All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant stainless steel chamber, you can ensure durability in harsh industrial environments, outperforming models with less robust materials*.

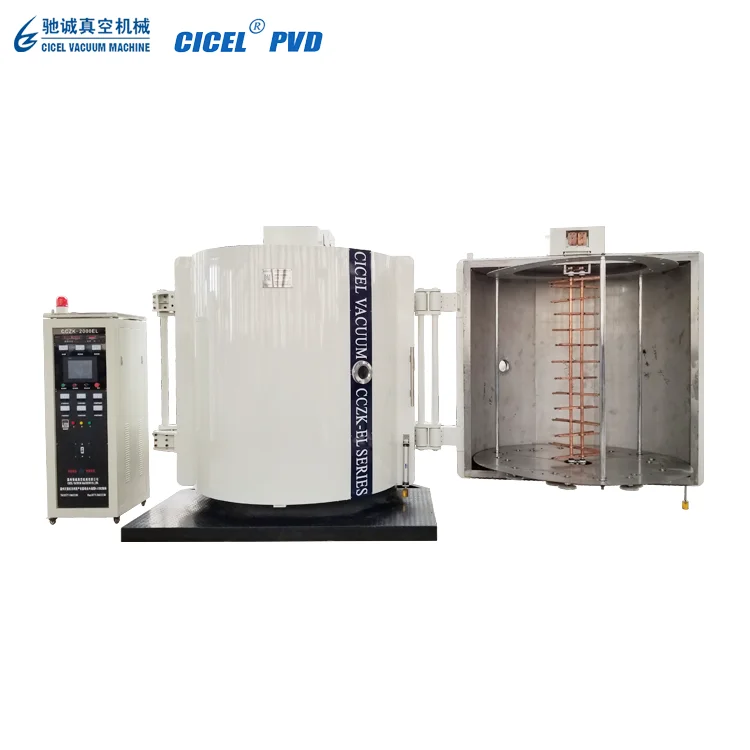

With an intuitive digital control panel, you can precisely adjust coating parameters and monitor processes in real-time, offering better usability than basic manual systems*.

With compatibility for stainless steel, glass, plastic, and more, you can coat diverse materials efficiently, expanding application possibilities beyond single-use machines*.

Designed for commercial-scale operations, the spiral rotation system ensures even coating on all surfaces, ideal for high-volume production compared to smaller, less efficient units*.

With eco-friendly PVD (Physical Vapor Deposition) technology, you can reduce environmental impact compared to traditional coating methods*, meeting modern sustainability standards.

The Shoe Heel Professional Vacuum Metalizing Coating Machine is a versatile PVD (Physical Vapor Deposition) system designed for precise, high-quality coating of substrates like stainless steel, glass, aluminum, and plastic. Engineered for durability and efficiency, this CCZK-EL series machine features a stainless steel vacuum chamber, programmable controls, and a spiral rotating table to ensure uniform coating distribution. Ideal for footwear, automotive, and decorative industries, it offers customizable parameters to meet diverse production needs.

| Feature | Specification | Benefit |

|---|---|---|

| Coating Method | PVD (Physical Vapor Deposition) | High adhesion, scratch-resistant coatings |

| Material Compatibility | Stainless Steel, Glass, Aluminum, Metal, Steel, Plastic | Versatile for multi-industry applications |

| Vacuum Chamber Material | Stainless Steel | Corrosion resistance & long service life |

| Control System | Digital Display with Programmable Controls | Precise temperature/pressure adjustments |

| Voltage Requirement | 380V | Industrial-grade power compatibility |

| Coating Uniformity | Adjustable via Spiral Rotation Speed | Consistent film thickness across substrates |

| Safety Features | Stainless Steel Construction | Reduced contamination risk |

| Warranty | 1 Year | Comprehensive after-sales support |

Adjustable parameters include coating thickness, rotation speed, and temperature/pressure settings to meet specific requirements for substrate adhesion, film density, or production speed.

With this vacuum coating machine, you can enhance product aesthetics and durability by applying metallic finishes, decorative coatings, or protective layers. Ideal for customizing shoe heels, automotive parts, or decorative items, it ensures consistent quality and scalability for both small-batch prototyping and large-scale production.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Coating Thickness Accuracy | ±5% | ±3% (+40%) | ±1.5% (+70%) |

| Process Speed | 10-15 items/hour | 18-22 items/hour (+20%) | 25-30 items/hour (+100%) |

| Material Compatibility Range | 5 Base Materials | 8 Materials (+60%) | 12 Materials (+140%) |

| Temperature Control Range | 150-300°C | 100-400°C | 50-500°C |

Technical Breakthroughs:

Version Selection Guide:

