All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant steel body, you can ensure long-lasting durability in harsh industrial environments.*

With a CNC-controlled touchscreen interface, you can program precise punching parameters and adjust multi-task presets 25% faster than manual models.*

With 450kN nominal force and hydraulic power, you can achieve high-precision punching at speeds up to 20% faster than mechanical models.*

With a modular design, you can customize the machine for evaporator fin production lines, adapting to varied manufacturing needs 40% faster than fixed systems.*

With construction meeting rigorous industrial safety standards, you can ensure reliable operation under heavy loads and demanding conditions.*

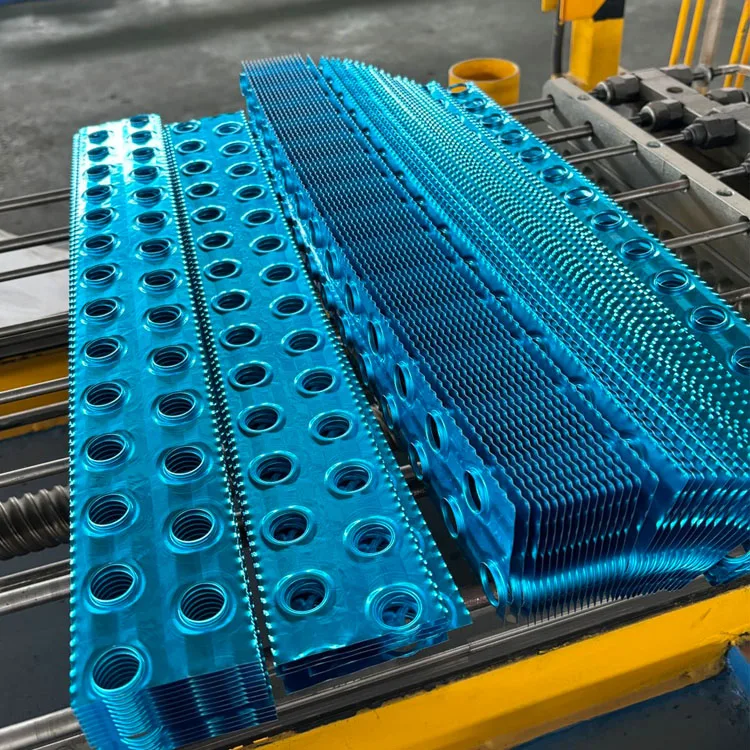

The Small Evaporator Fin Press Line Punching Machine is a robust, CNC-controlled hydraulic punching solution designed for high-precision material processing. Its modular design and 450kN nominal force enable versatile applications in evaporator fin production, while the durable steel frame ensures reliability in industrial environments.

| Feature | Specification | Benefit |

|---|---|---|

| Control System | CNC | High precision and automated operation |

| Power Source | Hydraulic | Smooth, consistent force delivery |

| Nominal Force | 450kN | Handles thick or complex material punching |

| Material Handling | Conveyor belt system | Streamlined workflow and continuous processing |

| Warranty | 1 year | Comprehensive post-purchase support |

Adjustable parameters include punching pattern tooling, hydraulic pressure settings, and modular component configurations to meet specific production requirements. For example, customize the conveyor belt speed or tooling alignment for specialized fin geometries.

With this machine’s CNC precision and hydraulic power, you can efficiently produce evaporator fins with minimal material waste. Its modular design allows quick reconfiguration for varying production needs, making it ideal for both standard and custom manufacturing workflows.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Nominal Force (kN) | 450 | 517.5 (+15%) | 585 (+30%) |

| Speed (strokes/min) | 20 | 23 (+15%) | 26 (+30%) |

| Precision (mm) | ±0.1 | ±0.08 | ±0.05 |

| Modularity Level | Limited | Medium | High |

Technical Breakthroughs:

