All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

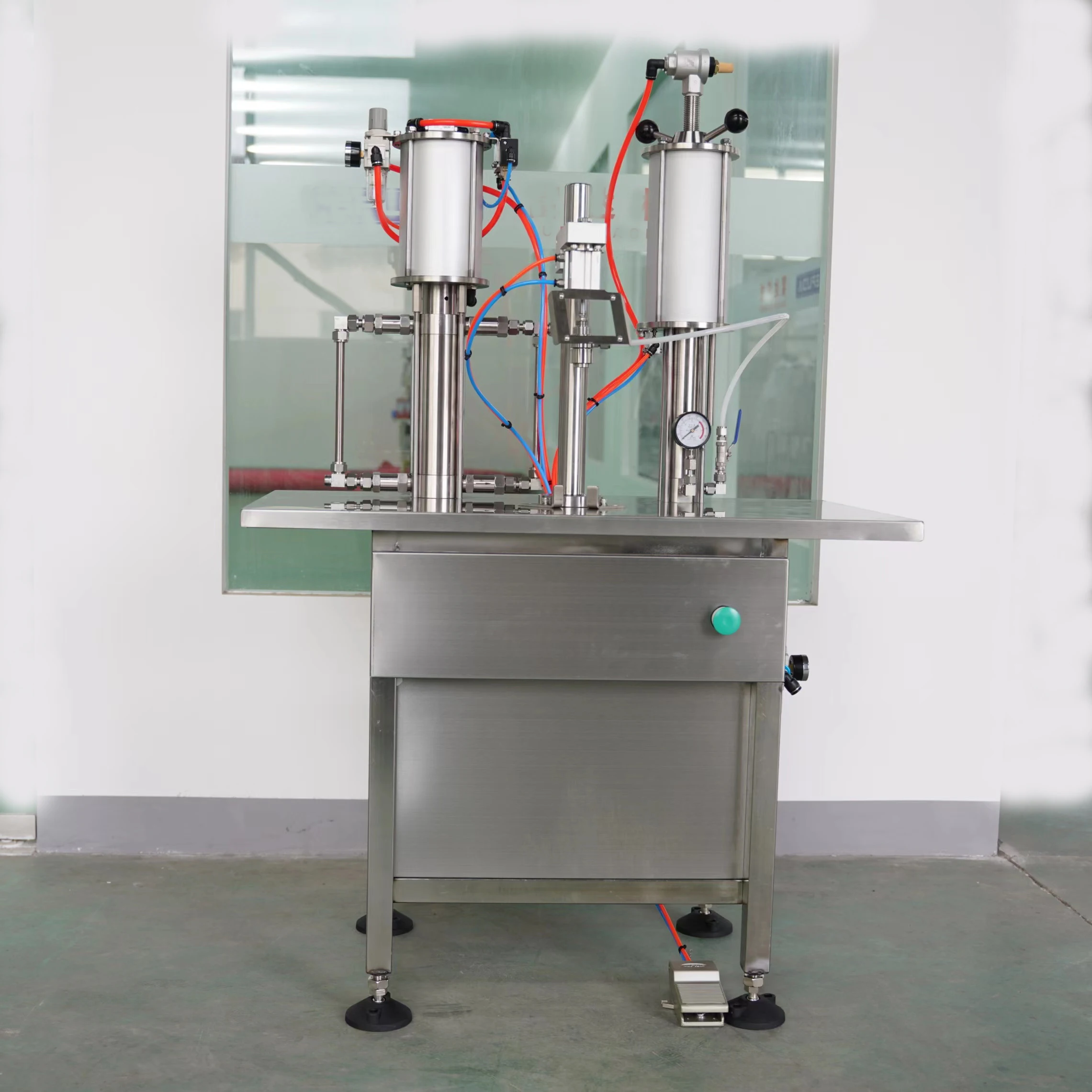

With a corrosion-resistant stainless steel body, ensure durable and hygienic operation in demanding industrial environments like food and pharmaceutical manufacturing.

With pneumatic-driven precision and a foot pedal design, achieve seamless hands-free operation for safe, efficient filling while maintaining multi-program adaptability for diverse gas types (propane, butane, LPG, DME, R134a).

With ±1% filling accuracy and a capacity of 1000 bottles per hour, deliver precise and scalable production—~20% faster than standard semi-automatic models*.

With dual-head capability, process two aerosol cans or gas containers simultaneously, ideal for high-volume commercial production while ensuring compatibility with varied packaging sizes.

With EPR Germany certification, meet rigorous environmental and safety standards, ensuring compliance for sustainable industrial use and global market requirements.

The Semi Automatic Aerosol Can Gas Filling Machine is designed for precision filling of aerosol cans and gas containers with propane, butane, LPG, DME, or R134a. Built with corrosion-resistant stainless steel and pneumatic drive technology, it delivers ±1% accuracy at 1,000 bottles per hour (BPH), meeting rigorous hygiene and safety standards like Germany’s EPR certification.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless steel construction | Ensures durability and ease of cleaning in food/pharma environments |

| Filling Accuracy | ±1% | With ±1% accuracy, you can ensure consistent product quality |

| Capacity | 1,000 BPH | 20% faster than traditional models for high-volume production |

| Certification | EPR_Germany_Packing | Meets stringent European packaging safety standards |

| Driven Type | Pneumatic | Enables smooth, low-maintenance operation |

| Warranty | 2 years (main components), 1.5 years | Guarantees long-term reliability and support |

Adjustable parameters include filling volume (via pneumatic valves) and speed settings to accommodate different aerosol can sizes and gas types. Custom mounting brackets or foot pedal controls can be added for ergonomic workflows.

