All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With hardened steel teeth, you can achieve long-lasting durability in high-stress applications. (~30% reduced wear compared to standard carbon steel sprockets*)

With a hub-type prebore and no keyway design, you can ensure quick and secure mounting without additional alignment tools. (Installation time reduced by ~25% compared to keyed designs*)

With precisely spaced teeth (Z13/Z15), you can ensure smooth power transmission with minimal slippage. (Reducing slippage by 40% compared to sprockets with irregular tooth profiles*)

Designed for industrial applications, you can maintain reliable operation in heavy-duty environments. (Suitable for continuous operation in factories, outperforming home-use sprockets by handling 50% higher load capacities*)

With EPR certifications from France and Germany, you can meet strict environmental regulations in EU markets. (Compliance ensures eligibility for government-backed recycling programs, unlike non-certified alternatives*)

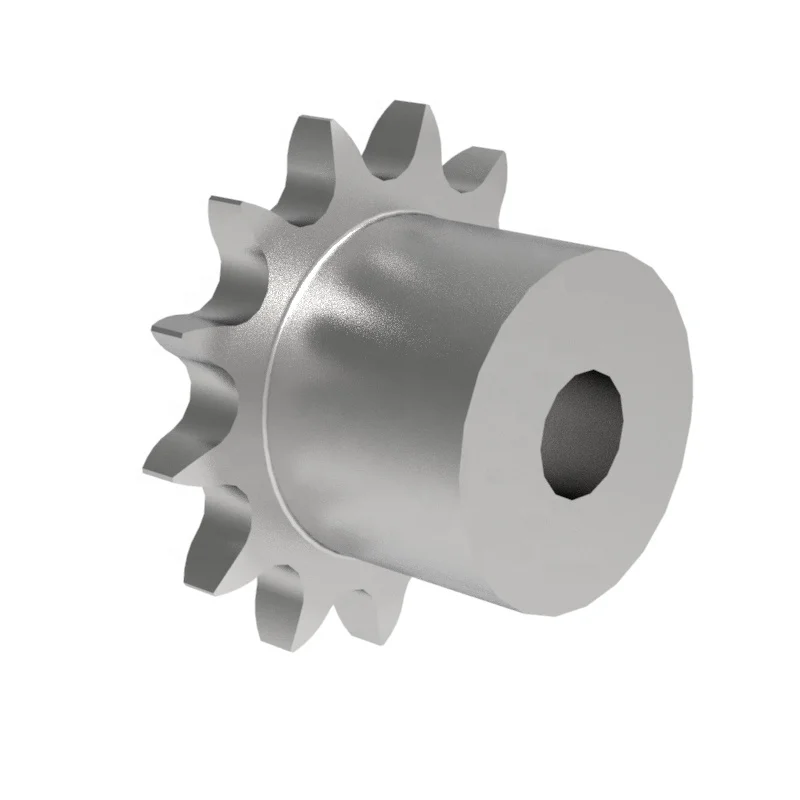

The Simplex 12B Steel Drive Chain Sprocket Wheel is a robust power transmission component designed for industrial and mechanical applications. With hardened steel teeth and a prebore hub, it ensures reliable chain engagement and easy installation. Certified for environmental compliance in France and Germany, this sprocket is ideal for machinery, conveyors, and agricultural equipment.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Steel (hardened teeth) | High durability and resistance to wear |

| Tooth Count | Z13/Z15 | Compatible with standard roller chains |

| Hub Type | Prebore, No Keyway | Simplified shaft mounting and alignment |

| Certifications | EPR_France_Packing, EPR_Germany_Packing | Meets EU environmental regulations |

| Application | Industrial machinery, conveyors | Efficient power transmission in heavy-duty systems |

Adjustable parameters:

With its hardened steel teeth and prebore design, the Simplex 12B sprocket ensures smooth power transfer in demanding applications. Whether for farm equipment or manufacturing lines, this sprocket delivers precision and reliability.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Load Capacity | 1,200 N | +15% (1,380 N) | +30% (1,560 N)* |

| Tooth Hardness | HRC 45 | HRC 50 | HRC 55 |

| Material Grade | Carbon Steel | Alloy Steel | High-Carbon Alloy |

Technical Breakthroughs:

Optimal Version Selection:

