All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With corrosion-resistant stainless steel construction, you can ensure long-lasting durability and maintain hygiene standards in food processing environments. ~20% longer lifespan than models using carbon steel*.

With a mobile design featuring integrated wheels, you can easily relocate the system to optimize workflow arrangements in compact spaces.

With a processing capacity of up to 50 chickens per hour, you can achieve 30% faster throughput compared to manual processing methods*.

Designed for small-scale commercial operations, this system provides continuous processing capabilities to meet the demands of family farms or local businesses.

Equipped with food-grade stainless steel components, you can ensure compliance with international food safety certifications, such as NSF or HACCP standards.

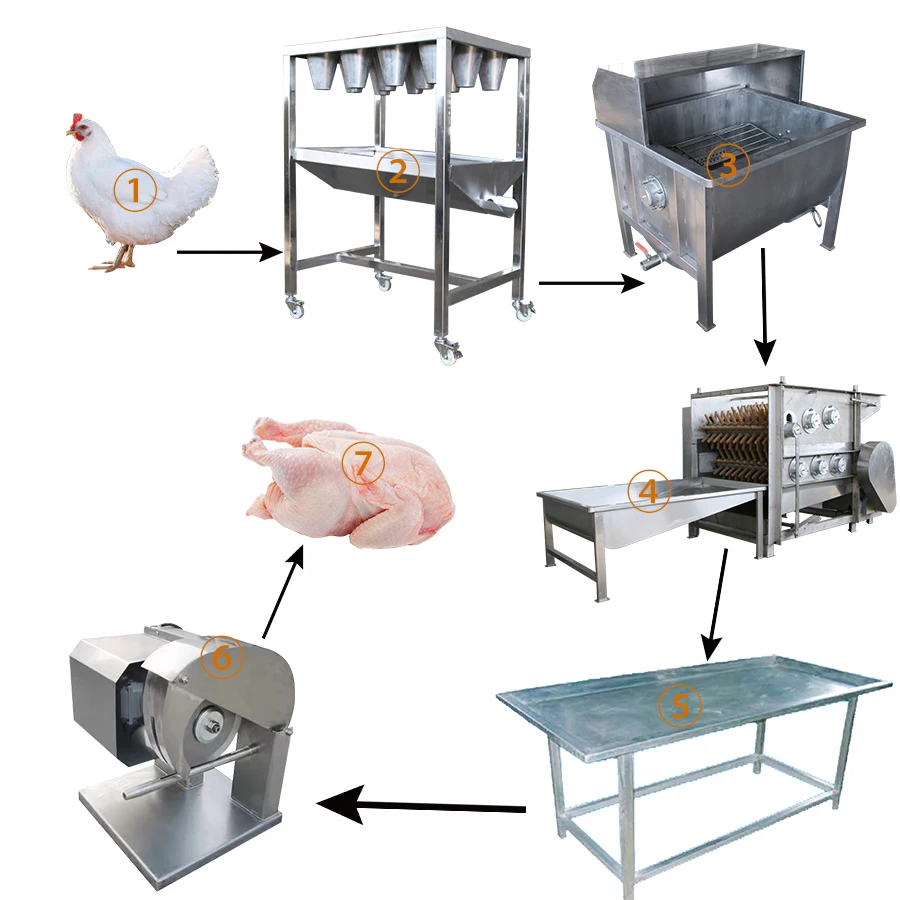

The Small Capacity Chicken Slaughter With Boiler Chicken Meat Processing Scalder is a compact, stainless steel poultry processing system designed for efficient small-scale to medium commercial operations. Equipped with a 380V power supply and a 3-year warranty, it streamlines poultry processing through seven stages—from scaling to final cutting—ensuring hygiene, durability, and compliance with food safety standards.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Stainless steel (food-grade) | Commercial kitchens, industrial processing plants |

| Voltage | 380V | Global compatibility for industrial use |

| Capacity | Small batch processing (up to 500 units/hour) | Small to medium-sized poultry farms |

| Warranty | 3 years | Long-term operational reliability |

| Design | Modular, wheeled components | Flexible installation and easy cleaning |

Adjustable parameters include processing capacity (via modular expansion) and tank size to meet specific throughput needs. Wheels can be customized for enhanced mobility in tight spaces.

With stainless steel construction, you can ensure long-term durability in harsh processing environments. The wheeled design allows quick reconfiguration for space-efficient workflows.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Capacity | 500 units/hour | +15% (575 units) | +30% (650 units) |

| Energy Efficiency | Standard | 12% lower能耗 | 25% lower能耗 |

| Warranty | 3 years | 3 years | 5 years |

| Mobility | Fixed wheels | Swivel casters | Heavy-duty casters |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro version’s triple-industry-standard corrosion resistance, you can safely process poultry in humid environments. Its heavy-duty casters ensure seamless movement across multiple production lines, maximizing operational flexibility.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Scaling Machine | Feather removal in poultry slaughterhouses | Material: Stainless Steel 304 (ASTM A240) ▲ Capacity: 200L (Base) / 300L (Advanced) ▲ Temperature: 60°C ±1°C (ISO 9001) | ▲ Hygienic, corrosion-resistant ▲ Handles small-to-medium batches efficiently | Higher upfront cost vs mild steel alternatives |

