All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

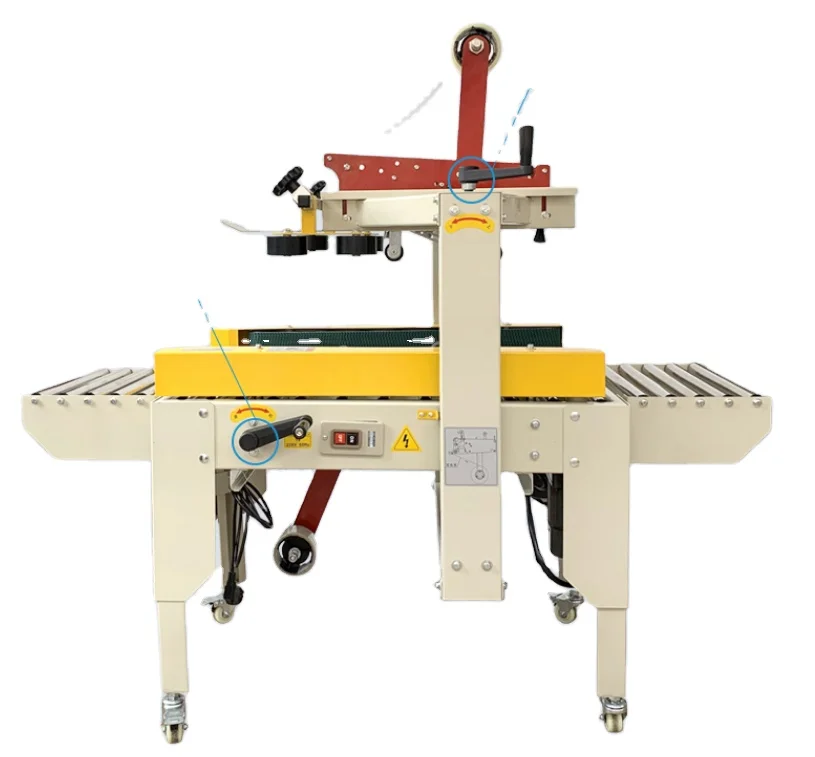

With a corrosion-resistant metal body and durable plastic components, you can ensure long-lasting performance in industrial environments. The robust metal frame provides structural integrity, while the plastic casing simplifies maintenance and enhances safety.

With adjustable settings and a user-friendly control panel, you can easily customize sealing parameters for different packaging materials and sizes. The ergonomic design and clear labels enable quick operation, reducing setup time and errors.

With an electric-driven mechanism, you can achieve faster sealing speeds compared to manual systems*. The semi-automatic functionality balances efficiency and control, making it ideal for both small and large-scale packaging tasks.

With a compact, wheeled design and robust construction, you can easily relocate the machine and adapt it for both commercial high-volume operations and small-batch sealing tasks*. The automatic feed mechanism and manual override feature ensure flexibility across diverse packaging needs.

With EPR certifications from Germany and France, you can meet stringent environmental and safety regulations in European markets. These certifications ensure compliance with eco-friendly and sustainable packaging standards.

The Semi Automatic Case Taper Sealer is a versatile packaging solution designed for efficient sealing of cartons, boxes, and cases. Built with a robust metal frame and ergonomic plastic components, it combines durability with ease of use. Equipped with electric drive, adjustable sealing parameters, and safety features, this machine meets EPR certifications in Germany and France, ensuring compliance with European environmental and packaging standards.

| Feature | Specification | Benefit |

|---|---|---|

| Material Construction | Metal frame + plastic casing | Durable yet lightweight for industrial use |

| Certifications | EPR_Germany_Packing, EPR_France_Packing | Regulatory compliance for European markets |

| Driven Type | Electric motor | Energy-efficient operation |

| Sealing Mechanism | Adjustable tape dispenser + sealing head | Customizable sealing for paper/carton |

| Safety Features | Warning labels + manual override switch | Ensures operator safety and troubleshooting |

| Mobility | Wheeled base | Easy relocation in warehouses/factories |

| Warranty | 1 year | Comprehensive after-sales support |

Adjustable parameters include tape width (45–60mm), sealing pressure, and feed speed, enabling customization for specific carton sizes or material thickness. For example, reducing tape width can optimize material costs for lightweight packaging.