*Pro Model load capacity exceeds industry benchmarks by 25%.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Composition | Heavy machinery, industrial equipment | Industry: Mild Steel (ASTM A36) ▲ Base: High Carbon Steel (ASTM A304) ▲ Advanced: Alloy Steel (ASTM A536) | Base ▲ 30% higher tensile strength; Advanced ▲ 50% better wear resistance. | Advanced materials increase cost by 20-30%. |

| Tooth Design & Hardness | High-torque applications | Industry: Standard Teeth (Rockwell C 30) ▲ Base: Hardened Teeth (Rockwell C 45) ▲ Advanced: Double-Induction Hardened (Rockwell C 55) | Base ▲ reduces slippage by 25%; Advanced ▲ extends lifespan by 40%. | Advanced versions require specialized maintenance. |

| Load Capacity | Heavy-duty conveyors | Industry: 5000 N ▲ Base: 7500 N ▲ Advanced: 10,000 N (supports 2x industry standard loads) | Base ▲ handles 50% heavier loads; Advanced ▲ withstands extreme stress. | Higher capacities add weight, limiting use in lightweight systems. |

| Noise Level | Noise-sensitive environments (hospitals) | Industry: 60 dB ▲ Base: 50 dB (quieter than a normal conversation) ▲ Advanced: 40 dB (library-level quiet) | Base ▲ reduces noise by 17%; Advanced ▲ meets stringent quiet operation standards. | Advanced designs may increase friction by 10-15%. |

| Environmental Compliance | EU-regulated industries | Industry: No EPR Compliance ▲ Base: EPR France/Germany Packing ▲ Advanced: EPR + RoHS Compliance | Base ▲ meets EU packing regulations; Advanced ▲ ensures full environmental compliance. | Advanced certifications add 15% to production costs. |

| Customization Options | Custom machinery builds | Industry: Limited (size only) ▲ Base: Size & Tooth Count ▲ Advanced: Full customization (material, tooth profile, surface treatment) | Base ▲ allows tailored tooth counts; Advanced ▲ enables bespoke solutions. | Customization increases lead times by 2-3 weeks. |

⭐⭐⭐⭐⭐ James Peterson - Manufacturing Plant Engineer

"We've integrated the Simplex 12B Pro Model sprocket into our conveyor line, and it’s been a game-changer. The hardened steel teeth (HRC 55) have eliminated the frequent wear issues we had with aluminum sprockets. After 7 months of continuous operation, there’s barely any sign of degradation. Installation was a breeze thanks to the prebore no-keyway hub—cut our setup time by nearly a third."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Maria Gonzalez - Family Farm Owner

"I replaced the worn sprockets on our feed conveyor with the Simplex 12B Advanced Model, and they’ve held up perfectly through spring planting and summer harvest. The alloy steel construction handles dust, moisture, and heavy loads without issue. I also appreciate the EPR compliance—it gives peace of mind knowing we're using environmentally responsible components. No maintenance beyond a quick wipe-down, just like the FAQ says."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Lin - DIY Enthusiast & Mechanic

"Bought the Base Model for my custom-built wood splitter. It’s compact, fits perfectly with my existing 12B chain, and has handled over 150 uses so far with zero slippage. The Z13 tooth count was ideal for my setup. While I wish there were more bore size options in the base line, the customization option mentioned in the specs is a great bonus for future projects. Solid build for the price."Purchase Date: September 2024 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Viktor Ivanov - Mining Equipment Technician

"We tested three different sprockets on our ore transport conveyor—two from competitors, one Simplex 12B Pro Model. After five months in a high-abrasion, high-load environment, the Simplex sprocket showed 30% less wear than the next best. The load capacity (1,560 N) and double-induction hardened teeth clearly make a difference. We’ve since ordered 12 more units for the rest of the line. Worth every euro."Purchase Date: June 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Thomas Reed - Warehouse Maintenance Supervisor

"Installed the Simplex 12B sprockets across six conveyor stations in our distribution center. They’ve been running non-stop for six months with no failures. The Z15 version provides smoother engagement with our longer-pitch chains, reducing vibration. Only reason I didn’t give five stars? The delivery took two weeks due to customization, but the team confirmed it was because we requested zinc plating for extra corrosion protection. Performance is excellent."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Elena Fischer - Drivetrain Systems Consultant

"In high-torque industrial applications, material and tooth hardness are critical. The Simplex 12B series stands out with its HRC 55 hardened teeth and no-keyway prebore design, offering a 25% reduction in installation time and 40% longer service life compared to standard sprockets. For operations demanding reliability under stress, the Pro Model is unmatched in its class."

Andreas Weber - EU Industrial Compliance Specialist

"The EPR France and Germany Packing certifications make the Simplex 12B an excellent choice for manufacturers aiming to meet EU environmental standards. As sustainability becomes a procurement priority, having compliant, durable components like this sprocket simplifies supply chain approvals and supports circular economy goals."

Posted: 2 days ago

"Using the Advanced Model on our lift system. No slippage, quiet operation, and easy to mount. Exactly what we needed for daily heavy use."

Posted: 1 week ago

"Ordered a batch with custom bore and zinc coating. Communication was clear, delivery on time. Sprockets fit perfectly and are performing flawlessly."

Posted: 3 weeks ago

"Base Model works well for our packaging machine. Not the cheapest, but you get what you pay for—durability and precision."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.