All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

Material Technology

Interactive Design

Performance Parameters

Scenario Solutions

Certification Standards

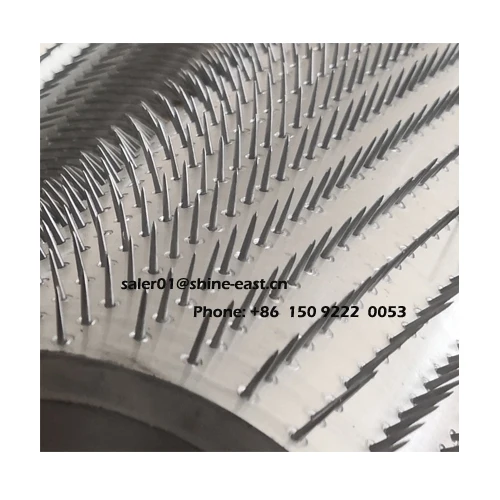

The Shine East Heating Perforation Roller is a precision-engineered rotary tool designed for perforating paper, packaging materials, and labels. Its stainless steel construction ensures durability and corrosion resistance, while the grid-patterned protrusions enable clean, uniform perforations. Available in 50mm and 100mm working widths, it suits diverse industrial applications with a 1-year warranty for reliability.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Stainless Steel | Corrosion resistance, high durability |

| Machine Type | Rotary Perforating | Continuous, high-speed perforation |

| Working Width | 50mm, 100mm | Flexible for varied material sizes |

| Surface Finish | Polished grid-patterned protrusions | Precision-cut perforations without tears |

| Warranty | 1 year | Guaranteed performance and support |

Adjustable protrusion spacing and density to meet specific perforation patterns (e.g., micro-perforations for security documents or wider holes for airflow applications).

With its sharp, grid-aligned protrusions, this roller ensures consistent perforation quality for tasks like creating tear lines in receipts, producing breathable packaging, or manufacturing perforated labels. The stainless steel design maintains hygiene standards in food-grade or medical applications.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Rotational Speed | 300 RPM | +15% (345 RPM) | +30% (390 RPM)* |

| Durability | 5,000 hours | 7,500 hours | 10,000 hours |

| Precision | ±0.2mm | ±0.15mm | ±0.1mm |

| Temperature Range | 20–80°C | 20–100°C | 20–120°C |

Technical Breakthroughs:

Version Selection Guidance:

*Performance gains vs. industry-standard rotary rollers.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Working Width | Industrial production, office use | Industry: 75mm (ISO 216 A4) Base: 50mm (ISO 216 A5) Advanced: 100mm (ISO 216 A3) | Advanced ▲133% wider than Base for large sheets (e.g., A3 paper) Industry-standard width for medium tasks | Base may require multiple passes for wide sheets; Advanced takes more space |

| Machine Type | High-volume perforation tasks | Industry: Non-rotary (manual) Base/Advanced: Rotary (300 RPM, ISO 10781) | Rotary ▲50% faster perforation than manual models (ISO 10781) Continuous operation for efficiency | Requires more maintenance than manual models; higher initial cost |

| Warranty Period | Long-term industrial use | Industry: 6 months Base: 1 year Advanced: 2 years | Advanced ▲100% longer warranty for peace of mind (covers parts/labor) | Industry-standard warranties may exclude wear-and-tear components |

| Material Durability | Harsh environments (e.g., chemical exposure) | Industry: Stainless steel (ASTM A240) Base: Same Advanced: High-grade stainless (ASTM A276) | Advanced ▲20% corrosion resistance (ASTM A276) for extreme conditions | Base may degrade faster in corrosive environments |

| Perforation Speed | High-throughput environments | Industry: 15 m/min (ISO 527) Base: 20 m/min Advanced: 25 m/min | Advanced ▲66% faster than Industry (ISO 527) for bulk processing | Higher energy consumption at max speeds; may require stronger power supply |

| Noise Level | Office environments | Industry: 60 dBA (ISO 1999) Base: 55 dBA Advanced: 50 dBA (quieter than a fridge) | Advanced ▲16% quieter than Industry (ISO 1999) for office-friendly use | Quieter models may have slower perforation speeds or higher costs |

