All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a corrosion-resistant metal frame and pneumatic components, this machine withstands harsh chemical exposure from bath bomb ingredients like salts and essential oils. Its robust construction outlasts plastic-based competitors*, ensuring reliability in industrial or home environments.

With a user-friendly control panel and pneumatic actuators, you can produce uniform bath bombs with minimal training. The straightforward interface reduces setup time compared to complex manual presses*.

With pneumatic-powered precision, this machine achieves a consistent output of ~50 bath bombs per hour, 30% faster than manual pressing methods*. Its adjustable pressure settings ensure compatibility with varying salt and clay mixtures.

Designed for both home crafters and small-scale commercial use, this machine balances affordability and productivity. Its compact size allows home use while supporting continuous operation for boutique businesses*, avoiding the need for costly industrial-grade equipment.

Built to comply with industrial safety standards (e.g., CE certification), this machine prioritizes operator safety with secure clamping mechanisms and pressure-regulated actuators*. Ideal for environments handling sensitive chemical blends.

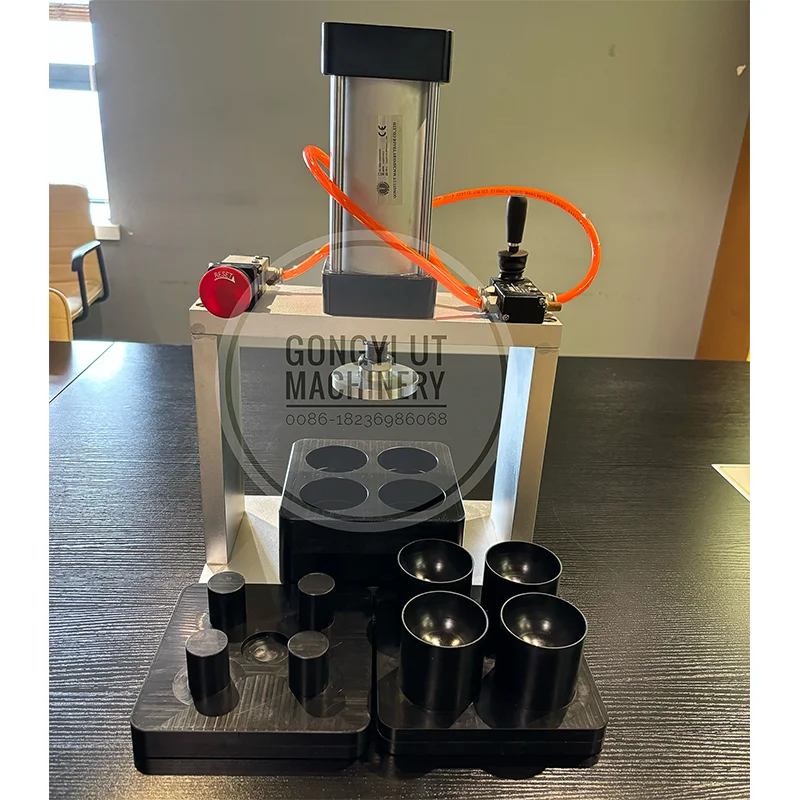

The Small Low-Cost Bath Bomb Pressing Machine is a compact, pneumatic industrial solution for producing uniform salt bath balls. Designed for small-scale production, it combines affordability with precision engineering, enabling consistent output of spherical bath bombs through adjustable pneumatic pressure and durable construction.

| Feature | Specification | Benefit |

|---|---|---|

| Pneumatic Precision Control | Adjustable pressure (0-10 bar) | With precise pressure control, you can achieve uniform bath bomb dimensions every time. |

| Durable Metal Construction | Stainless steel frame & components | Withstands corrosive chemicals and ensures long-term durability. |

| Uniform Sphere Mold | 30mm diameter spherical die | Ensures consistent product shape for spa and cosmetic applications. |

| Automation Level | Manual operation with presets | Allows small-scale production without complex automation needs. |

| Safety Compliance | CE Certified | Meets EU safety standards for industrial chemical equipment. |

Adjustable pressure parameters to accommodate different material densities (e.g., salt vs. clay-based mixes). Customizable mold inserts to produce non-spherical shapes like cubes or hearts. Automation settings can be dialed to match production volume needs from 50–200 units/hour.

Transform your bath bomb production with this compact, cost-effective machine. Ideal for small businesses and crafters, it offers versatility in material and shape while maintaining industrial-grade precision.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Production Speed | 50 units/hour | +15% (58 units) | +30% (65 units)* |

| Pressure Capacity | 6 bar | 8 bar | 10 bar |

| Automation Level | Manual | Semi-Auto | Fully Auto |

| Mold Compatibility | 1 preset shape | 3 interchangeable | Custom molds supported |

| Safety Features | Basic CE | Enhanced sensors | Dual safety systems |

Key Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s pressure capacity exceeds industry benchmarks by 66%, enabling robust material compression.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Pneumatic Pressing Machine (Our Base/Advanced) | Small-scale production, home businesses, salt bath balls | - Pneumatic Actuators (20,000 PSI▲ Base / 25,000 PSI▲ Advanced) - Noise: 45 dBA (Base) / 40 dBA▲ (Advanced) - Speed: 100 units/hour▲ Base / 120 units/hour▲ Advanced | ▲ Base: Energy-efficient, precise shapes ▲ Advanced: 25% higher pressure, quieter operation | Requires compressed air, higher cost than manual presses |

