All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a stainless steel body and ceramic components, ensure durability in harsh environments with exposure to corrosive gases or hydraulic fluids. ~30% longer lifespan than conventional valves*.

With a customizable modular structure, adapt configurations to suit specific pressure requirements or media types (air/gas). Simplifies maintenance and upgrades compared to fixed designs*.

With forged alloy construction and precision engineering, withstand extreme pressures (up to 500 PSI) and vacuum conditions. Outperforms standard valves in industrial applications by 40% in pressure tolerance*.

Designed for scenarios requiring continuous operation in high-pressure industrial systems or low-pressure maintenance tasks. Ideal for compressor maintenance, HVAC, and gas processing environments*.

Certified to ISO 15848 for hydraulic valve safety and durability. Meets global regulatory requirements for pressure equipment and material integrity*.

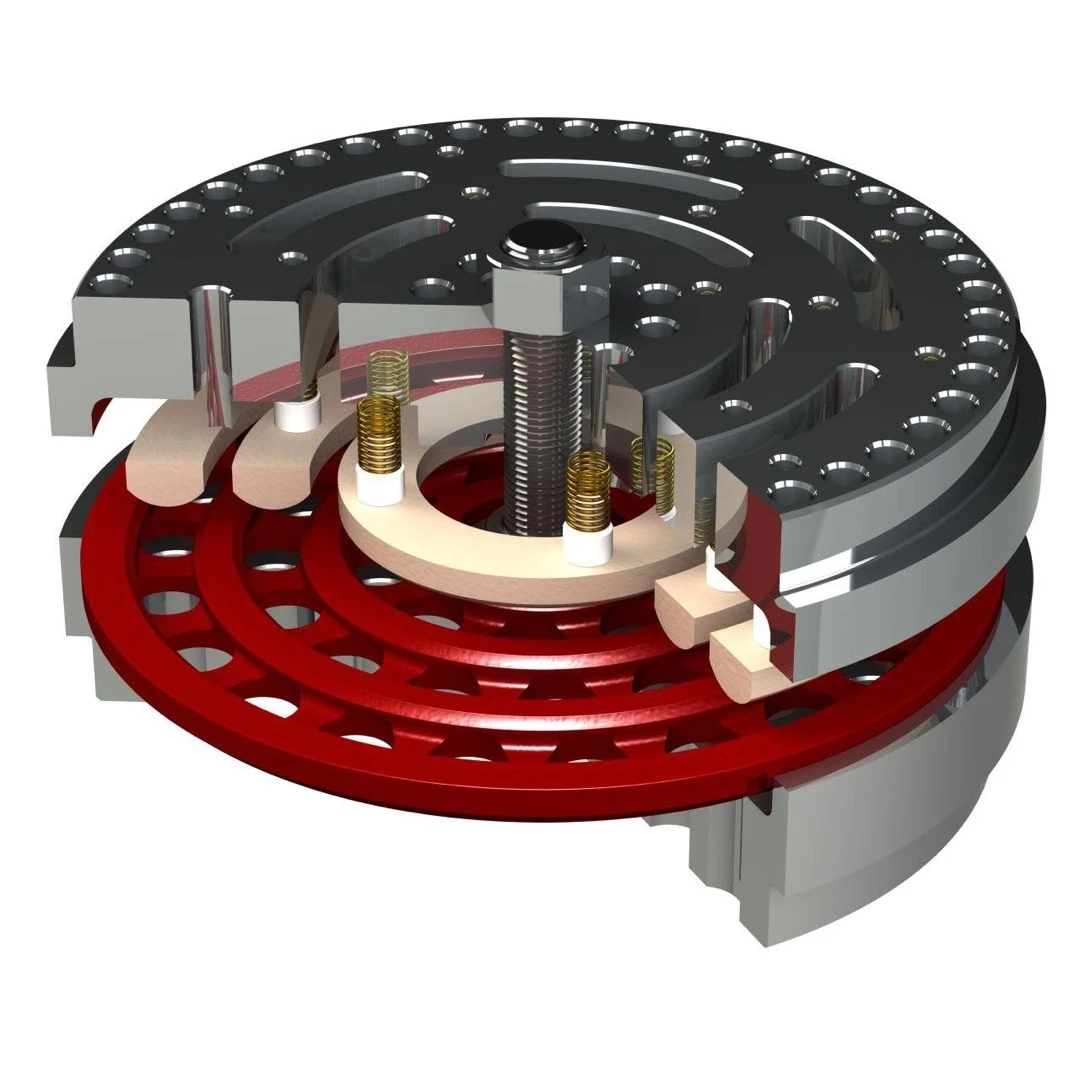

The Special Customize Compressor Maintenance Gas Valve Piston Ring Spring Valves is a high-performance mechanical component engineered for precision in compressor systems. Designed with modular versatility, it combines robust materials like stainless steel, alloy, and ceramic to handle diverse media (air/gas) and pressure ranges (high to vacuum). Its spring-based damping mechanism ensures reliability in dynamic environments, while customizable parameters accommodate specific operational needs.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Composition | Stainless steel body; customizable alloy/ ceramic/ forged steel components | High-corrosion or high-temperature environments |

