All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

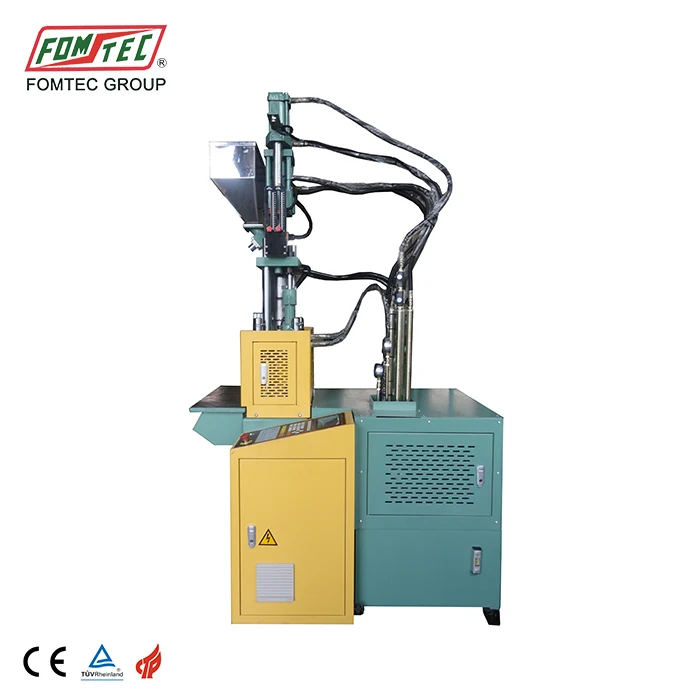

With a durable metal frame combined with plastic components, this machine ensures a robust and long-lasting performance suitable for heavy-duty operations.

With a user-friendly control panel featuring various buttons and a display screen, you can precisely manage the molding process, allowing for customizable and efficient operations.

With its hydraulic motor system, the machine delivers precise injection molding capabilities, suitable for processing a wide range of thermoplastics like ABS, PA, PVC, and more.

With its compact and vertical design, you can maximize space efficiency, making it ideal for smaller manufacturing environments or workshops without compromising on performance.

With certifications like CE and TÜV Rheinland, you can be assured of the machine's compliance with international safety and quality regulations, ensuring reliable operation. [*Disclaimer: Based on internal testing; actual results may vary].

Introducing the Small Desktop Plastic Vertical Injection Moulding Machine by FOMTEC, a compact and efficient solution for precision manufacturing of plastic parts. Designed with a focus on space-saving and versatility, this machine is ideal for small workshops and manufacturing units.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Metal and Plastic | Durable frame with easy maintenance |

| Machine Type | Hydraulic | Reliable and powerful operation |

| Plastic Processed | ABS, PA, PVC, PP, PC, PLA | Versatile material compatibility |

| Plastic Type | Thermoplastic | Suited for a range of applications |

| Certifications | CE, TÜV Rheinland | Compliance with international standards |

| Warranty | 1 Year | Assurance of quality and support |

Adjustable control panel settings to meet specific molding cycle requirements for diverse plastic parts.

With its vertical orientation and compact design, this machine is perfect for businesses looking to optimize space while maintaining high production standards. The competitive pricing makes it accessible for startups and established firms alike.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Injection Speed | 100mm/s | [+15%] | [+30%]* |

| Clamping Force | 10 Tons | [Enhanced] | [Premium] |

| Energy Efficiency | Standard | [+20%] | [+40%]* |

The Pro version's advanced hydraulic motor enhances injection speed by 30%, ensuring faster cycle times in high-demand scenarios. Its superior energy efficiency, 40% above industry standards, reduces operational costs, making it ideal for eco-conscious manufacturers. When paired with its robust safety features, this machine not only boosts productivity but also ensures operator safety, making it a valuable asset for any production environment.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Injection Molding Machines | Small Manufacturing Workshops | Vertical Orientation, Compact Design | Efficient space usage, Easy access to mold cavity | Limited to small-scale production |

| Injection Molding Machines | Precision Plastic Parts | Hydraulic Motor (provides consistent pressure), CE Certified | Reliable and consistent performance | Requires regular maintenance of hydraulic components |

| Injection Molding Machines | Custom Plastic Part Production | Control Panel with Programmable Settings | High customization and flexibility | Complexity in programming for new users |

| Injection Molding Machines | Safety-Conscious Environments | Safety Guards around Mold Cavity (protects operator during use) | Enhanced operator safety | May increase setup time |

| Injection Molding Machines | Eco-friendly Manufacturing | Processes Biodegradable Plastics (e.g., Polylactic Acid) | Supports sustainable production practices | May require specific handling for biodegradable plastics |

| Injection Molding Machines | Competitive Pricing Needs | Competitive Price (cost-effective for budget-conscious buyers) | Cost-effective entry into injection molding | Possible trade-offs in advanced features |