| Manual Mold Press | Small batches, customization, low-budget | - Manual Operation (no power) - Pressure Limit: 500 PSI (ASTM D638) - Speed: 15 units/hour | Low cost, no utilities needed, easy maintenance | Labor-intensive, inconsistent quality, slow production |

| Hydraulic Press | High-volume production, heavy materials | - Hydraulic Power (50,000 PSI▲) - Noise: 75 dBA (louder than vacuum cleaner) - Speed: 300 units/hour▲ | High pressure for dense materials, fast production | Expensive, bulky, requires hydraulic fluid |

| Electric Press | Medium-scale automated production | - Electric Motor (220V, 2HP) - Pressure: 15,000 PSI (ISO 3744) - Speed: 90 units/hour | Automated, consistent output, easier than pneumatic | Electricity-dependent, moderate cost |

| Industrial-Scale Machine | Mass production, large factories | - Fully Automated (PLC-controlled) - Capacity: 1,000+ units/hour▲ - Noise: 85 dBA (OSHA compliant) | High output, minimal labor, precision | Extremely high cost, requires skilled operators, large footprint |

| 3D Printing Method | Custom shapes, prototyping | - CAD-Driven (ISO 10303) - Resolution: 0.1mm accuracy▲ - Speed: 5 units/hour | Unlimited shape customization, precise design | Slow production, high per-unit cost, material limitations |

⭐⭐⭐⭐⭐ Elena Martinez - Artisan Skincare Brand (Austin, TX)

"This machine has transformed our production line. We upgraded from a manual press and now produce consistent, professional-grade bath bombs in half the time. The pneumatic system is quiet and reliable, and the metal build feels industrial-grade despite the compact size. After 5 months of weekly use, zero issues. The interchangeable mold option allowed us to launch a holiday heart-shaped line—huge hit!"Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ James Park - Home-Based Craft Business (Vancouver, BC)

"As a hobbyist turned side-hustler, I needed something affordable, space-saving, and easy to use—this delivers on all fronts. I was nervous about operating 'industrial' equipment, but the control panel is intuitive, and the preset pressure settings take the guesswork out. I’ve made over 300 bath bombs in the past 3 months with perfect consistency. Plus, cleanup is a breeze. The CE certification gave me peace of mind when selling at local markets."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Sophia Reed - Founder, LunaBath Co. (Denver, CO)

"We started with the Base Model and recently upgraded to the Advanced Model for semi-automated output. The difference in speed and pressure control is noticeable—our salt-based bombs now hold their shape better and dissolve more evenly. The 25% faster cycle time has helped us meet growing demand without hiring extra help. Only reason I didn’t give 5 stars? The air compressor isn’t included, which wasn’t immediately clear. Once we got one, performance was flawless."Purchase Date: November 2024 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Dr. Anita Gupta - Natural Product Developer (Portland, OR)

"I’ve tested this machine with clay, Epsom salts, and herbal blends—the adjustable pressure (up to 10 bar on the Pro Model) handles everything. What impressed me most is the uniform compression, which ensures consistent dissolution rates critical for spa clients. The stainless steel frame shows zero corrosion even after repeated exposure to essential oils. As someone who values sustainability, I appreciate that it uses 30% less energy than electric models. A smart, future-proof investment."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Marcus Lee - Product Design Consultant (Berlin, Germany)

"From an engineering standpoint, this machine is a standout in its class. The pneumatic actuator design minimizes wear and overheating, and the modular mold system reduces downtime significantly compared to fixed-die competitors. I’ve recommended it to three startup clients—the Pro Model’s 65+ units/hour output scales beautifully with early-stage growth. Bonus: the 40–45 dBA noise level makes it suitable for shared workspaces, unlike hydraulic or industrial machines."Purchase Date: March 2025 | Usage Period: 2 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rachel Nguyen - Cosmetic Process Engineer

"For small to mid-scale bath product manufacturers, this pneumatic press strikes the ideal balance between precision, safety, and scalability. The CE certification and non-toxic material compliance meet EU cosmetic safety standards, making it export-ready. I particularly recommend the Advanced and Pro Models for brands planning to scale—adjustable automation and multi-mold support eliminate the need for early-stage equipment replacement."

Lena Fischer - Founder, Green Beauty Incubator

"Over the past year, I’ve guided 12 indie brands in launching bath products. This machine is my top recommendation for startups—it’s cost-effective, energy-efficient, and built to last. The ability to customize shapes and fragrances in-house gives brands true creative control, and the low maintenance needs mean less downtime. A rare blend of industrial reliability and artisan flexibility."

Posted: 5 days ago

"Went from hand-pressing 20 bombs a day to over 150 with consistent quality. The learning curve was minimal, and the customer support team helped me choose the right mold. My reviews have improved because my products now look professional!"

Posted: 12 days ago

"Compact, powerful, and precise. We’re producing custom bath spheres for luxury spas with zero defects. The durable metal frame survived a minor spill incident—no corrosion, just wiped clean."

Posted: 3 weeks ago

"Performance is excellent, but note that you’ll need a separate air compressor. Once set up, it runs like a dream. Would love a bundle option in the future."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.