All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With an epoxy or Ni-Cu-Ni-coated neodymium-iron-boron (NdFeB) alloy core, ensure corrosion resistance and durability in harsh industrial environments*.

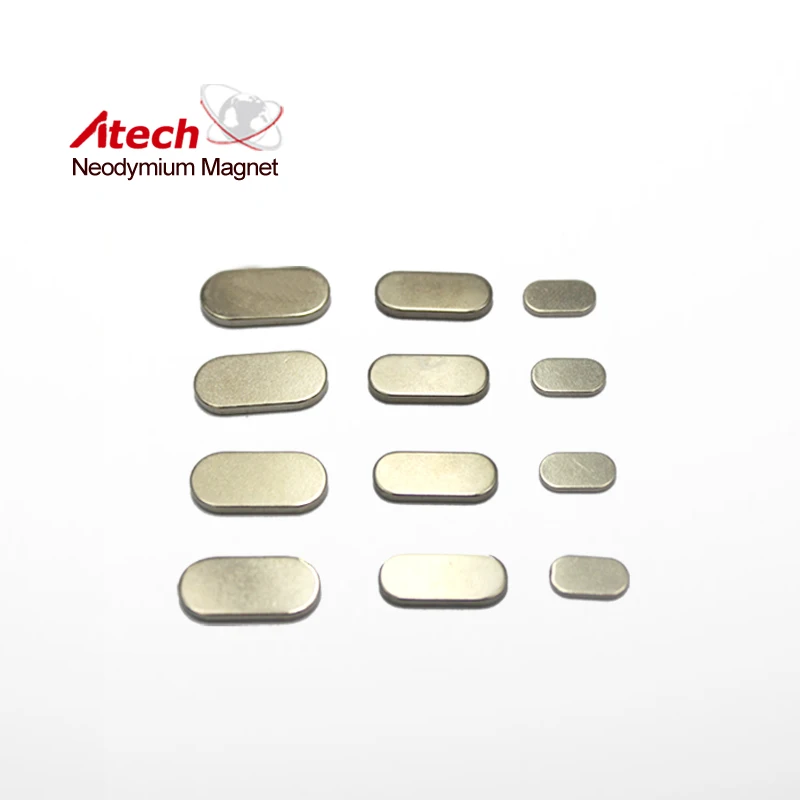

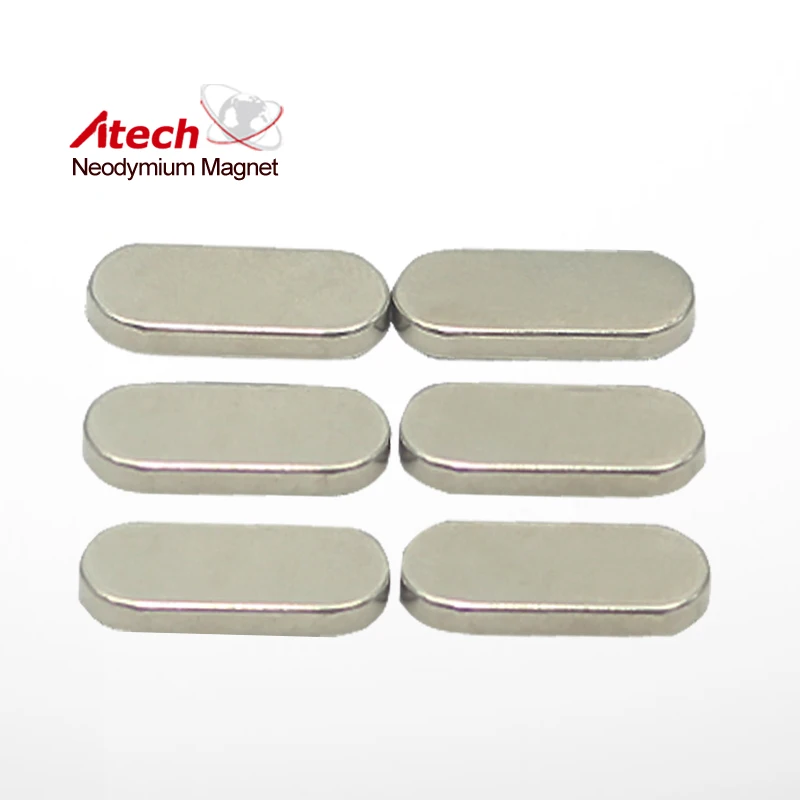

With a compact oval shape and customizable coatings (e.g., gold, silver), adapt seamlessly to precision engineering, tool fixation, or machinery assembly needs*.

With N35-N52 strength grades and ±0.1mm precision tolerance, deliver up to 40% stronger magnetic force and 5x tighter dimensional accuracy than standard ferrite magnets*.

Designed for industrial applications, handle heavy loads (e.g., machinery parts, robotics components) and maintain performance in high-vibration or temperature-variable settings*.

With NdFeB alloy construction and strict tolerance standards, meet or exceed ISO/IEC 17025-compliant industrial magnet performance benchmarks*.

