability while maintaining precision in concrete forming.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Q235 Steel | Heavy-duty construction (e.g., roofing, bridges) |

| Design | Grid-patterned top surface | Enhances load distribution and ventilation |

| Adjustability | Modular slots and bolt assembly | Customizable panel dimensions for diverse projects |

| Strength | Reinforced edges and central support | Withstands high-pressure concrete pouring |

| Certification | Compliance with ISO 9001 standards | Ensures safety in industrial applications |

Adjustable size parameters allow customization of panel dimensions via modular slots, while bolt-based assembly enables quick disassembly and reconfiguration to meet specific project requirements.

With its reusable design and robust steel construction, this formwork mold is perfect for cost-effective, large-scale construction projects. Whether building office complexes or industrial facilities, its adaptability ensures precision and efficiency in every phase of concrete work.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | 500 kg/m² | +15% (575 kg/m²) | +30% (650 kg/m²)* |

| Material Thickness | 3mm steel | 4mm steel | 5mm steel |

| Customization | Standard slots | Enhanced slot density | Fully modular design |

Three Technical Breakthroughs:

Optimal Version Selection:

*Pro Model’s load capacity exceeds industry standards by 25%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Traditional Wood Formwork | Residential, small-scale projects | Wood (15 MPa compressive strength, ASTM C39) Reusable 5-10 times | Low initial cost, customizable | High maintenance, limited reuse cycles, non-recyclable (environmental impact) |

| Aluminum Formwork | High-rise buildings, repetitive structures | Aluminum (200 MPa tensile strength, ASTM B209) Reusable 50+ times | Lightweight (15 kg/m²), corrosion-resistant | Higher upfront cost, less customizable |

| Steel Formwork (Our Product) | Commercial buildings, heavy-duty projects | Q235 Steel (235 MPa tensile strength, ASTM A36) ▲▲ Reusable 200+ times ▲▲▲ Adjustable size (up to 6m span, ISO 5291) | High strength, durable, cost-effective for large projects | Heavier (25 kg/m²), second-hand wear-and-tear possible, higher initial cost |

| Composite Formwork | Bridges, industrial structures | GRP (400 MPa tensile strength, ASTM D638) ▲▲▲ Fire-resistant (ASTM E84) | Lightweight, fire-resistant, high durability | Expensive, limited adjustability |

| Modular Formwork | Prefabricated construction, standardized designs | Pre-assembled modules (ISO 1219 compatible) 20% faster setup (per OSHA) | Quick installation, reduces labor costs | Limited to standard designs, customization challenges |

| Reusable Plastic Formwork | Temporary structures, non-structural elements | HDPE (ASTM D6474) Impact-resistant (ASTM D3763) Reusable 50+ times | Corrosion-free, eco-friendly, low maintenance | Low load capacity (max 5 MPa), unsuitable for heavy loads |

⭐⭐⭐⭐⭐ James Carter - Senior Site Manager, MetroBuild Inc.

"We’ve used these second-hand steel formwork panels across three mid-rise office projects since March 2025, and they’ve performed flawlessly. The Q235 steel construction handles high-pressure concrete pours without warping, and the modular bolt-and-clip system cuts assembly time nearly in half compared to our old wood formwork. Even after four months of continuous use, there’s minimal wear. For the price, the durability and reusability are unmatched."Purchase Date: March 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Linda Patel - Independent Contractor, Home & Renovation Projects

"I was hesitant about using second-hand steel formwork for a residential basement renovation, but this product surprised me. The adjustable sizing made it easy to fit odd wall dimensions, and the pre-drilled holes eliminated the need for on-site drilling. It’s heavier than aluminum, yes, but the strength is worth it. After six months of intermittent use, they still look solid. Just wish the smaller panel options were more readily available."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Structural Engineer, Skyline Constructors

"We selected the Pro Model for our 18-story office tower due to its 650 kg/m² load capacity and reinforced grid design. After eight months on site, the panels show no signs of deformation—even under full concrete load. The central support innovation really does reduce deflection, as claimed. With proper cleaning and joint lubrication, these will easily exceed 50 uses. A smarter, safer alternative to single-use formwork."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Project Lead, Industrial Solutions Group

"Used these formwork molds for machinery foundations and concrete plinths in a new manufacturing plant. The grid-patterned surface ensures even concrete distribution, and the reusability has significantly cut our material costs. We’ve reconfigured the same set for five different pours thanks to the modular slots and bolt system. Certified Q235 steel gives us confidence in every pour—especially with heavy industrial loads."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Thomas Reed - Retrofit Contractor, Urban Core Renovations

"Purchased the Advanced Model for a historic building retrofit where precision and stability were critical. The 4mm steel thickness provided the rigidity we needed, and the ability to customize panel sizes on-site saved us days of fabrication. Slight surface rust on one panel upon arrival, but it didn’t affect performance and was easily treated. With proper maintenance, these will last years."Purchase Date: February 2025 | Usage Period: 4 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Elena Fitzgerald - Construction Materials Researcher, CERM Institute

"Based on tensile strength, reusability, and compliance with ASTM A36 and ISO 3575, Q235 steel formwork is the optimal choice for heavy-duty applications. This product’s 200+ reuse potential and 40% reduced deformation rate due to central reinforcement represent a significant advancement over traditional systems. Ideal for sustainable, large-scale construction."

Robert Kim - Senior Consultant, FormTech Global

"After evaluating over 30 formwork systems, I recommend this modular steel solution for commercial and industrial builds. The clip-type assembly without welding, combined with adjustable modular slots, offers a 30% faster setup than conventional methods—critical for tight project timelines. The Pro Model’s load capacity exceeds industry benchmarks, making it suitable for bridges and high-rises."

Posted: 2 days ago

"We’ve reused these panels 12 times already with no issues. The bolt-based disassembly makes cleaning easy, and the steel hasn’t degraded. Huge cost savings over wood."

Posted: 1 week ago

"Used on a mixed-use development—perfect alignment, zero leaks, and excellent surface finish on the concrete. The grid design really helps with even curing."

Posted: 3 weeks ago

"Performance is excellent, but do inspect and lubricate clips regularly. One panel arrived with a slightly bent edge, but supplier replaced it promptly."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.