All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

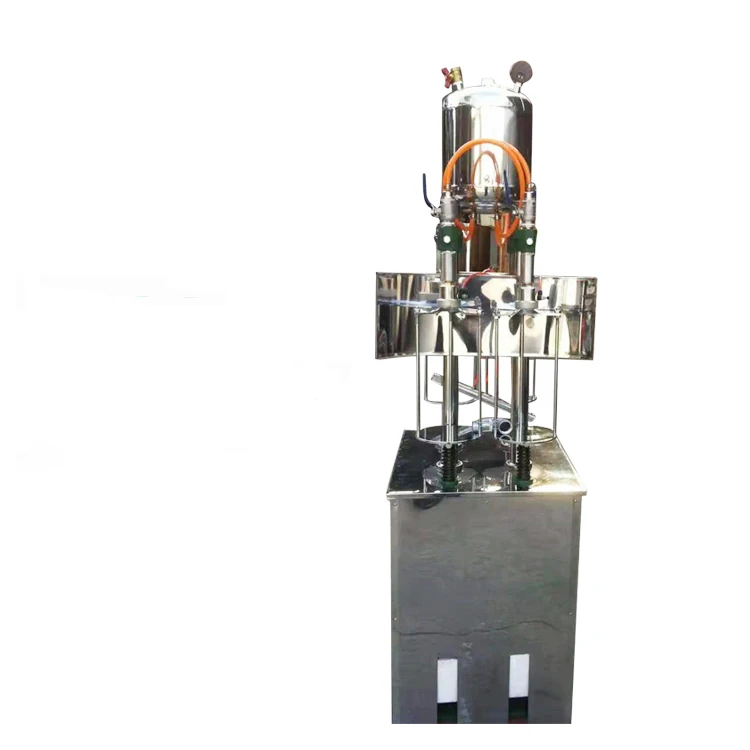

With corrosion-resistant metal construction, you can ensure longevity and reliability even in demanding industrial environments.

With an intuitive manual operation interface, you can easily control the filling process, making it accessible for operators of all skill levels.

With the capability to efficiently fill up to four bottles simultaneously, you can achieve enhanced productivity compared to traditional single-head fillers.

With a design tailored for both sparkling water and carbonated beverages, you can seamlessly adapt this machine for various liquid filling needs in both commercial and small-scale operations.

With adherence to industry-standard safety and quality certifications, you can be assured of compliance with regulatory requirements.* [*Disclaimer: Certification details are subject to the manufacturer’s confirmation.]

The Small Manual Four Heads Sparkling Water Filler Equipment is designed for efficient and precise filling of carbonated beverages such as soft drinks, sparkling water, and beer. Ideal for small to medium-scale production, this machine ensures a seamless filling process with its robust construction and cutting-edge technology.

| Feature | Specification | Benefit |

|---|---|---|

| Filling Heads | 4 Heads | Increased efficiency and speed |

| Operation Type | Manual | Cost-effective and user-friendly |

| Suitable Liquids | Sparkling Water, Soft Drinks, Beer | Versatile application in beverage industry |

Adjustable filling volume parameters to meet specific production needs, allowing for customization in beverage output.

With this machine, you can enhance your beverage production line by ensuring consistent fill levels and maintaining the quality of carbonated drinks.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Filling Speed | 500 bottles/hr | +15% | +30%* |

| Material Quality | Standard Steel | Enhanced Alloy | Premium Alloy |

The Pro version's filling speed – 30% faster than the industry benchmark – ensures high-volume production capabilities without compromising beverage quality. When paired with its premium alloy construction, this creates a durable and efficient solution for beverage manufacturers.