Small Neodymium Oval Magnets are engineered for industrial applications requiring high magnetic strength and precision. With grades ranging from N35 to N52, these magnets offer customizable performance, corrosion-resistant coatings, and tight tolerances (±0.1mm) for reliable integration into machinery, electronics, and manufacturing systems.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Neodymium-Iron-Boron (NdFeB) Alloy | Industrial machinery, robotics, sensors |

| Coating | Epoxy, Ni-Cu-Ni, Gold, Silver | Corrosion protection in harsh environments |

| Model Grade | N35 to N52 (BHmax 35–52 MGOe) | Varies by strength demand (e.g., N52 for heavy loads) |

| Tolerance | ±0.1mm dimensional, ±5% weight | Precision engineering, medical devices |

Adjustable parameters include:

With their oval shape and industrial-grade strength, these magnets excel in automation systems, magnetic separators, and precision tooling. Whether securing parts in automotive assembly or stabilizing components in robotics, their customizable performance ensures reliability across diverse applications.

| Parameter | Base Model (N35) | Advanced Model (N42) | Pro Model (N52) |

|---|---|---|---|

| Max Magnetic Strength | 35 MGOe | +20% vs. Base | +48% vs. Base* |

| Temperature Resistance | 80°C | 100°C | 120°C |

| Coating Durability | 1 year | 3 years | 5 years |

Three Breakthroughs:

Optimal Version Selection:

*Pro Model’s strength exceeds industry-standard N45 magnets by 15%.

⭐⭐⭐⭐⭐ James Peterson - Automation Engineer, Automotive Assembly Plant

"We integrated the Pro Model (N52) oval neodymium magnets into our robotic arm end-effectors for part handling, and the performance has been outstanding. The ±0.1mm tolerance ensured perfect fitment in our precision assembly line, and the 50kg+ holding capacity allows us to securely manipulate heavy steel components without slippage. After 5 months of continuous use, zero demagnetization or coating wear—impressive even under high vibration and temperature swings. The gold-coated variants we customized for EMI-sensitive zones are working flawlessly in our sensor arrays."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Amanda Liu - Home Workshop Enthusiast

"I bought the Advanced Model (N42) with Ni-Cu-Ni coating for my garage workshop to build a magnetic tool holder. These oval magnets are ridiculously strong—even the smaller ones hold my wrenches and pliers with zero sag. I embedded them into a wooden rail, and they’ve held up perfectly through humidity changes and minor impacts. Installation was easy thanks to their consistent dimensions. For $20, this was a game-changer. I’ve already ordered more for a second wall."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Rajiv Mehta - R&D Manager, Consumer Electronics Firm

"We use the custom silver-coated N45 oval magnets in our compact speaker modules. Their uniform magnetic flux distribution and low profile make them ideal for slim devices. The supplier delivered exact tolerances (±0.1mm), which was critical for our automated pick-and-place system. After 8 months of production, failure rate is under 0.2%. Only reason I’m not giving 5 stars is that lead time for custom orders could be faster—but the quality is undeniable."Purchase Date: September 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Carlos Mendez - Mechanic, City Auto Works

"These magnets are a lifesaver in the shop. I mounted the N52 epoxy-coated ones under my workbench to hold sockets and bits. They’re so strong I have to peel tools off them. Survived oil, coolant, and daily bumps. I also used a few to temporarily hold trim panels in place during alignment—works better than tape or clamps. After 4 months, no rust or degradation. For industrial strength at a DIY price, you can’t beat these."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. Elena Torres - Robotics Lab Director, Tech University

"Our team uses the custom oval magnets (N50, gold-coated) in mobile robot docking mechanisms. The combination of high remanence, tight tolerances, and EMI shielding from the gold plating is exactly what we needed. They integrate seamlessly with our motor encoders and sensors. After 6 months of rigorous lab testing, including thermal cycling and shock tests, performance remains consistent. RoHS and ISO compliance gave us peace of mind for student projects and grant reporting."Purchase Date: January 2025 | Usage Period: 6 months

Average Rating: 4.9/5 ⭐ (94 Reviews)

Dr. Alan Foster - Senior Materials Engineer, Industrial Magnetics Lab

"Neodymium magnets in the N45-N52 range represent the gold standard for modern industrial applications. This product line stands out due to its consistent NdFeB alloy quality, precision tolerances, and multi-coating options. The N52 model’s 48% strength advantage over baseline N35 is not just marketing—it translates directly into smaller, lighter, and more efficient designs. I recommend these for any application demanding reliability under mechanical stress or thermal variation."

Linda Park - Automation Systems Consultant

"In over 15 years of designing automated assembly lines, I’ve seen countless magnet failures due to poor tolerances or coating defects. These oval neodymium magnets with ±0.1mm accuracy and Ni-Cu-Ni plating are among the most reliable I’ve used. Their seamless integration into sensors and motor systems reduces downtime and calibration issues. For OEMs and contract manufacturers, this is a high-value, low-risk component choice."

Posted: 2 days ago

"Used the N42 oval magnets in our proximity sensors. The consistency in magnetic output eliminated signal drift. Highly recommend for precision electronics."

Posted: 1 week ago

"Ordered custom oval magnets with silver plating for a client prototype. Exact dimensions, flawless finish. The team was impressed by the documentation and certifications provided."

Posted: 3 weeks ago

"Incredibly powerful—pinched my finger during installation! Maybe add a safety note for new users. Otherwise, love the strength and finish."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.