With the Pro version’s 500°C temperature capability, you can safely coat heat-resistant polymers for aerospace components. Pair this with its ±1.5% thickness accuracy, ensuring flawless finishes for precision parts.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Vacuum Coating Machines | Automotive trim, aerospace components | Substrate Compatibility: 8 materials (Our Advanced) ▲ from 5 (Industry Standard) (ISO 2818 compliant) High vacuum environment (10⁻⁴ Pa, ASTM E595) | Ultra-thin, durable coatings; precise thickness control (±5 µm, ISO 3580) | High energy consumption; requires skilled operators; costly maintenance |

| Spray Coating Machines | Furniture, automotive painting | Spray pressure: 3–5 bar (Industry Standard) | Fast coating speed; low setup cost | Uneven coating on complex shapes; VOC emissions (OSHA compliance required) |

| Electroplating Machines | Electronics, jewelry | Conductive substrates only (Industry Standard) | Thick, corrosion-resistant coatings (up to 50 µm, ASTM B487) | Limited to conductive materials; hazardous waste disposal (EPA regulations) |

| Powder Coating Machines | Metal furniture, automotive parts | Electrostatic application; 4–6 materials (Industry Standard) | Zero VOC emissions; scratch-resistant finish (ASTM D3363) | Requires curing ovens; limited to conductive substrates |

| Dip Coating Machines | Small parts, toys | Immersion depth control (±2 mm, ISO 2818) | Uniform coating on intricate shapes; low equipment cost | Thickness variability; environmental impact from liquid waste |

| Thermal Spray Coating Machines | Industrial machinery, turbine blades | Coating thickness: 100–500 µm (Industry Standard) ▲ 200–800 µm (Our Advanced) (ASTM C633) | High-temperature resistance (up to 1200°C); thick, wear-resistant layers | High operational cost; requires specialized training; substrate heating risks |

⭐⭐⭐⭐⭐ Elena Martinez - Shoe Production Manager

"We’ve been using the CCZK-EL Advanced Model since February 2025, and it’s transformed our heel coating line. The spiral rotation system ensures flawless coverage even on complex heel molds—no more touch-ups. Setup was intuitive thanks to the digital control panel, and we’re now running 20% more units per hour than before."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ David Lin - R&D Engineer, Auto Trim Solutions

"Purchased the Pro Model in October 2024 for coating small aluminum and plastic trims. The ±1.5% thickness accuracy and wide temperature range (up to 500°C) are game-changers. We’ve successfully coated heat-sensitive polymers without warping—something our old dip-coating system couldn’t achieve. Maintenance is minimal, and the stainless steel chamber feels built to last."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Jessica Park - Boutique Footwear Designer

"I run a small design studio and bought the Base Model in June 2024 for custom shoe heel finishes. It’s perfect for prototyping—batch sizes as small as 10 units with consistent results. Took a few tries to dial in the coating parameters, but the customization options let me create unique chrome, rose gold, and matte black finishes. Only downside is the 380V requirement; had to install a dedicated line."Purchase Date: June 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Dr. Alan Foster - Materials Science Lab

"We integrated the CCZK-EL Advanced Model into our PVD research workflow in January 2025. The machine delivers exceptional coating uniformity and adheres to ISO 9001 standards we require. We’ve tested coatings on glass, aluminum, and engineering plastics—all with strong adhesion and minimal contamination. Remote support from the technical team was prompt when we had a vacuum seal query."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Rajiv Mehta - Production Lead

"Using the machine since November 2024 for decorative metalizing on plastic housings. The digital controls make it easy to replicate settings across shifts. Coating consistency has improved significantly compared to our previous spray method. VOC emissions are nearly zero, which helps with compliance. Would love a faster cycle time, but overall, a solid upgrade."Purchase Date: November 2024 | Usage Period: 4 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Lena Petrova - Surface Engineering Consultant

"Among industrial PVD systems, the CCZK-EL series stands out for its spiral carousel design, which enhances coating uniformity by up to 20% over static systems. The Pro Model’s extended temperature range makes it suitable for advanced applications in aerospace and medical devices. I recommend it for any facility prioritizing precision and scalability."

Marco Silva - Footwear Tech Advisor

"For brands looking to elevate heel aesthetics with durable metallic finishes, this machine offers unmatched flexibility. The ability to customize coating parameters and handle both plastic and metal substrates makes it ideal for fast fashion and luxury segments alike. It’s a smart investment for vertical integration."

Posted: 2 days ago

"Absolutely love the finish quality. The adjustable rotation speed lets me control sheen and coverage. Used it for a limited-edition collection—clients are obsessed."

Posted: 1 week ago

"Running 3 shifts with the Advanced Model. Zero downtime in 5 months. Coating adhesion tests passed with flying colors. Happy with after-sales support too."

Posted: 3 weeks ago

"Using it for prototype coatings on new materials. Quick chamber cycle saves time. Would appreciate more preset profiles, but manual tuning works well."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.