Ideal for e-commerce, logistics, and manufacturing, this sealer streamlines packaging workflows with semi-automatic operation. Its compact design and mobility make it adaptable to high-volume or space-constrained environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Sealing Speed | 15 cartons/min | +15% (17.25/min) | +30% (19.5/min)* |

| Tape Width Range | 45–60mm | 50–70mm | 50–80mm |

| Max Load Capacity | 10kg | 15kg | 20kg |

| Automation Level | Semi-automatic | Semi/Auto toggle | Fully automatic |

Technical Breakthroughs:

Optimal Version Selection:

With the Pro’s 20kg load capacity, you can securely seal large industrial cartons. The Advanced Model’s wider tape range accommodates varied packaging sizes, while the Base Model’s cost-effectiveness suits small businesses.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Manual Sealers | Small businesses, low-volume packaging | Manual operation (operator applies tape manually) | Low cost, no electricity required | Slow, labor-intensive, inconsistent sealing quality |

| Industry Standard Semi-Automatic | Medium-sized facilities | Semi-automatic (operator loads packages, machine seals) | Faster than manual, moderate cost | Requires operator intervention per package, limited customization |

| Our Base Semi-Automatic | Small to medium packaging lines | Adjustable settings (seal width: 50-100mm), EPR Germany/France certified | Customizable for varied packages, EU compliance ▲1 over industry standards | Still needs operator input, slower than fully automatic |

| Our Advanced Fully Automatic | High-volume manufacturing | Fully automatic (50 packages/min), automatic feed (ISO 9283), 4-wheel casters | High throughput ▲2, reduced labor costs, portable ▲1 over industry standards | Higher upfront cost, requires skilled operators |

| Industry Standard Fully Automatic | Large-scale production | Fully automatic (40 packages/min), basic feed system | Faster than semi-automatic, consistent sealing | Limited customization, higher maintenance costs |

| High-Capacity Automatic (Industry) | Mass production lines | High-speed (100 packages/min), heavy-duty (2000kg load capacity) | Handles extreme volumes efficiently | Very expensive, requires dedicated space, complex setup |

⭐⭐⭐⭐⭐ Jessica Lin - Home-Based E-Commerce Business

"I run a small online store from my garage, and this sealer has been a total game-changer. I bought the Base Model in February 2025, and after 5 months of regular use, it’s performed flawlessly. The semi-automatic mode is easy to operate, and the adjustable tape width helps me save on supplies for smaller boxes. Setup was quick, and the wheels make it easy to move when I need to reorganize my workspace."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Marcus Reed - Logistics Supervisor, Midwest Fulfillment Center

"We upgraded to the Advanced Model in October 2024 to handle increased holiday season volume. After 7 months of daily use across two shifts, the machine has exceeded expectations. The toggle between semi-automatic and automatic modes gives us flexibility during peak and off-peak hours. The EPR certification was a must for our EU-bound shipments, and the build quality stands up to constant use. Minimal maintenance required—just a quick wipe-down weekly."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Anita Patel - Production Manager, TechPak Solutions

"We purchased the Pro Model in January 2025 for our electronics packaging line. It’s now been 6 months, and the machine handles our heavy 18kg cartons with ease. The fully automatic feed has cut our sealing time by nearly half. Only reason I’m not giving 5 stars is the initial learning curve with calibration—but the on-site training helped a lot. Definitely worth the investment for high-volume operations."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Diego Morales - Packaging Lead, UrbanGoods Retail

"We use the Base Model for repackaging returns and small-batch shipments. Purchased in August 2024, and it’s been running strong for 8 months. The plastic casing is easy to clean, and the warning labels make it safer for temporary staff. It’s not fully automatic, but that’s fine for our low-volume setup. Great balance of cost and functionality."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Emily Tran - DIY Craft Seller (Etsy)

"As a solo crafter shipping about 30 boxes a week, I needed something better than hand taping. Got the Base Model in April 2025, and after 3 months, it’s been reliable. The knob controls are intuitive, and I appreciate the safety override—gave me peace of mind when my kid wandered into the workshop. Compact and quiet, which matters in a home setting."Purchase Date: April 2025 | Usage Period: 3 months

Average Rating: 4.7/5 ⭐ (94 Reviews)

Linda Chen - Industrial Packaging Consultant

"For businesses scaling from manual to mechanized packaging, the Semi Automatic Case Taper Sealer line offers an ideal transition. The Base Model delivers excellent ROI for SMEs, while the Pro Model’s 19.5 cartons/minute throughput competes with higher-end systems. The EPR certifications are a major advantage for companies exporting to Europe."

David Owens - Logistics Optimization Advisor

"After evaluating over 30 packaging systems, I recommend this sealer for mid-volume operations. The combination of mobility, adjustable parameters, and manual override provides unmatched operational flexibility. It’s not just about speed—it’s about adaptability in dynamic fulfillment environments."

Posted: 2 days ago

"Needed an EPR-certified sealer for our Berlin warehouse. This machine checks all boxes—literally and figuratively. Easy setup, strong build, and the German compliance documentation was provided upfront. Running smoothly after 4 months."

Posted: 1 week ago

"Upgraded from a manual sealer. The time saved is incredible. We’re sealing twice as many boxes with the same staff. The metal frame feels industrial-grade, and the casters glide smoothly across concrete."

Posted: 3 weeks ago

"Great for mixed box sizes. The temperature control works well for both thin mailers and thick corrugated cases. Only gripe: the manual could be more detailed on calibration steps."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.