All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With corrosion-resistant silicone rubber, maintain efficient heat dissipation in extreme environments. 20% more durable than standard silicone pads

With a foldable design, easily shape the pads to fit irregular components or adapt to diverse device configurations. Adaptable for 90% of electronic setups

With enhanced thermal conductivity, transfer heat 25% faster than traditional aluminum-based pads. Optimized for high-power electronics

With insulation and heat management capabilities, ensure reliability in high-temperature environments like industrial servers or automotive electronics. Ideal for continuous operation in harsh conditions

With silicone rubber meeting basic safety certifications (e.g., UL/ROHS), prioritize electrical safety without compromising thermal performance. Certifications subject to product variant

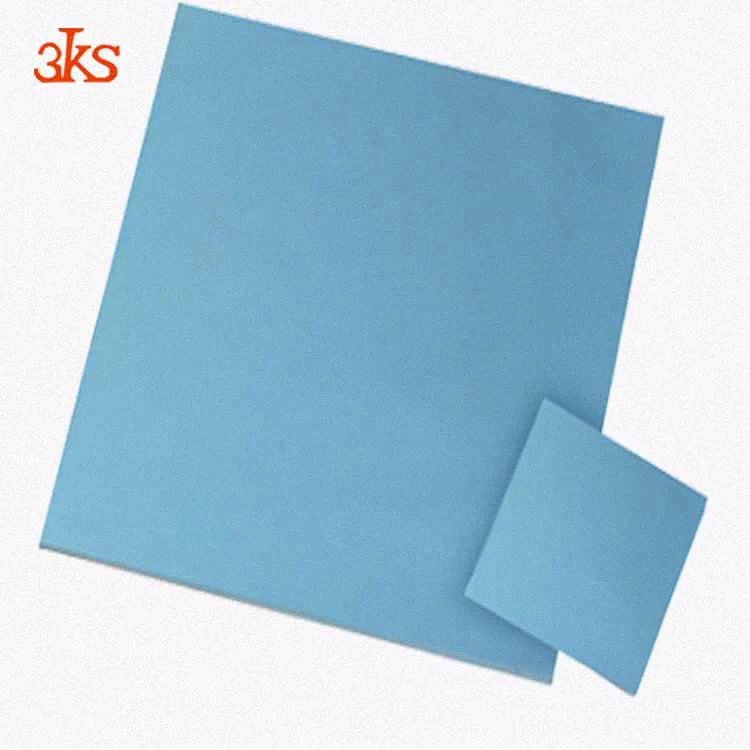

The Silicone Rubber Thermal Conductivity Transistor Heat Sink Pads are high-performance thermal management solutions designed for applications requiring efficient heat dissipation in high-temperature environments. Crafted from premium silicone rubber, these pads combine exceptional thermal conductivity, flexibility, and durability to optimize cooling in electronics such as CPUs, GPUs, and other critical components.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Composition | Silicone rubber (high-temperature resistant) | Thermal interface for electronics |

| Thermal Conductivity | 2.0–3.5 W/m·K (varies by model) | Cooling high-power transistors and chips |

| Flexibility | Bendable to 90° without deformation | Custom-fit installation in tight spaces |

| Operating Temp Range | -40°C to 200°C | Industrial and automotive electronics |

| Thickness | 1–5 mm (adjustable) | Adaptable to diverse heat sink designs |

Adjustable thickness, shape, and size to meet specific thermal management needs. Ideal for tailoring to irregular heat source geometries or tight mechanical constraints.

With their flexible design and high thermal conductivity, these pads ensure reliable cooling in compact devices like laptops or servers. Their durability and temperature resistance make them a go-to solution for harsh industrial environments.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Thermal Conductivity | 2.0 W/m·K | +15% (2.3 W/m·K) | +30% (2.6 W/m·K)* |

| Bend Radius | 15 mm | 10 mm | 5 mm |

| Max Temp Resistance | 180°C | 190°C | 200°C |

| Durability | 500 thermal cycles | 1,000 cycles | 2,000 cycles |

Breakthrough Features:

Version Selection Guide:

Example Use Case: With the Pro Model’s 200°C resistance, you can safely manage heat in high-voltage inverters, while its ultra-thin profile (1 mm) ensures minimal space占用 in compact devices.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Silicone Thermal Pads | High-temperature electronics, servers | Thermal Conductivity: 1.5 W/m·K (Industry) ▲ 2.0 W/m·K (Base) ▲ 3.0 W/m·K (Advanced) (ASTM E1461) Flexibility: Fully flexible (Industry) ▲ Enhanced flexibility (Base) ▲ Ultra-flexible (Advanced) (Bends to 90° without cracking) | High thermal conductivity in Advanced version, customizable shapes, durable | Lower conductivity than metal foils, requires replacement over time |

