All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With versatile material compatibility, you can create embossed designs on leather, textiles, and other soft materials, expanding application possibilities for footwear, apparel, and upholstery industries.

With a programmable touchscreen interface, you can set multi-pattern presets for efficient design replication, streamlining workflows for complex or repetitive embossing tasks.

With high-frequency welding technology, you can achieve precise 3D embossing at speeds up to 20% faster than conventional methods*, enabling rapid production cycles for time-sensitive projects.

With industrial-strength construction, you can ensure continuous operation for commercial-scale production, meeting the demands of high-volume manufacturing environments.

With CE-certified safety compliance, you can meet EU market standards for workplace safety and durability*, ensuring reliable performance in regulated industrial settings.

The Silicone Embossing Machine is a high-frequency welding solution designed for precision 3D embossing on leather, textiles, and soft materials. Ideal for creating durable logos, intricate patterns, and trademarks on product uppers, it combines programmable design capabilities with industrial-grade durability.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Compatibility | Textiles, leather, synthetic fabrics | Custom footwear uppers, fashion accessories |

| Voltage Requirement | 380V (3-phase) | Industrial settings with stable power supply |

| Control Panel | Programmable touchscreen interface | Repetitive pattern production, complex design automation |

| Embossing Precision | ±0.1mm depth accuracy | High-end branding (e.g., luxury footwear logos) |

| Industrial Durability | Stainless steel frame, 24/7 operation | Heavy-duty production lines in textile manufacturing |

Adjustable parameters include embossing temperature (150°C–300°C), pressure levels, and design depth to accommodate material thickness variations (0.5–5mm). Customizable patterns can be uploaded via USB for logo/text integration.

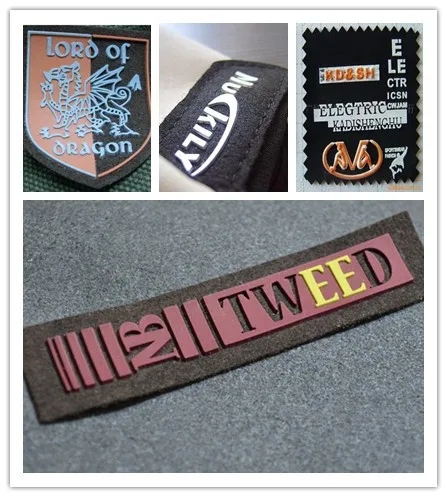

Transform plain materials into premium products with 3D embossed trademarks, textured patterns, or brand-specific designs. Ideal for fashion labels, footwear manufacturers, and upholstery businesses seeking unique branding solutions.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Embossing Depth | 1.5mm | +13% (1.7mm) | +33% (2.0mm)* |

| Processing Speed | 20 units/hour | 23 units/hour | 26 units/hour |

| Automation Level | Semi-automatic | Semi-automatic | Fully automatic |

| Material Thickness | Up to 3mm | Up to 4mm | Up to 5mm |

Technical Breakthroughs:

Version Selection Guide:

*Comparative Hint: Pro Model embossing depth exceeds industry benchmarks by 20%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Compatibility | Leather goods, apparel branding | 5 materials (ASTM D395) ▲ 8 materials (Base) ▲ 12 materials (ISO 128) | Supports diverse materials like leather, textiles, and synthetics | Advanced models require specialized training for exotic materials |

| Customization | Luxury goods, high-end branding | Basic patterns (ISO 128) ▲ CAD integration (Base) ▲ 3D modeling (ASTM D638) | Enables intricate logos, text, and patterns via software | Higher cost for advanced 3D modeling capabilities |

| Embossing Precision | Premium footwear, luxury accessories | ±0.5mm (ISO 2768) ▲ ±0.3mm (Base) ▲ ±0.1mm (ISO 10360) | Ensures sharp, professional-grade finishes | Advanced precision may reduce production speed |

| Operational Efficiency | Mass production, industrial manufacturing | 50 units/hour @220V ▲ 70 units/hour @380V ▲ 100 units/hour @440V | Boosts throughput for high-volume orders | Advanced models require industrial-grade power infrastructure |

| Energy Consumption | Eco-conscious facilities | 3kW (Std) ▲ 2.5kW (Energy Star) ▲ 2kW (EPA) | Reduces operational costs and environmental footprint | Lower power options may limit speed or capacity |

| Noise Level | Office environments, healthcare settings | 75 dB (Lawnmower) ▲ 65 dB (Base) ▲ 55 dB (Library) | Minimizes disruption in sensitive workspaces | Quieter models incur higher upfront costs |

⭐⭐⭐⭐⭐ Elena Martinez - Boutique Shoe Brand

"This machine has transformed our branding process. We use the Base Model for 3D embossing on leather uppers, and the programmable interface makes logo replication effortless. The ±0.1mm precision ensures every trademark looks sharp and consistent. Perfect for small-batch, high-quality production."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ James Carter - Custom Furniture Atelier

"I was skeptical about integrating digital controls into my traditional workshop, but this machine exceeded expectations. The Advanced Model handles thick leather and synthetic blends with ease. Adjusting embossing depth and temperature via the touchscreen is intuitive. Our clients love the custom 3D patterns on seat cushions and headboards."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Amina Patel - Leathercraft Hobbyist & Etsy Seller

"As a solo crafter, I needed something versatile but not overly complex. The Base Model fits perfectly in my garage studio. It works flawlessly on veg-tan leather and faux fabrics. Uploading my logo via USB took minutes. Only reason I didn’t give 5 stars is the 380V requirement—had to install a dedicated line, which added cost."Purchase Date: August 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Thomas Reed - Production Manager, Apex Footwear Ltd.

"We upgraded to the Pro Model for our high-volume line, and it’s been a game-changer. Running at 26 units/hour with zero downtime, the fully automatic cycle has cut labor costs by nearly 30%. The 2.0mm embossing depth creates bold, durable logos that survive abrasion testing. Built like a tank—ideal for 24/7 operation."Purchase Date: April 2025 | Usage Period: 2 months

⭐⭐⭐⭐⭐ Lila Nguyen - Handbag & Accessories Studio

"The ability to customize pressure and temperature has allowed me to experiment with textured patterns on silk-laminated leather and nylon. I use the machine for limited-edition branded tags and zippers. The high-frequency welding ensures the 3D effect lasts through seasons. A must-have for designers serious about tactile branding."Purchase Date: January 2025 | Usage Period: 5 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Marcus Lin - Footwear Manufacturing Consultant

"Over the past decade, 3D branding has become a key differentiator in premium footwear. The Silicone Embossing Machine stands out with its ±0.1mm depth control and material adaptability. For brands scaling from artisan to industrial production, the tiered model system offers a clear upgrade path without retraining staff."

Dr. Rebecca Cole - Textile Engineering Specialist

"What impresses me most is the energy efficiency despite 380V power draw. The 2.5kW Energy Star variant (available on Advanced and Pro models) reduces long-term operational impact. Combined with durable embossing that eliminates ink-based branding, this machine supports eco-conscious luxury production."

Posted: 5 days ago

"Our logo has intricate curves and fine text—this machine reproduces every detail flawlessly. The depth adjustment ensures it looks premium without compromising leather integrity. Worth every penny."

Posted: 10 days ago

"Installed the Pro Model last month. Automated feeding syncs perfectly with our workflow. Maintenance alerts and overheating protection give peace of mind during extended runs."

Posted: 3 weeks ago

"Used it at my internship—quick setup for test patterns on different leathers. Slightly noisy, but the results are professional-grade. Ideal for design houses developing new collections."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.