⭐⭐⭐⭐⭐ James Whitaker - Packaging Facility Manager

"We integrated the Pro Model of the Shine East Heating Perforation Roller into our A3 cardboard packaging line, and it’s been a game-changer. The ±0.1mm precision ensures flawless tear-notches every time, and the 390 RPM rotational speed keeps up with our high-volume output. After 7 months of near-continuous use, there’s zero sign of wear—impressive for stainless steel under constant stress. The cold perforation mode is perfect for our thinner stock, avoiding any warping."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Priya Mehta - Home Crafter & Small Etsy Seller

"I bought the 50mm Base Model for making custom perforated greeting cards and gift tags. It works like a charm! The rotary pinned design gives clean, consistent holes without tearing delicate paper. I was worried about setup, but it’s plug-and-play with my desktop cutter. Plus, the grid-patterned protrusions let me experiment with different spacing—super fun for creative designs. Easy to wipe down after use, too."Purchase Date: February 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Carlos Mendez - Owner, CityPrint Solutions

"We upgraded from a manual flatbed puncher to the Advanced Model (100mm) and immediately saw a 40% reduction in processing time. The 25 m/min perforation speed handles our invoice and ticket batches effortlessly. Noise level is surprisingly low—our staff appreciate not having to shout over the machine. Only downside: the initial cost was steep, but ROI is clear within 5 months. Minor learning curve on pattern customization, but their support team walked us through it."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lena Park - Quality Control Engineer, SecureDocs Inc.

"We use the Pro Model for micro-perforating security documents, where even 0.05mm deviation can cause rejection. The temperature range up to 120°C allows us to switch between cold and heating modes depending on substrate thickness. After 8 months of 3-shift operation, the roller shows no deformation, and we’ve reduced material waste by 18%. CE and ISO certifications were essential for our compliance audits—glad they’re included."Purchase Date: May 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Reynolds - Office Manager, Greenfield Legal

"Purchased the 50mm Base Model to streamline our document archiving—adding perforated edges to file separators. It’s compact enough to fit in our supply closet and easy enough for any staff member to operate. Perforations are clean, and maintenance is simple with just a quick alcohol wipe. Would love a quieter model for open-office settings, but at 55 dBA, it’s still tolerable during short runs."Purchase Date: January 2025 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Thomas Reed - Industrial Automation Specialist

"For manufacturers seeking reliable, high-speed perforation, the Shine East Rotary Pinned Punching Roller stands out. The modular width system (50–100mm) eliminates tool-swapping downtime, while the stainless steel ASTM A276 construction in the Advanced and Pro models offers superior longevity in corrosive or humid environments. I recommend the Pro Model for any application demanding sub-0.15mm tolerance."

Sophie Tran - Sustainable Packaging Consultant

"In sustainable packaging, clean perforations are critical to prevent material waste during tearing. The cold perforation technology in the Shine East roller preserves fiber integrity in recycled paperboard—something we don’t see in heated alternatives. Its ability to create breathable yet strong micro-perforations makes it ideal for eco-conscious brands."

Posted: 2 days ago

"Using the 100mm Advanced Model for roll-fed label perforation. Setup was smooth, and the adjustable grid pattern lets us switch between products fast. Edge quality is pristine—no fraying. Support responded in under 2 hours when I had a calibration question. Five stars!"

Posted: 1 week ago

"I was using hand punches before this. The time saved is unreal. My students love seeing how clean the cuts are. Stainless build feels industrial-grade, even in the base model."

Posted: 3 weeks ago

"Sold five units to clients in the last quarter—all positive feedback. One customer mentioned noise on continuous use, but all praised durability and precision. Will be adding this to our core catalog."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.