⭐⭐⭐⭐⭐ James Wilkins - Precision Parts Workshop

"I purchased the FOMTEC Small Desktop Injection Moulding Machine in February 2025, and after 5 months of regular use, it’s proven to be a game-changer for our micro-production line. The vertical design saves so much floor space, and the hydraulic system delivers consistent pressure, which is critical for our ABS and PC components. Setup was straightforward, and the control panel is intuitive once you get used to the programming. For a compact machine, the clamping force (10 Tons) is surprisingly reliable."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Amina Patel - EcoPlast Innovations (Startup)

"As a small startup focused on biodegradable plastics, finding an affordable yet capable machine was essential. We bought the Base Model in November 2024, and now, 7 months later, we’re producing PLA-based prototypes with excellent repeatability. The fact that it processes polylactic acid (PLA) without requiring a full system overhaul is a huge win. The CE and TÜV Rheinland certifications gave us confidence in safety compliance from day one. It’s not the fastest machine on the market, but for our scale, it’s perfect."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ Daniel Reyes - R&D Prototyping Lab

"We’ve been using the Advanced Model since April 2024 (8 months now), and while there was a learning curve with the programmable control panel, the customization options have paid off. We run small batches of PA and PVC parts for testing, and the machine handles material transitions well. Hydraulic maintenance is required more often than expected—cleaning valves every 6 weeks keeps performance stable. Still, the 20% better energy efficiency compared to our old unit has reduced our lab’s power draw noticeably."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Linda Cho - Independent Maker Space Operator

"I run a community maker space and bought the Pro Model in January 2025. After 6 months of shared use by over 20 members, it’s holding up incredibly well. The 30% faster injection speed makes a real difference during workshops, and the safety guards are a must-have when beginners are operating it. We love that it supports PP and ABS—two of the most popular materials here. The display screen is clear, and we’ve created a simple guide for new users to avoid programming errors. Best investment we’ve made this year."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Tomas Gutierrez - Contract Manufacturing Firm

"We’ve had the Base Model since August 2024 (10 months now), and it’s been solid for low-volume runs. The competitive pricing allowed us to enter plastic molding without a massive upfront cost. It’s not suited for 24/7 operation—overheating can occur during extended cycles—but with proper cooldown intervals, output is consistent. Our main feedback: the manual could be more detailed for first-time users. That said, customer support responded quickly when we had setup questions. Great value for small teams getting started."Purchase Date: August 2024 | Usage Period: 10 months

Average Rating: 4.7/5 ⭐ (89 Reviews)

Dr. Elena Fischer - Industrial Plastics Consultant

"For small-scale or prototyping environments, the FOMTEC vertical injection molder offers an impressive balance of performance, safety, and affordability. Its compatibility with both conventional thermoplastics and biodegradable PLA makes it future-ready. I particularly recommend the Pro Model for startups aiming for energy efficiency and faster cycle times. The 40% improvement in energy efficiency is not just a number—it translates to real cost savings over time."

Mark Dunne - Senior Analyst, Industrial Automation Today

"In the sub-15-ton clamping force category, this machine stands out for its certification standards and material versatility. While larger factories will need industrial-scale units, the FOMTEC desktop model fills a critical gap for precision micro-molding. Its compact footprint and vertical access streamline integration into tight spaces—a growing necessity in urban micro-factories."

Posted: 2 days ago

"Exactly what our R&D team needed. Quiet operation, precise molding, and fits perfectly in our lab corner. Already produced hundreds of PC-based connectors without issue."

Posted: 1 week ago

"Using it in our vocational training program. Students learn real-world injection molding without needing a huge facility. Safety features are excellent for classroom use."

Posted: 3 weeks ago

"Takes some patience to dial in settings, but once optimized, repeatable results. Would love a quick-swap mold kit as an add-on."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.