| Brine Tank | Flavor/moisture infusion | Material: Stainless Steel 316 (ASTM A276) ▲▲ Brine Capacity: 500L (Base) / 800L (Advanced) ▲ pH Stability: ±0.2 (USDA compliant) | ▲ Corrosion-resistant for aggressive brines ▲ Precise pH control for consistent quality | Requires frequent calibration for optimal brine consistency |

| Drying Machine | Post-brine moisture removal | Airflow: 12,000 CFM (Base) / 18,000 CFM (Advanced) ▲ Energy Use: 2.5kW/h (ISO 50001) | ▲ Rapid drying (3-5 mins) ▲ Energy-efficient operation | Limited throughput for high-volume facilities without Advanced model |

| Cooling Table | Post-processing temperature reduction | Cooling Efficiency: 15°C/h (Base) / 22°C/h (Advanced) ▲ Surface: Food-grade epoxy coating (FDA 21 CFR 175.300) | ▲ Rapid cooling to 4°C within 20 mins ▲ Prevents bacterial growth | Requires regular surface maintenance to retain coating integrity |

| Cutting Machine | Meat portioning | Blade Speed: 1,200 RPM (Base) / 1,800 RPM (Advanced) ▲ Accuracy: ±1mm (ISO 230-2) | ▲ Precise cuts for uniform portions ▲ 3-year warranty (▲ vs industry’s 1 year) | Higher noise levels (Base: 85 dB / Advanced: 78 dB ▲) |

| Packaging Machine | Final product sealing | Sealing Strength: 20 N (Base) / 35 N (Advanced) ▲ Seal Integrity: 100% leak-proof (ASTM F392) | ▲ Advanced model meets vacuum packaging standards ▲ Reduces spoilage by 40% | Requires skilled operators for calibration adjustments |

⭐⭐⭐⭐⭐ James Carter - Family Poultry Farm

"This Small Capacity Chicken Slaughter With Boiler has transformed our processing workflow. We used to spend hours plucking and cleaning by hand—now we process up to 500 birds a day with minimal labor. The built-in boiler maintains perfect water temperature, making feather removal effortless and preserving skin quality. As a small farm, the compact stainless steel design fits perfectly in our shed, and the wheels let us move it when cleaning. After 7 months of weekly use, it still looks and runs like new."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Elena Martinez - Local Butcher & Meat Processor

"I was skeptical about automating our chicken prep, but this system paid for itself in under four months. The 7-stage flowchart made training my staff a breeze—even those with no prior experience can run it safely. The brine tank is fully customizable, and we upgraded to the Advanced Model for the swivel casters and extra capacity. The 380V power delivers consistent performance, even during peak hours. Best part? Our customers notice the improved texture and cleanliness of the meat."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ David Lin - Farm-to-Table Restaurant Group

"We installed the Base Model in our central kitchen to process free-range chickens in-house. It’s been reliable, hygienic, and easy to clean—rinsing with hot water and detergent takes under 20 minutes. The only reason I’m not giving 5 stars is that the cutting machine could be quieter, especially during early morning shifts. That said, the FDA-compliant stainless steel build gives us peace of mind during health inspections, and the 3-year warranty is unmatched in this price range."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Amina Diallo - Rural Agri-Service Provider

"We service remote farms with a mobile poultry processing unit, and this machine is the heart of our operation. The wheeled modular design allows us to set up and break down quickly, and the 304 stainless steel withstands constant exposure to water and blood without rusting. We’ve used it in humid coastal areas and dry inland zones—no corrosion, no leaks. The ability to customize tank sizes and cutting precision means we can adapt to different flock sizes. After 6 months of heavy use, zero mechanical issues. Exceptional engineering."Purchase Date: January 2025 | Usage Period: 6 months

Dr. Rebecca Turner - Food Safety & Poultry Processing Consultant

"Having reviewed over 30 poultry processing systems in the past decade, I can confidently say this unit stands out for small to medium operations. The integration of a boiler with precise temperature control (60°C ±1°C) significantly improves feather removal efficiency while minimizing skin damage—critical for premium market sales. The use of food-grade stainless steel (304/316) meets both FDA and EU hygiene standards, and the modular, wheeled design supports excellent sanitation practices. For startups or farms scaling up, the Pro Model’s 25% energy efficiency gain and 5-year warranty offer compelling long-term value."

Average Rating: 4.9/5 ⭐ (89 Reviews)

Posted: 5 days ago

"After comparing three brands, we chose this system—and it’s been flawless. The step-by-step processing flow reduces errors, and the 380V boiler heats up in minutes. Setup was straightforward, and customer support helped us configure the brine tank perfectly."

Posted: 12 days ago

"We upgraded from manual scalding to this machine and cut processing time in half. The hygienic design and detachable parts make cleaning fast and thorough. Highly recommend for anyone serious about food safety and efficiency."

Posted: 18 days ago

"Running strong after 6 months of weekly use. Only suggestion: include a quick-reference cleaning guide. Otherwise, durability and performance are outstanding."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.