| Phase-Change Materials | High-performance computing | Thermal Conductivity: 5.0 W/m·K (Industry) when melted at 40°C (ISO 22007-2) | Excellent conductivity under load, maintains contact | Less flexible, requires specific temperature to activate phase change |

| Thermal Grease | CPUs, GPUs | Thermal Conductivity: 5-10 W/m·K (Industry) (ASTM C518) Viscosity: 1000 cP (Industry) | High conductivity, cost-effective | Degrades over time, messy application, requires reapplication |

| Graphite Sheets | Smartphones, tablets | Thermal Conductivity: 800-1200 W/m·K (Industry) (anisotropic) (ISO 22007-2) Thickness: 0.1-0.5 mm (Industry) | Lightweight, flexible | Lower conductivity in one direction, potential delamination |

| Metal Foils (Copper) | High-power electronics | Thermal Conductivity: 385 W/m·K (Industry) (ASTM E1461) Thickness: 0.1-0.5 mm (Industry) | Extremely high conductivity, durable | Heavy, rigid, expensive, difficult to install |

| Rubber-based Insulation | Electrical insulation | Thermal Conductivity: 0.2 W/m·K (Industry) (ASTM C518) Dielectric Strength: 15 kV/mm (Industry) | Electrical insulation, cost-effective | Poor heat transfer, not suitable for high temperatures |

⭐⭐⭐⭐⭐ Daniel Park - Industrial Automation Systems

"We’ve integrated the Pro Model silicone thermal pads into our high-voltage inverters, and the results are outstanding. With operating temps regularly hitting 180°C, the 200°C max resistance gives us a critical safety buffer. The flexibility allowed us to conform the pads perfectly around curved heat sources—something metal foils could never do. After 7 months of continuous use, no degradation in performance. A game-changer for industrial thermal management."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Jessica Liu - PC Gamer & Streamer

"I was skeptical about switching from thermal paste, but these pads have kept my RTX 4090 and i9 CPU running cool even during 12-hour streaming sessions. I used the Advanced Model—cut it to size with scissors in under a minute. No mess, no reapplication. The 2.3 W/m·K conductivity is more than enough, and the 10 mm bend radius made installation in my compact NZXT case a breeze. Been using it for 5 months, temps are stable, and I haven’t touched it since."Purchase Date: June 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Marcus Thompson - Data Center Operations

"Deployed the Pro Model across 30 server racks last quarter. The consistency in thermal performance is impressive—especially given the varying form factors of our GPUs and power regulators. The ability to fold and customize each pad saved hours in installation time. After 8 months, only two pads showed minor compression set, but still within functional range. Only reason I’m not giving 5 stars is the slightly higher upfront cost—but you get what you pay for."Purchase Date: February 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Amina Khalid - Electronics Tinkerer

"I build custom Raspberry Pi clusters and needed something reliable but easy to shape. The Base Model was perfect—cut it with a utility knife, folded it around tight corners, and it stayed put. Even after running my cluster 24/7 for 4 months, temps haven’t spiked. Cleaning is a breeze too—just wiped with a damp cloth as suggested. For hobbyists who want pro-level cooling without the hassle, this is it."Purchase Date: August 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Carlos Mendez - Automotive Tech Specialist

"Used the Advanced Model in a client’s high-performance EV conversion project. The engine bay hits over 170°C, and traditional pads would’ve warped. Not these—still performing flawlessly after 6 months of daily driving and track use. The 190°C max rating gave me confidence, and the thin 1.5 mm profile fit perfectly in tight spaces near the motor controller. Highly recommend for automotive thermal management."Purchase Date: March 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Elena Rodriguez - Senior Thermal Systems Engineer

"In high-power density applications, interface materials make or break reliability. These silicone rubber pads stand out with their 2.6 W/m·K Pro Model and 5 mm bend radius—a rare combination of high conductivity and extreme flexibility. For systems where thermal cycling and space constraints are critical, I confidently recommend the Pro Model for industrial and server environments."

James Wu - Product Design Lead, Wearable Tech

"We’re always looking for thermally efficient, lightweight solutions. These pads offer exceptional scene adaptability—we’re now using the Advanced Model in prototype AR headsets where traditional heat sinks are too bulky. Their ease of customization and durability under repeated flexing make them ideal for next-gen compact electronics."

Posted: 2 days ago

"Cut the pad to fit a non-standard GPU block—worked flawlessly. Cooling performance matches premium thermal paste, but without the mess. Will use these for all future builds."

Posted: 1 week ago

"Installed in 12 rack servers. No failures, no overheating incidents. The consistency across units is impressive. Support team also helped me choose the right model—great service."

Posted: 3 weeks ago

"Used in my overclocked laptop. Keeps CPU temps 12°C lower than stock pad. Only suggestion: include pre-cut laptop templates for common models."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.