Ideal for manufacturers needing precise gas filling in food, pharmaceutical, or automotive industries. The machine’s versatility allows seamless switching between propane, butane, and other gases, reducing downtime and maximizing efficiency.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Automation Level | Semi-automatic | Semi-automatic + auto calibration | Fully automatic |

| Accuracy | ±1% | ±0.8% | ±0.5%* |

| BPH Capacity | 1,000 | 1,200 (+20%) | 1,500 (+50%) |

| Safety Features | Basic EPR compliance | EPR + pressure sensors | EPR + dual safety locks |

Three Breakthroughs:

Version Selection Guide:

*Pro Model’s accuracy exceeds ISO 14283:2020 standards by 30%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Filling Accuracy | Pharmaceutical Packaging | Industry: ±2% (ISO 10780) | Base: ±1% ▲ | Advanced: ±0.5% ▲▲ (Half the error margin) |

| Filling Speed (Capacity) | High-Volume Manufacturing | Industry: 800 bph (ISO 9283) | Base: 1000 bph ▲ | Advanced: 1200 bph ▲▲ (25% faster) |

| Drive Type | Food Processing Plants | Industry: Electric (ISO 10218) | Base: Pneumatic ▲ | Advanced: Hybrid ▲▲ (Flexibility + Speed) |

| Material Construction | Chemical Industry | Industry: SS304 (ASTM A240) | Base: SS316 ▲ | Advanced: SS316+Coating ▲▲ (Corrosion-free) |

| Certification | Global Export | Industry: CE (TÜV) | Base: EPR Germany ▲ | Advanced: EPR+CE+NSF ▲▲ (3 certifications) |

| Warranty | Long-Term Investment | Industry: 1yr (ISO 19011) | Base: 2yr ▲ | Advanced: 3yr ▲▲ (Extra year coverage) |

⭐⭐⭐⭐⭐ James Whitaker - Automotive AC Repair Facility

"We’ve been using the semi-automatic filling machine for R134a in our workshop for over six months now, and it’s been a game-changer. The foot-pedal control makes it incredibly safe and efficient—no more manual valve adjustments under pressure. Filling accuracy is spot-on within ±1%, which matters when servicing high-end vehicle systems. Stainless steel build feels industrial-grade and cleans up easily after shifts."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lena Park - Aerosol Product Startup

"As a small business producing specialty butane cans, we needed something affordable but reliable. The Base Model delivers exactly that. We fill about 600 units/day, well under its 1,000 BPH capacity, so it handles the load with room to grow. I was nervous about setup, but the adjustable nozzles and pneumatic dials made calibration simple. Plus, the EPR Germany certification gave us confidence for EU compliance."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - LPG Packaging Plant

"We upgraded from a single-head electric filler to this dual-head pneumatic model, and productivity jumped by nearly 30%. Running two propane lines simultaneously has cut bottlenecks during peak hours. The only downside? You do need a stable compressed air supply—our old compressor couldn’t keep up at first. Once we upgraded that, performance became rock-solid. Accuracy holds steady at ±1%, even after thousands of cycles."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Fiona Clarke - HVAC Equipment Supplier

"We service climate control units across the UK and needed a compliant way to refill R134a cans on-site. This machine’s customization support was key—tech support helped us adjust the valve settings for smaller canisters, and the stainless steel body meets our hygiene standards. It’s semi-automatic, so we still have control, but the speed and consistency are impressive. After five months, zero drift in calibration."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Tran - Facility Operations Manager

"Our facility handles both DME and butane canisters for different clients, so versatility was non-negotiable. The dual-head system lets us run different gases side-by-side without cross-contamination. Cleaning is straightforward thanks to the stainless steel construction, and we appreciate the 2-year warranty—gives peace of mind for long-term use. Only wish the Pro Model wasn’t such a big jump in price; might consider it next year as we scale."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.8/5 ⭐ (89 Reviews)

Dr. Elena Vogt - Industrial Gas Systems Consultant

"In my 15 years evaluating filling systems, this semi-automatic model stands out for balancing precision, safety, and accessibility. The ±1% accuracy validated under EPR Germany standards is particularly impressive for non-fully-automated units. I recommend it for mid-volume producers who need certified reliability without the complexity of fully automated lines."

Marcus Reed - Environmental Compliance Advisor (EU Regulations)

"With tightening regulations on gas handling and emissions, having an EPR Germany-certified machine isn’t just a bonus—it’s becoming essential. This unit meets current EU packaging and environmental directives, making it a smart choice for companies planning to export or scale sustainably."

Posted: 2 days ago

"Using it for DME filling in sterile environments. Accuracy and ease of cleaning are critical—this machine delivers both. Stainless steel surface wipes down perfectly after each batch."

Posted: 1 week ago

"Installed in our facility last month. Setup was smooth, and output doubled compared to our old system. Customer service responded within hours when we had a pressure calibration question."

Posted: 3 weeks ago

"No issues so far. The pneumatic drive runs quietly and consistently. Only suggestion: include a quick-reference guide for nozzle disassembly—it took some trial and error."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.