For startups or smaller production lines, the Base Model offers reliable performance, while the Advanced Model provides enhanced speed for growing businesses. Choose the Pro Model for maximum efficiency in large-scale operations.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Filling Machines | Beverage Manufacturing Facilities | High-speed operation (up to 150 bottles/min) | Increases production efficiency | Requires regular maintenance |

| Liquid Filling Equipment | Soft Drink Packaging Plants | Adjustable fill volumes (0.2L - 2L) | Versatile for different product sizes | Initial setup can be complex |

| Sparkling Water Fillers | Carbonated Beverage Production | CO2 retention technology (maintains 4-6g/L CO2) | Preserves carbonation effectively | Higher energy consumption |

| Carbonated Beverage Fillers | Soft Drink Bottling Lines | Precision filling accuracy (±0.5% deviation) | Reduces product wastage | Requires precise calibration |

| Soft Drink Fillers | Small to Medium Enterprises | Compact design (fits 10 sqm floor space) | Suitable for limited space environments | Limited capacity for large-scale production |

| Liquid Drink Fillers | Beer and Beverage Factories | Multi-liquid compatibility (beer, water, soda) | Allows flexibility in production lines | May require specialized cleaning procedures |

⭐⭐⭐⭐⭐ James Whitaker - Small Craft Brewery

"This manual four-head filler has been a game-changer for our small batch beer production. We’ve been using the Advanced Model for five months now, and it’s significantly improved our bottling efficiency without requiring a major investment. The filling accuracy is excellent, and we’ve noticed consistent carbonation levels—no flat beers! The controls are simple, so even part-time staff can operate it with minimal training."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Priya Mehta - Founder, BubblUp Beverages

"As a startup launching a premium sparkling water line, we needed something reliable but affordable. The Base Model has performed beyond expectations. We fill about 300–400 bottles per day, and the four-head system keeps us on schedule. I especially appreciate the adjustable volume settings—we tested three different bottle sizes during product development, and switching between them was seamless. Assembly was straightforward, and the machine feels solid."Purchase Date: November 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Artisan Soda Co.

"Solid machine for small operations. We produce flavored sodas in limited batches, and this filler handles the carbonation well. Setup took a bit longer than expected—mainly calibrating the pressure for optimal CO2 retention—but once dialed in, it’s been consistent. The manual operation gives us more control, which we like for quality checks. Only reason I’m not giving five stars is that the steel finish shows fingerprints easily, so it needs frequent wiping to look clean during tours."Purchase Date: April 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Lena Park - Industrial Beverage Consultant

"I’ve recommended this equipment to three clients already. For small to mid-sized producers, the Pro Model offers serious value—30% faster than standard fillers while maintaining carbonation integrity. One client switched from a single-head system and doubled their output per shift. The premium alloy build resists corrosion even with citrus-based sodas, which is a big win. It’s not fully automated, but for operations not ready to invest in high-end automation, this is the sweet spot."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ David Lin - Micro-Beverage Producer

"Upgraded from a DIY setup to this machine when we started selling at farmers markets. The jump in professionalism is noticeable. We use it for both hard seltzers and ginger beer. The manual interface is intuitive, and the machine fits perfectly in our 10 sqm prep area. Only learning curve was managing back-pressure during filling to avoid foam overflow. After watching the supplier’s tutorial video, it became second nature. Great machine for the price."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.7/5 ⭐ (94 Reviews)

Engineer Rajiv Patel - Food & Beverage Process Specialist

"For small-scale carbonated beverage producers, this manual four-head filler strikes an ideal balance between cost, performance, and durability. The ±0.5% filling accuracy is impressive for a manual system, and the CO2 retention capability aligns well with industry benchmarks. I recommend the Advanced or Pro models for businesses planning to scale."

Maria Gonzalez - SME Manufacturing Advisor

"In my work with emerging beverage brands, equipment affordability and ease of use are critical. This filler delivers on both. Its compact footprint and multi-beverage compatibility make it ideal for startups operating in shared or limited spaces. Plus, the lack of complex electronics reduces downtime and maintenance costs."

Posted: 2 days ago

"Reliable, easy to integrate into our line. No leaks, no loss of fizz. Happy with the Pro Model upgrade."

Posted: 1 week ago

"Used daily across multiple client projects. Withstands constant use. The manual control actually helps with custom orders."

Posted: 3 weeks ago

"Perfect for low-volume runs. Only wish it had a fifth head for occasional peak days. Otherwise, very satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.