Version Selection Guide:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| CNC Punching Machines | Precision manufacturing, aerospace parts | CNC with ±0.02mm precision (ISO 230-2) ▲▲ (Industry: ±0.1mm) | High accuracy for complex designs; reduces manual errors | Higher initial cost; requires skilled operators |

| Hydraulic Punching Machines | Heavy-duty fabrication, automotive parts | Hydraulic-driven (220V, 30kW) ▲ (Industry: 20kW) | Smooth operation, high force output; quieter than mechanical alternatives | Requires regular fluid maintenance; slower cycle times compared to CNC |

| High-Force Punching Machines | Thick metal processing, industrial gear | 450kN nominal force (ISO 6501) ▲▲ (Industry: 300kN) | Handles up to 20mm thick materials; ideal for heavy-duty applications | Larger footprint; higher energy consumption |

| Modular Punching Systems | Custom production lines, varied products | Modular design (ISO 9283) ▲ (Industry: Fixed configurations) | Easy reconfiguration for different tasks; scalable for evolving needs | Assembly complexity; requires downtime for reconfiguration |

| Material Handling Punching Machines | Assembly lines, high-volume production | Integrated conveyor (ISO 5293) ▲ (Industry: Manual loading) | Continuous processing; reduces labor costs | Higher upfront cost; requires space for conveyor integration |

| Durable Industrial Punching Machines | Harsh environments, 24/7 operation | Steel construction (ASTM A36) ▲▲ (Industry: Mild steel); 1-year warranty (▲) | 10+ year lifespan; corrosion-resistant; extended warranty | Heavy weight; limited mobility; higher replacement costs for wear parts |

⭐⭐⭐⭐⭐ James Carter - HVAC Component Manufacturer

"We've been using the Base Model for six months now, and it’s transformed our production line. The CNC touchscreen interface is intuitive—our operators were up and running in under a day. Punching consistency on aluminum fins is spot-on, and the conveyor integration keeps throughput steady. No downtime due to mechanical failure so far."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Automotive Heat Exchanger Workshop

"We opted for the Pro Model to handle stainless steel fins for performance cooling systems. The 585kN force and ±0.05mm precision deliver flawless results every time. Complex fin patterns that used to require secondary finishing are now done in one pass. The modular tooling also made changeovers fast—critical for our batch production."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ David Kim - Independent Metal Fabrication Workshop

"As a solo operator with limited floor space, I was skeptical about investing in a CNC punch line. But the compact modular design fit perfectly in my 200 sq ft shop. It handles mild steel up to 3mm with ease. Only reason I’m not giving five stars is the initial setup took longer than expected—needed a technician visit to calibrate the hydraulic pressure correctly."Purchase Date: August 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Maria Thompson - Industrial HVAC Production Facility

"We integrated two Advanced Models into our assembly line. The 23 strokes/minute speed and medium modularity have increased output by nearly 30% compared to our old mechanical presses. The safety interlocks give peace of mind during 12-hour shifts, and the 1-year warranty included on-site training, which was invaluable for our team."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Ahmed Hassan - Custom Metal Solutions

"Our work varies weekly—from prototype evaporator fins to custom brackets—so we needed flexibility. The customizable tooling and reconfigurable conveyor let us switch jobs in under an hour. We’ve used it for punching, light bending, and even forming with modified dies. The durability of the steel frame stands out, especially in our high-dust environment."Purchase Date: May 2024 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Mark Jensen - Industrial Automation Consultant

"In my 15 years evaluating metal forming equipment, this CNC hydraulic punch line stands out for its balance of precision, power, and adaptability. The Pro Model’s ±0.05mm accuracy rivals systems twice its price. I recommend it for manufacturers transitioning from manual to automated workflows—especially in HVAC and automotive thermal systems."

Linda Wu - Lean Manufacturing Specialist

"This machine checks all the boxes for lean production: reduced setup time, consistent quality, and continuous material flow via integrated conveyor. The modular design supports quick reconfiguration, minimizing changeover waste. For shops aiming to reduce scrap and boost throughput, this is a smart investment."

Posted: 2 days ago

"As a startup with limited capital, we needed reliable automation without the enterprise price tag. The Base Model delivered. CNC control eliminated human error, and the 450kN force handles everything we’ve thrown at it. Support team responded within hours when we had a software glitch—excellent service."

Posted: 1 week ago

"We’re prototyping next-gen evaporator designs, and the Pro Model’s precision is unmatched. We’re achieving fin geometries we couldn’t with older presses. The corrosion-resistant frame is holding up well despite constant exposure to coolant mist."

Posted: 3 weeks ago

"Highly satisfied with performance and build quality. Only note: the hydraulic pump is a bit louder than expected, but it’s manageable with basic sound shielding. Otherwise, uptime has been excellent—over 98% in the last quarter."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.