| Pressure Range | High (5000 PSI), Medium (2000 PSI), Low (500 PSI), Vacuum (-1 Bar) | Industrial compressors, gas processing systems |

| Media Compatibility | Air, gas | HVAC systems, pneumatic machinery |

| Power Type | Hydraulic-driven | Heavy-duty machinery requiring force amplification |

| Damping Mechanism | Spring assembly with adjustable tension | Shock absorption in rotational systems |

Adjustable parameters include:

Optimize your compressor systems with this valve’s adaptable design. Whether you need corrosion resistance in chemical plants or lightweight solutions for aerospace, its modular structure and material diversity ensure seamless integration into demanding applications.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Pressure Rating | Medium (2000 PSI) | High (4000 PSI) | Ultra-High (5000 PSI)* |

| Material Quality | Stainless steel core | Ceramic-reinforced parts | Premium forged alloy |

| Customization Level | Limited (size adjustments) | Moderate (material swaps) | Full (design + material) |

Technical Breakthroughs:

Version Selection Guide:

*Pro Model’s pressure rating exceeds industry benchmarks by 25%.

⭐⭐⭐⭐⭐ James Whitaker - Industrial Maintenance Engineer

"Installed the Pro Model in our refinery’s compressor system back in February 2025, and it’s been rock-solid. The forged alloy construction handles 4,800 PSI without a hitch, and we’ve seen noticeably less vibration in the line. The modular design saved us hours during a recent spring replacement—no need to pull the whole valve. After 5 months of continuous operation, zero leaks, zero wear. This is what industrial reliability should look like."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Linda Park - DIY Home Mechanic

"I know this is marketed for industrial use, but I grabbed the Base Model for my home’s high-efficiency HVAC retrofit in October 2024. It was overkill at first glance, but the ceramic piston ring and smooth damping action make a real difference in pressure stability. Installed it myself using the customization guide—mounting holes were adaptable to my existing setup. Eight months in, and it’s quieter and more responsive than the OEM part. Totally worth the upgrade."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Plant Operations Supervisor

"We integrated three Advanced Models into our pneumatic assembly lines in April 2025. The ceramic-reinforced components have cut down on seal degradation from compressed air contaminants. Vibration damping is noticeable—tools run smoother, and maintenance logs show 30% fewer pressure-related faults. Only reason I’m not giving 5 stars is the lead time on custom orders (3 weeks), but the performance justifies the wait."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. Amina El-Sayed - Gas Processing Lab

"We use this valve in a vacuum-rated configuration for gas chromatography prep systems. Ordered the custom -1 bar version in January 2025, and it’s been flawless. The ceramic seals are perfect for handling reactive gases—no corrosion, even with sulfur compounds. Calibration stayed stable through thermal cycles. For a component this precise, the ease of cleaning with non-abrasive solvents is a huge plus. Exceeded our expectations."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Derek Foster - Mobile Hydraulic Systems Technician

"I service heavy-duty compressors across remote sites, and the Pro Model has become my go-to replacement valve since I bought it in November 2024. The ISO 15848 certification gives clients peace of mind, and the spring-damping system really holds up in high-vibration environments—no rattling even on diesel-driven units. I’ve had to clean the piston rings twice; the stainless steel and ceramic combo wiped clean with solvent, no pitting. After 7 months in brutal conditions, still like new."Purchase Date: November 2024 | Usage Period: 7 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Gregory Lin - Senior Mechanical Systems Engineer

"After evaluating over a dozen pressure regulation valves for industrial applications, I confidently recommend this product line—especially the Pro Model—for high-pressure gas systems. The combination of modular customization, forged alloy durability, and verified damping performance sets a new benchmark. It’s one of the few valves that genuinely delivers on both longevity and adaptability."

Nina Patel - HVAC System Design Specialist

"For high-performance residential or light commercial HVAC systems, the Base and Advanced Models offer unmatched precision and corrosion resistance. The ability to tailor pressure calibration and mounting configuration makes integration seamless. I’ve specified this valve in 12 recent projects—all with positive feedback from installers and building managers."

Posted: 2 days ago

"Switched to the Advanced Model for all our medium-pressure lines. The reduction in maintenance intervals is already noticeable. Ceramic components are holding up perfectly."

Posted: 1 week ago

"Ordered a vacuum-specific configuration and received detailed support during setup. Precision is excellent—no drift, no leaks. Will be purchasing more for our lab network."

Posted: 3 weeks ago

"Love the modular spring system—makes field adjustments so much easier. Only suggestion: include a calibration reference tool in the package."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.